| Availability: | |

|---|---|

| Quantity: | |

JN-AS-1001

JONENG

8481804090

Stainless Steel Sanitary Pneumatic Welded Angle Seat Valve For Pharmaceutical

The design of the stainless steel sanitary pneumatic angle seat valve is to provide more efficient fluid control by optimizing the angle seat structure, while reducing the resistance and turbulence of the fluid channel to ensure the smoothness of the fluid when passing. Its pneumatic drive function enables the valve to automatically respond to pressure changes, reduce manual operation, and thus improve the level of production automation and precision. This type of valve is particularly suitable for environments with extremely high requirements for hygiene and aseptic conditions, can effectively prevent contamination, and is easy to clean. Through special sealing design and dead angle-free structure, it can reduce material residue and ensure the fluid is pure and pollution-free. It is widely used in food, beverage, pharmaceutical and other industries to meet strict hygiene standards and high fluid control requirements.

Working Principles

The working principle of stainless steel sanitary pneumatic angle seat valve is based on pneumatic drive system and angle seat design. When the pneumatic signal is transmitted to the valve, the gas in the cylinder pushes the piston to move, thereby driving the valve stem to move up and down to control the opening and closing of the valve. The pneumatic angle seat valve adopts an angle seat structure to minimize the flow resistance of the fluid inside the valve and ensure the smoothness of the fluid when passing through. In the normally closed pneumatic angle seat valve, the pneumatic signal opens the valve, while in the normally open valve, the valve remains open when there is no pneumatic signal.

The options of stainless steel sanitary pneumatic angle seat valve include:

Valve body material: 304 or 316L stainless steel, suitable for different corrosion resistance requirements.

Connection method: thread, clamp, welding or flange connection.

Sealing material: EPDM, FKM, PTFE, etc., suitable for different media and temperatures.

Caliber specification: Various sizes are available to adapt to different pipe diameters.

Actuator: Single acting (spring return) or double acting (pneumatic control).

Flow direction: Horizontal or vertical installation to meet different flow requirements.

Surface treatment: Electrolytic polishing or mirror polishing to improve hygiene level.

