| Availability: | |

|---|---|

| Quantity: | |

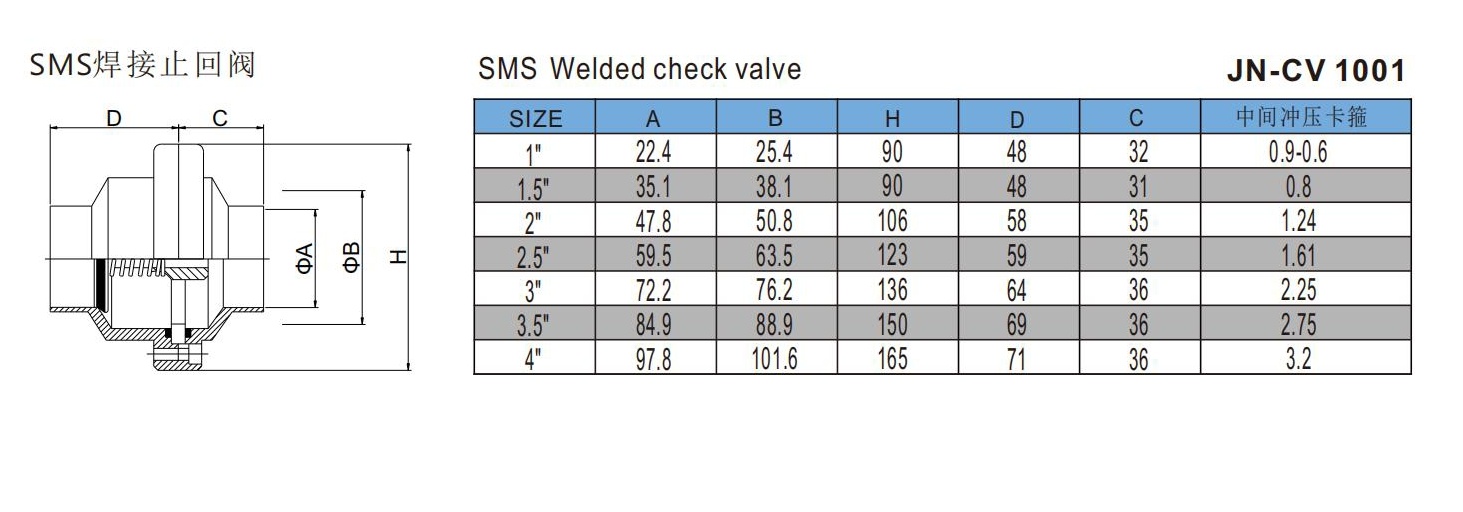

JN-CV 1001

JONENG

8481804090

Sanitary Stainless Steel Double Flange Clamp Check Valve

Sanitary Stainless Steel Double Flange Clamp Check Valve is a one-way valve designed to prevent backflow in piping systems. Its double flange clamp design ensures secure, leak-free installation, while the stainless steel construction provides durability and hygienic operation in sanitary applications.

Working Principles

The working principle of a Sanitary Stainless Steel Double Flange Clamp Check Valve is based on allowing fluid to flow in one direction while preventing reverse flow. When fluid moves forward through the valve, it pushes the internal disc or flap away from the seat, opening the passage and enabling smooth flow. If the fluid attempts to reverse, the disc is forced back against the seat by the reverse pressure, creating a tight seal that prevents backflow. The double flange clamp design provides secure installation and easy maintenance, while the stainless steel construction ensures corrosion resistance and hygienic operation. This valve is ideal for sanitary pipelines in food, beverage, and pharmaceutical applications.

Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries | |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred | |

The min. pressure difference is 0.08bar to open the valve | |

Flow direction is from the bottom to the top side only | |

Precision machined body, stem, disc, free draining | |

Disc tapered for smooth body and reduce draining | |

The check valves can not be used for sticky ,adhesive, viscous products. | |

Features

Made from high-quality stainless steel, providing excellent corrosion resistance and long-lasting durability in sanitary fluid systems.

Double flange clamp design ensures secure, leak-free installation and allows easy disassembly for maintenance.

One-way check mechanism prevents backflow, protecting pumps, pipelines, and equipment from damage.

Smooth internal surfaces and sanitary construction minimize contamination risks and support hygienic operation.

Compact and robust design enables reliable performance under frequent flow cycles in food, beverage, and pharmaceutical applications

Application

Stainless steel sanitary welded check valves are widely used in the following industries: Food industry: prevent fluid backflow and ensure the hygiene and safety of beverages and dairy products. Pharmaceutical industry: ensure the one-way flow of pure water and solvents to prevent cross contamination. Cosmetic industry: avoid backflow contamination of products such as emulsions and pastes during production. Bioengineering: control the one-way flow of important fluids such as fermentation liquid and culture medium. Fine chemicals: prevent the backflow of high-purity chemicals and maintain product quality. Water treatment industry: ensure the one-way flow of pure water and wastewater treatment systems.

