| Availability: | |

|---|---|

| Quantity: | |

JN-FDV1001

JONENG

8481804090

Stainless Steel Sanitary Food Grade Quick-install Pneumatic Reversing Valve

The stainless steel sanitary quick-install pneumatic reversing valve is designed to provide an efficient, convenient and hygienic solution in pipeline systems where the flow direction of the fluid needs to be quickly switched. It uses pneumatic drive to accurately control the fluid path in the automated production process to avoid manual intervention. It also has the function of quick disassembly and installation to meet the high-frequency needs of cleaning and maintenance. Its design is particularly suitable for production lines where the flow direction of fluids changes frequently, such as in the food, beverage, pharmaceutical and other industries, ensuring efficient, stable and safe operation of the system and maintaining high hygiene standards.

Working Principles

The working principle of the stainless steel sanitary quick-install pneumatic reversing valve is to switch the flow direction of the fluid based on pneumatic drive. First, when the control system provides air pressure through the air source, the gas enters the pneumatic chamber inside the valve body, pushing the valve core or piston to move. According to the direction of the air pressure, the valve core will change the channel position of the fluid, thereby switching the flow path of the fluid. Usually, the valve is designed as a two-way pneumatic drive, and the valve switching action is achieved by controlling the air pressure. When the air pressure changes, the valve core will automatically return to the initial position, close a channel and open another channel, thereby achieving the direction control of the fluid.

The options of the stainless steel sanitary quick-install pneumatic reversing valve include:

Drive mode: single-acting, double-acting pneumatic drive.

Number of channels: 2/2 channels, 3/2 channels, 4/2 channels, 5/2 channels.

Connection mode: quick connection, threaded connection, flange connection.

Sealing material: EPDM, PTFE, Viton.

Operation mode: automatic control, manual operation.

Pressure range: low pressure, high pressure selection.