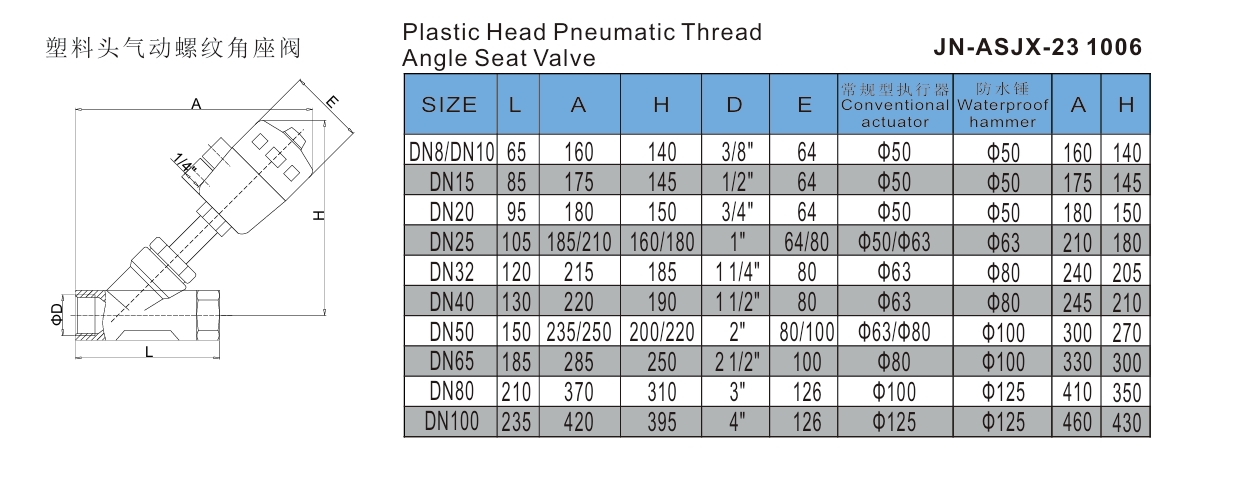

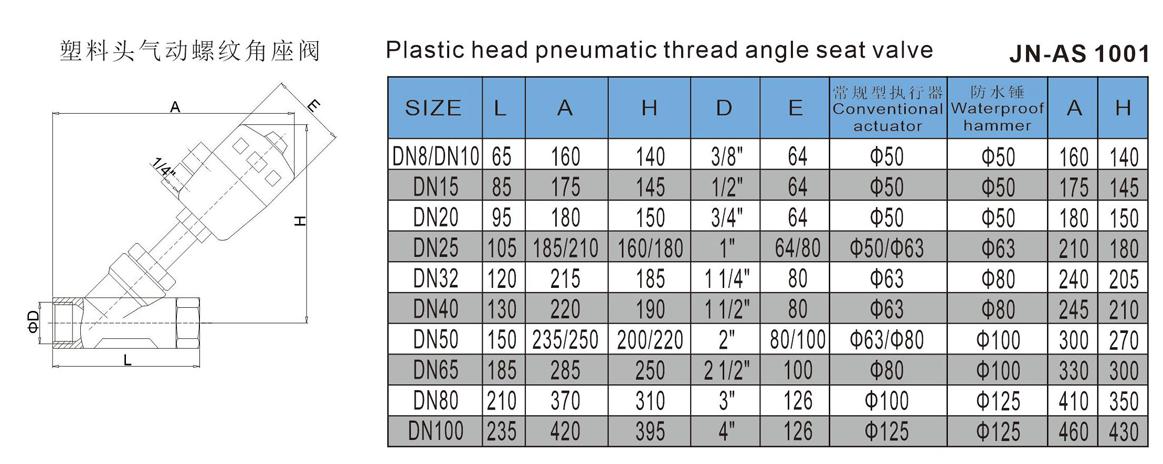

Specification Chart

Max Working Pressure | 1.6MPa |

Medium Temperature | -10℃~+180℃ |

Ambient Temperature | -10℃~+55℃ |

Body Materials | CF8M(SS316),CF8(SS304) |

Sealing Material | PTFE |

Operation | Normally Closed, Normally Open, Double-acting or Manually |

Connection End | Female, Weld,Clamp, Flange or on request |

Size Range | DN10-DN100 |

Surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Standards | DIN, SMS, ISO / IDF, BS / RJT, ASME / BPE. |

Control type | Single acting, double acting |

Features

● The stainless steel sanitary pneumatic angle seat valve adopts an asymmetric flow channel design, optimizes the flow velocity distribution through fluid dynamics simulation, reduces turbulence and local pressure drop, and is especially suitable for high viscosity or particle-containing media.

● The inner wall of the stainless steel sanitary pneumatic angle seat valve body is coated with nano-hydrophobic material to reduce the adhesion of the medium, prevent residue and crystallization, and is suitable for syrup, protein and other easy-to-adhere fluids.

● The stainless steel sanitary pneumatic angle seat valve is equipped with a main and auxiliary double seal structure at the valve stem and valve seat. When the main seal fails, the auxiliary seal is automatically enabled, and zero leakage can still be guaranteed under extreme conditions.

● The stainless steel sanitary pneumatic angle seat valve adopts ultra-low temperature compatible sealing rings and anti-cold brittle valve body materials, which can work stably in a -50℃ environment and is suitable for frozen food or low-temperature biological agent transmission.

● The pneumatic actuator of the stainless steel sanitary pneumatic angle seat valve has a built-in multi-stage buffer module to reduce the impact force of the valve core closing, avoid water hammer effect, and extend the life of the valve.

● The flow channel and valve cavity design of the stainless steel sanitary pneumatic angle seat valve incorporate acoustic muffler holes to reduce the noise generated by high-speed fluids and meet the low-noise requirements of clean rooms.

Application

Stainless steel sanitary pneumatic angle seat valves are widely used in the following industries: Food industry: used for fluid control of beverages, dairy products, condiments, etc., to ensure high hygiene standards. Pharmaceutical industry: suitable for the transmission of media such as liquid medicine, vaccines, sterile water, etc., to meet GMP requirements. Bioengineering: used for high-cleanliness fluid control such as cell culture fluid and culture medium. Cosmetic industry: conveying emulsions, essences and other products to ensure pollution-free and high purity. Chemical industry: handling corrosive chemicals and high-purity solvents, with strong corrosion resistance. Semiconductor industry: used for ultrapure water and high-purity gas delivery to meet clean room requirements. Brewing industry: used for precise control of fermented liquids such as beer and wine.

