| Availability: | |

|---|---|

| Quantity: | |

JONENG

butterfly valves are available in manual or actuated types, with wafer or clamp connections. Common sizes center on DN25, using 304 or 316L stainless steel bodies, PTFE seats, hygienic design, corrosion resistance, and smooth, easy-to-clean internal surfaces.

The stainless steel wafer-type solenoid metering fine butterfly valve operates by using an electric solenoid to control the rotation of a small disc inside the valve body. When the solenoid is energized, it generates a magnetic force that moves the plunger, opening the disc to allow precise fluid flow. De-energizing the solenoid causes the plunger to return, closing the disc and stopping flow. The wafer-type design allows compact installation between flanges, while the fine disc and PTFE or metal seat provide accurate metering, low leakage, and smooth operation. This valve is ideal for dosing, chemical injection, or automated process control systems requiring precise flow regulation.

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Stainless steel body provides excellent corrosion resistance and long service life in fire water and harsh industrial environments.

Aluminum lever offers lightweight, quick manual operation, enabling fast shut-off or opening during emergency fire protection situations.

Lug style connection allows secure installation, supports end-of-line service, and ensures strong pipeline alignment and stability.

Resilient seat design delivers reliable sealing performance, minimizing leakage under frequent operation and pressure fluctuations.

Simple quarter-turn mechanism reduces maintenance requirements and ensures dependable, repeatable flow control performance.

The stainless steel DN300 eccentric rubber seat vacuum butterfly valve is widely used in industries requiring airtight flow control, such as vacuum packaging, pharmaceutical processing, and chemical manufacturing. For example, it can regulate air or gas flow in vacuum conveyors, control inert gas in chemical reactors, or maintain sterile conditions in pharmaceutical pipelines, ensuring reliable sealing and preventing contamination in sensitive processes.

Working Principles

The stainless steel wafer-type solenoid metering fine butterfly valve operates by using an electric solenoid to control the rotation of a small disc inside the valve body. When the solenoid is energized, it generates a magnetic force that moves the plunger, opening the disc to allow precise fluid flow. De-energizing the solenoid causes the plunger to return, closing the disc and stopping flow. The wafer-type design allows compact installation between flanges, while the fine disc and PTFE or metal seat provide accurate metering, low leakage, and smooth operation. This valve is ideal for dosing, chemical injection, or automated process control systems requiring precise flow regulation.

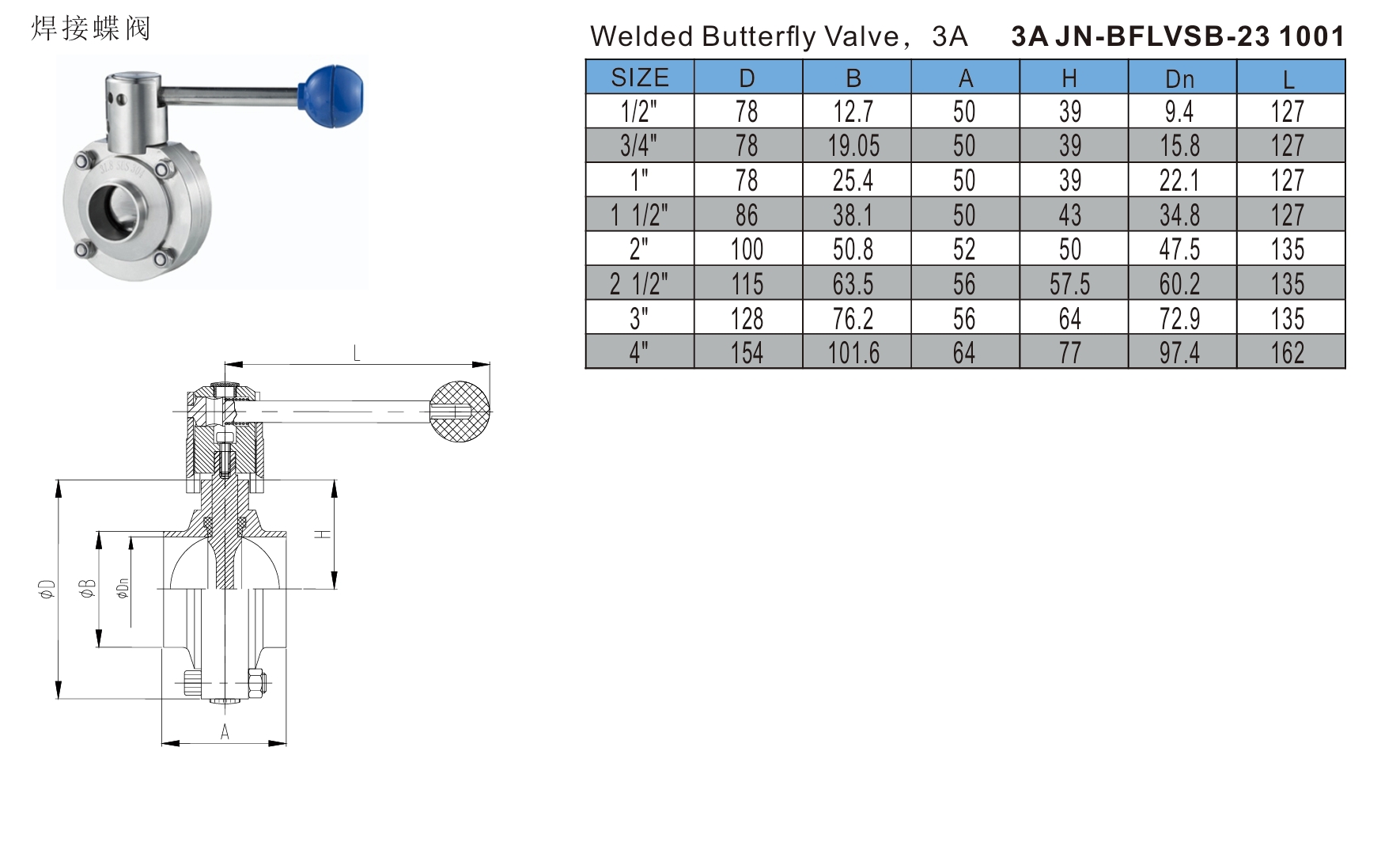

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

Stainless steel body provides excellent corrosion resistance and long service life in fire water and harsh industrial environments.

Aluminum lever offers lightweight, quick manual operation, enabling fast shut-off or opening during emergency fire protection situations.

Lug style connection allows secure installation, supports end-of-line service, and ensures strong pipeline alignment and stability.

Resilient seat design delivers reliable sealing performance, minimizing leakage under frequent operation and pressure fluctuations.

Simple quarter-turn mechanism reduces maintenance requirements and ensures dependable, repeatable flow control performance.

Application

The stainless steel DN300 eccentric rubber seat vacuum butterfly valve is widely used in industries requiring airtight flow control, such as vacuum packaging, pharmaceutical processing, and chemical manufacturing. For example, it can regulate air or gas flow in vacuum conveyors, control inert gas in chemical reactors, or maintain sterile conditions in pharmaceutical pipelines, ensuring reliable sealing and preventing contamination in sensitive processes.