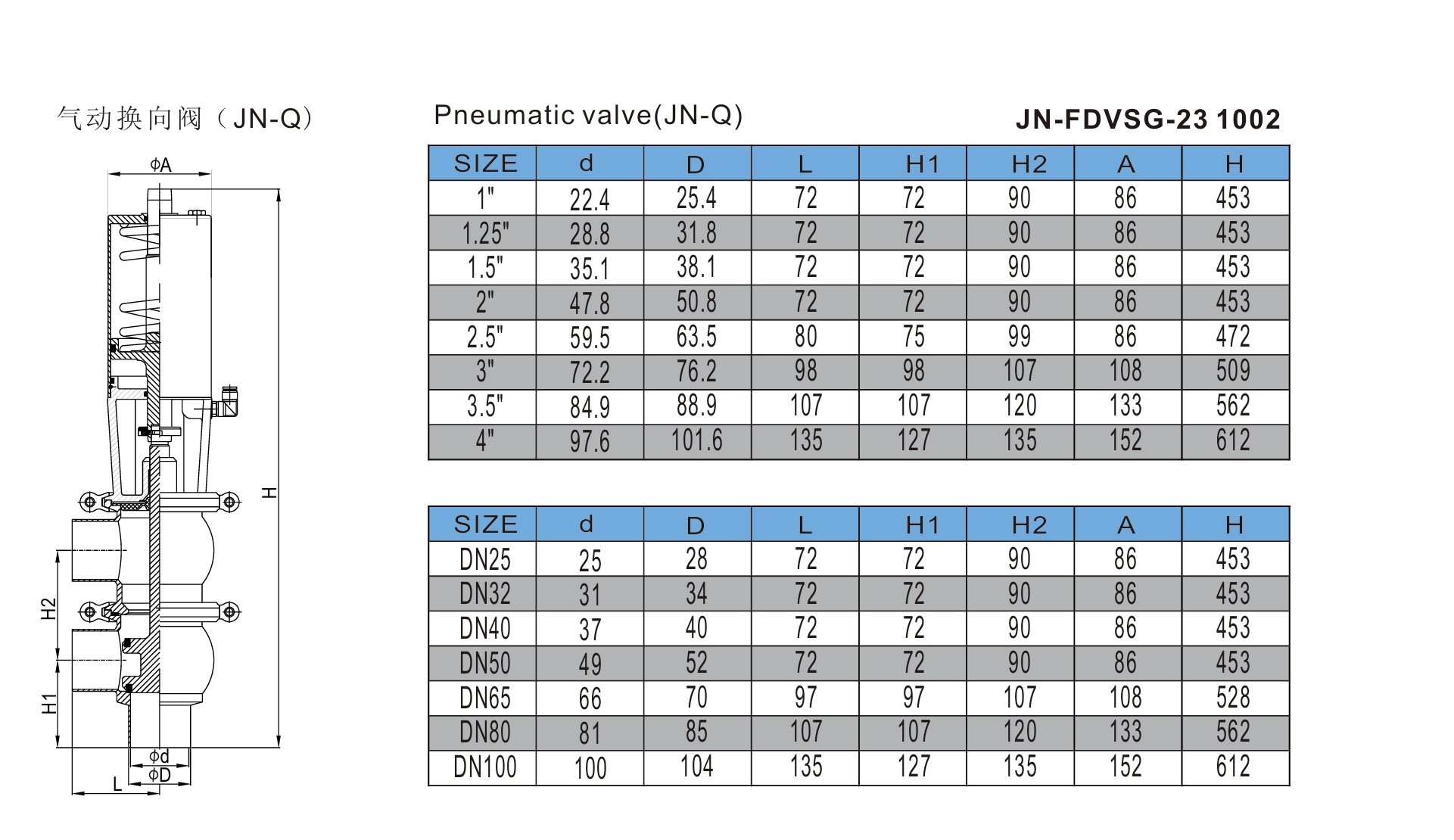

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary quick-install pneumatic reversing valve is equipped with a precise pneumatic drive system that can finely adjust the valve opening to ensure accurate switching of the fluid flow direction.

● The inner and outer surfaces of the stainless steel sanitary quick-install pneumatic reversing valve adopt an electrolytic polishing process to improve the surface finish and anti-pollution ability, and reduce the possibility of fluid residue and bacterial growth.

● The pneumatic drive system design of the stainless steel sanitary quick-install pneumatic reversing valve has the ability to adapt to multiple gas sources, and can operate stably under different pressures and gas source types, providing higher system compatibility.

● The stainless steel sanitary quick-install pneumatic reversing valve adopts a quick-change connector design, which can be disassembled, installed or replaced within a few minutes, saving a lot of maintenance time.

● The stainless steel sanitary quick-install pneumatic reversing valve has a self-sealing function, which automatically adjusts the sealing state during the installation process to avoid leakage problems caused by poor sealing.

● The stainless steel sanitary quick-install pneumatic reversing valve adopts a specially designed sealing ring and valve body structure to ensure leakage-free operation even under high pressure or extreme temperature.

Application

Stainless steel sanitary quick-install pneumatic reversing valves are widely used in the following industries: Food processing: used to control the flow direction of liquids to keep the production line smooth. Pharmaceutical industry: accurately control the fluid path to ensure safe and pollution-free production process. Beverage manufacturing: switch the fluid direction to optimize production efficiency and hygiene requirements. Chemical industry: control the flow direction of chemical raw materials to prevent cross contamination. Water treatment: adjust the water flow direction to ensure stable operation of the system. Dairy production: control the flow of emulsions to prevent bacterial contamination.

Working Principles

The working principle of the stainless steel sanitary quick-install pneumatic reversing valve is to switch the flow direction of the fluid based on pneumatic drive. First, when the control system provides air pressure through the air source, the gas enters the pneumatic chamber inside the valve body, pushing the valve core or piston to move. According to the direction of the air pressure, the valve core will change the channel position of the fluid, thereby switching the flow path of the fluid. Usually, the valve is designed as a two-way pneumatic drive, and the valve switching action is achieved by controlling the air pressure. When the air pressure changes, the valve core will automatically return to the initial position, close a channel and open another channel, thereby achieving the direction control of the fluid.

The options of the stainless steel sanitary quick-install pneumatic reversing valve include:

Drive mode: single-acting, double-acting pneumatic drive.

Number of channels: 2/2 channels, 3/2 channels, 4/2 channels, 5/2 channels.

Connection mode: quick connection, threaded connection, flange connection.

Sealing material: EPDM, PTFE, Viton.

Operation mode: automatic control, manual operation.

Pressure range: low pressure, high pressure selection.