Working Principles

The working principle of stainless steel sanitary pneumatic angle seat valve is based on pneumatic drive system and angle seat design. When the pneumatic signal is transmitted to the valve, the gas in the cylinder pushes the piston to move, thereby driving the valve stem to move up and down to control the opening and closing of the valve. The pneumatic angle seat valve adopts an angle seat structure to minimize the flow resistance of the fluid inside the valve and ensure the smoothness of the fluid when passing through. In the normally closed pneumatic angle seat valve, the pneumatic signal opens the valve, while in the normally open valve, the valve remains open when there is no pneumatic signal.

The options of stainless steel sanitary pneumatic angle seat valve include:

Valve body material: 304 or 316L stainless steel, suitable for different corrosion resistance requirements.

Connection method: thread, clamp, welding or flange connection.

Sealing material: EPDM, FKM, PTFE, etc., suitable for different media and temperatures.

Caliber specification: Various sizes are available to adapt to different pipe diameters.

Actuator: Single acting (spring return) or double acting (pneumatic control).

Flow direction: Horizontal or vertical installation to meet different flow requirements.

Surface treatment: Electrolytic polishing or mirror polishing to improve hygiene level.

Specification Chart

Max Working Pressure | 1.6MPa |

Medium Temperature | -10℃~+180℃ |

Ambient Temperature | -10℃~+55℃ |

Body Materials | CF8M(SS316),CF8(SS304) |

Sealing Material | PTFE |

Operation | Normally Closed, Normally Open, Double-acting or Manually |

Connection End | Female, Weld,Clamp, Flange or on request |

Size Range | DN10-DN100 |

Surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Standards | DIN, SMS, ISO / IDF, BS / RJT, ASME / BPE. |

Control type | Single acting, double acting |

Features

● The stainless steel sanitary pneumatic angle seat valve adopts an asymmetric flow channel design, optimizes the flow velocity distribution through fluid dynamics simulation, reduces turbulence and local pressure drop, and is especially suitable for high viscosity or particle-containing media.

● The inner wall of the stainless steel sanitary pneumatic angle seat valve body is coated with nano-hydrophobic material to reduce the adhesion of the medium, prevent residue and crystallization, and is suitable for syrup, protein and other easy-to-adhere fluids.

● The stainless steel sanitary pneumatic angle seat valve is equipped with a main and auxiliary double seal structure at the valve stem and valve seat. When the main seal fails, the auxiliary seal is automatically enabled, and zero leakage can still be guaranteed under extreme conditions.

● The stainless steel sanitary pneumatic angle seat valve adopts ultra-low temperature compatible sealing rings and anti-cold brittle valve body materials, which can work stably in a -50℃ environment and is suitable for frozen food or low-temperature biological agent transmission.

● The pneumatic actuator of the stainless steel sanitary pneumatic angle seat valve has a built-in multi-stage buffer module to reduce the impact force of the valve core closing, avoid water hammer effect, and extend the life of the valve.

● The flow channel and valve cavity design of the stainless steel sanitary pneumatic angle seat valve incorporate acoustic muffler holes to reduce the noise generated by high-speed fluids and meet the low-noise requirements of clean rooms.

Application

Stainless steel sanitary pneumatic angle seat valves are widely used in the following industries: Food industry: used for fluid control of beverages, dairy products, condiments, etc., to ensure high hygiene standards. Pharmaceutical industry: suitable for the transmission of media such as liquid medicine, vaccines, sterile water, etc., to meet GMP requirements. Bioengineering: used for high-cleanliness fluid control such as cell culture fluid and culture medium. Cosmetic industry: conveying emulsions, essences and other products to ensure pollution-free and high purity. Chemical industry: handling corrosive chemicals and high-purity solvents, with strong corrosion resistance. Semiconductor industry: used for ultrapure water and high-purity gas delivery to meet clean room requirements. Brewing industry: used for precise control of fermented liquids such as beer and wine.