Working Principles

The working principle of a Sanitary Stainless Steel Double Flange Clamp Check Valve is based on allowing fluid to flow in one direction while preventing reverse flow. When fluid moves forward through the valve, it pushes the internal disc or flap away from the seat, opening the passage and enabling smooth flow. If the fluid attempts to reverse, the disc is forced back against the seat by the reverse pressure, creating a tight seal that prevents backflow. The double flange clamp design provides secure installation and easy maintenance, while the stainless steel construction ensures corrosion resistance and hygienic operation. This valve is ideal for sanitary pipelines in food, beverage, and pharmaceutical applications.

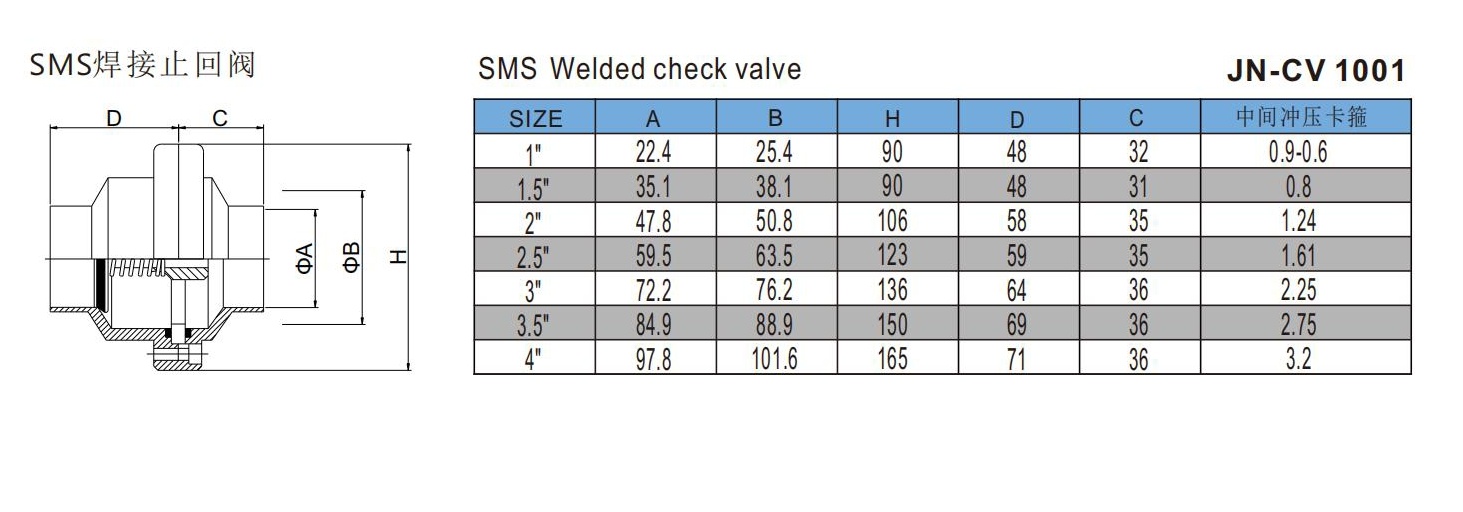

Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries | |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred | |

The min. pressure difference is 0.08bar to open the valve | |

Flow direction is from the bottom to the top side only | |

Precision machined body, stem, disc, free draining | |

Disc tapered for smooth body and reduce draining | |

The check valves can not be used for sticky ,adhesive, viscous products. | |

Features

Made from high-quality stainless steel, providing excellent corrosion resistance and long-lasting durability in sanitary fluid systems.

Double flange clamp design ensures secure, leak-free installation and allows easy disassembly for maintenance.

One-way check mechanism prevents backflow, protecting pumps, pipelines, and equipment from damage.

Smooth internal surfaces and sanitary construction minimize contamination risks and support hygienic operation.

Compact and robust design enables reliable performance under frequent flow cycles in food, beverage, and pharmaceutical applications

Application

Stainless steel sanitary welded check valves are widely used in the following industries: Food industry: prevent fluid backflow and ensure the hygiene and safety of beverages and dairy products. Pharmaceutical industry: ensure the one-way flow of pure water and solvents to prevent cross contamination. Cosmetic industry: avoid backflow contamination of products such as emulsions and pastes during production. Bioengineering: control the one-way flow of important fluids such as fermentation liquid and culture medium. Fine chemicals: prevent the backflow of high-purity chemicals and maintain product quality. Water treatment industry: ensure the one-way flow of pure water and wastewater treatment systems.