The STAINLESS STEEL butterfly valve is a corrosion-resistant industrial valve with a PTFE-sealed disc, providing reliable tight shut‑off and smooth flow control in chemical and corrosive media service.

Working Principles

The stainless steel concentric groove 316L PTFE butterfly valve is commonly used in industries handling corrosive or aggressive fluids. It is suitable for chemical processing, such as acids and alkalis, pharmaceutical production for liquid formulation control, and food or beverage industries where non-reactive, hygienic materials are required. Its PTFE lining ensures chemical resistance, prevents leakage, and allows reliable operation in processes requiring durability and contamination-free flow control.

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

● Seats and seals comply with FDA approved

● Special gasket design, fluid free of residue

● Better acid proof, alkali proof

● Small torque, light weight,simple structure

● 360 degree installation

● 100% tested and inspected

● Cost-efficient leakage protection

● More than thirty thousand safety test

● Low pressure losses

● Thorough cleaning,Hygienic exterior design

● Minimize turbulence and maximize fluid flow trough

Sanitary Butterfly valve widely use in low and medium viscosity liquid for food and beverage, beer, dairy, pharmaceutical etc with high precision and purity requirements industries.

Working Principles

The stainless steel concentric groove 316L PTFE butterfly valve is commonly used in industries handling corrosive or aggressive fluids. It is suitable for chemical processing, such as acids and alkalis, pharmaceutical production for liquid formulation control, and food or beverage industries where non-reactive, hygienic materials are required. Its PTFE lining ensures chemical resistance, prevents leakage, and allows reliable operation in processes requiring durability and contamination-free flow control.

Feature and Specification

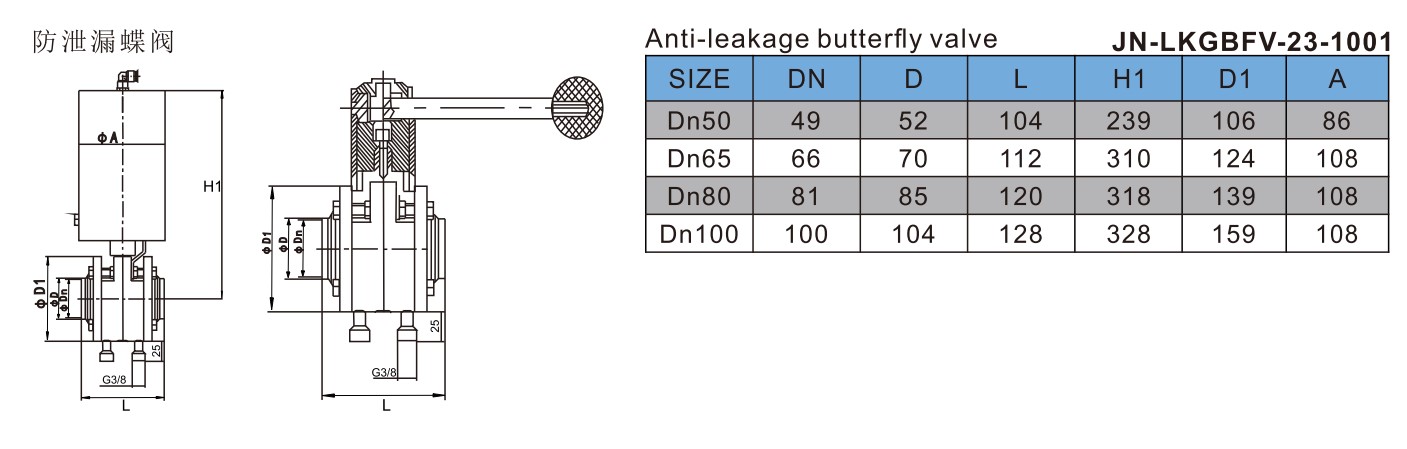

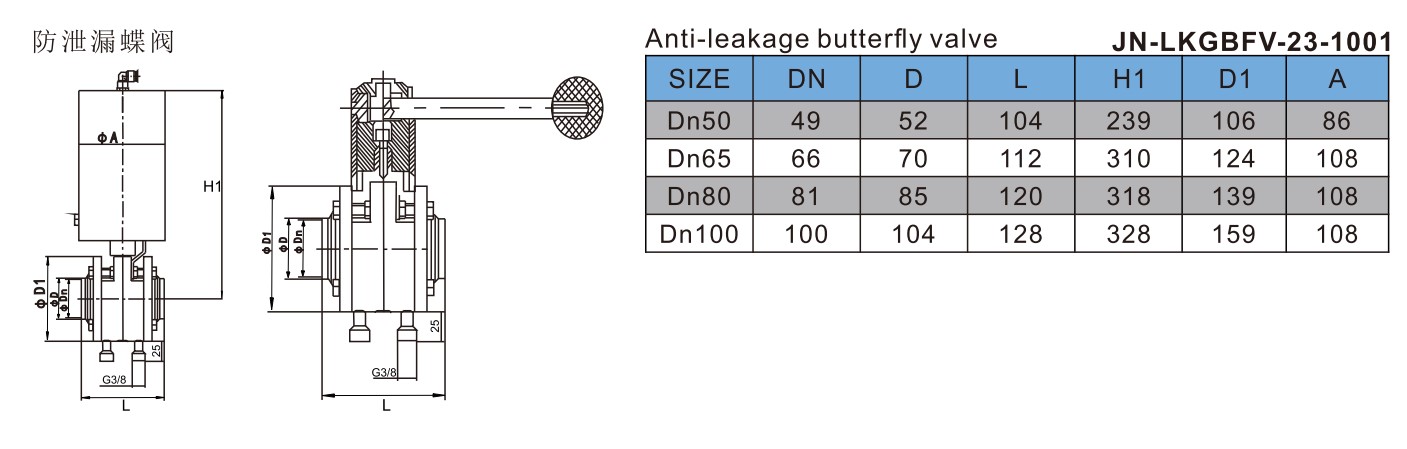

Stainless Steel Butterfly Valve Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● Seats and seals comply with FDA approved

● Special gasket design, fluid free of residue

● Better acid proof, alkali proof

● Small torque, light weight,simple structure

● 360 degree installation

● 100% tested and inspected

● Cost-efficient leakage protection

● More than thirty thousand safety test

● Low pressure losses

● Thorough cleaning,Hygienic exterior design

● Minimize turbulence and maximize fluid flow trough

Application

Sanitary Butterfly valve widely use in low and medium viscosity liquid for food and beverage, beer, dairy, pharmaceutical etc with high precision and purity requirements industries.