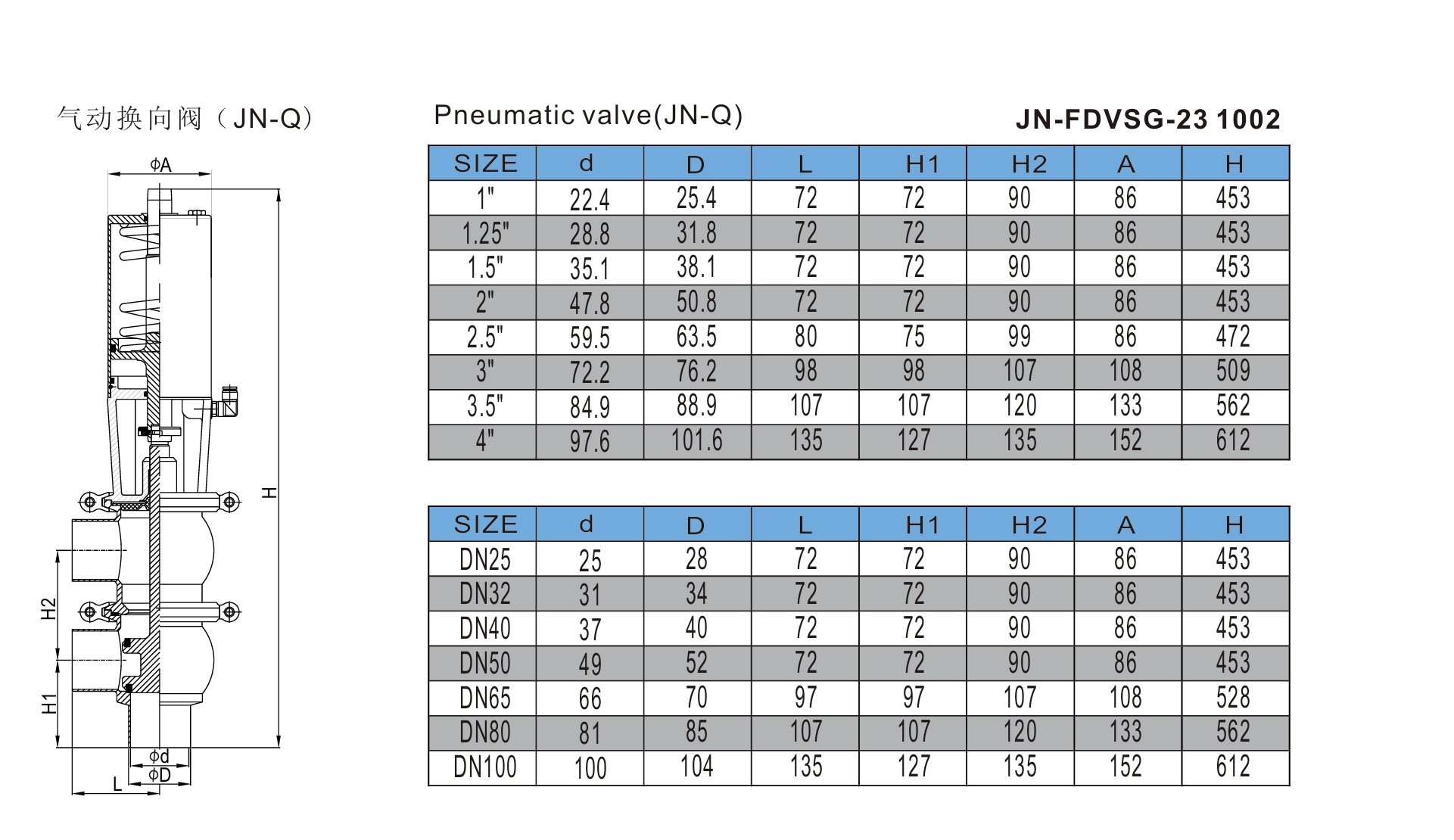

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary quick-install pneumatic reversing valve is equipped with a precise pneumatic drive system that can finely adjust the valve opening to ensure accurate switching of the fluid flow direction.

● The inner and outer surfaces of the stainless steel sanitary quick-install pneumatic reversing valve adopt an electrolytic polishing process to improve the surface finish and anti-pollution ability, and reduce the possibility of fluid residue and bacterial growth.

● The pneumatic drive system design of the stainless steel sanitary quick-install pneumatic reversing valve has the ability to adapt to multiple gas sources, and can operate stably under different pressures and gas source types, providing higher system compatibility.

● The stainless steel sanitary quick-install pneumatic reversing valve adopts a quick-change connector design, which can be disassembled, installed or replaced within a few minutes, saving a lot of maintenance time.

● The stainless steel sanitary quick-install pneumatic reversing valve has a self-sealing function, which automatically adjusts the sealing state during the installation process to avoid leakage problems caused by poor sealing.

● The stainless steel sanitary quick-install pneumatic reversing valve adopts a specially designed sealing ring and valve body structure to ensure leakage-free operation even under high pressure or extreme temperature.

Application

Stainless steel sanitary quick-install pneumatic reversing valves are widely used in the following industries: Food processing: used to control the flow direction of liquids to keep the production line smooth. Pharmaceutical industry: accurately control the fluid path to ensure safe and pollution-free production process. Beverage manufacturing: switch the fluid direction to optimize production efficiency and hygiene requirements. Chemical industry: control the flow direction of chemical raw materials to prevent cross contamination. Water treatment: adjust the water flow direction to ensure stable operation of the system. Dairy production: control the flow of emulsions to prevent bacterial contamination.