| Availability: | |

|---|---|

| Quantity: | |

JONENG

Sanitary Stainless Steel Manual Welded rubber Diaphragm Valve

The Sanitary Stainless Steel Manual Welded Rubber Diaphragm Valve is a hygienic valve operated manually. Its welded rubber diaphragm provides leak-free sealing, corrosion resistance, and reliable flow control, making it suitable for food, pharmaceutical, and high-purity fluid systems requiring sanitary handling

Working Principles

The Sanitary Stainless Steel Manual Welded Rubber Diaphragm Valve operates by manually turning a handwheel or lever, which moves the diaphragm against the valve seat to control flow. The welded rubber diaphragm acts as a flexible barrier, sealing the valve body and preventing leaks while isolating the fluid from mechanical parts. Lifting the diaphragm opens the flow path, allowing liquids or gases to pass through smoothly. Its welded design ensures durability and corrosion resistance, while the manual operation allows precise, controlled regulation. This mechanism provides reliable, hygienic, and leak-free performance, making it ideal for food, pharmaceutical, and high-purity processing applications

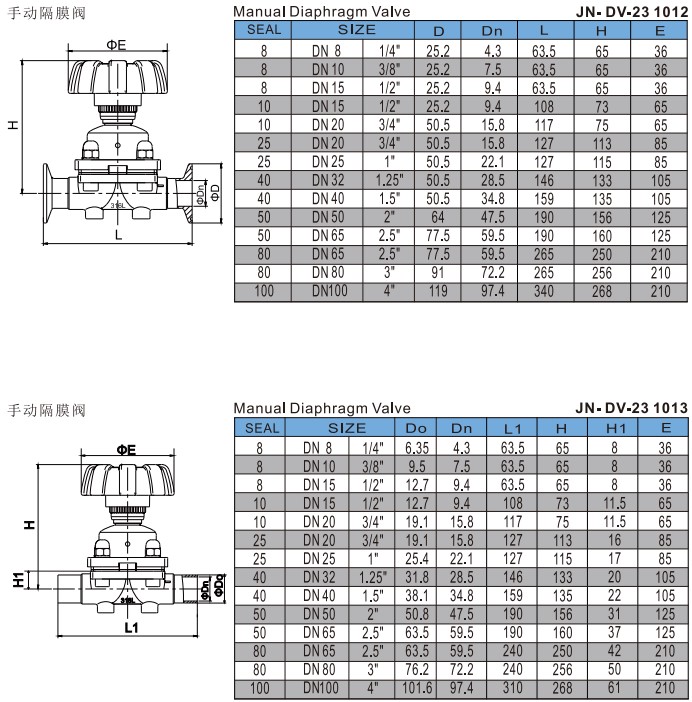

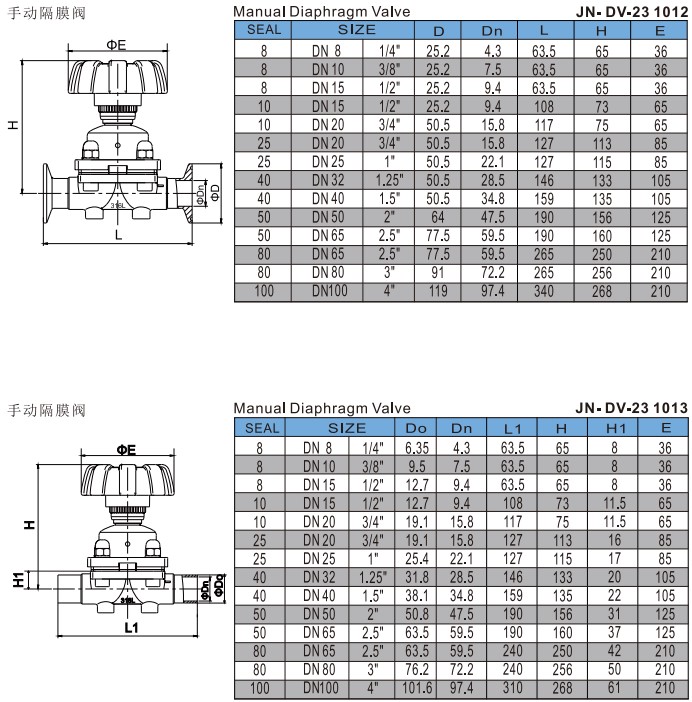

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

Welded Rubber Diaphragm – Provides leak-free sealing, flexibility, and durability, ensuring reliable operation in sanitary fluid systems.

Manual Operation – Handwheel or lever allows precise and controlled flow regulation without external power.

Stainless Steel Construction – Corrosion-resistant and durable, suitable for hygienic environments in food, pharmaceutical, and high-purity systems.

Hygienic Design – Smooth surfaces and sanitary construction minimize contamination risk and facilitate cleaning.

Reliable Shutoff – The diaphragm ensures tight sealing against the valve seat, preventing leaks and maintaining system integrity.

Easy Maintenance – Simple design allows quick inspection, diaphragm replacement, and cleaning, supporting efficient operation and hygiene

Application

The Sanitary Stainless Steel Manual Welded Rubber Diaphragm Valve is widely used in industries requiring hygienic and leak-free flow control. Typical applications include food and beverage processing, pharmaceutical production, biotechnology, and high-purity water or chemical systems, where manual precision and sanitary operation are essential

Working Principles

The Sanitary Stainless Steel Manual Welded Rubber Diaphragm Valve operates by manually turning a handwheel or lever, which moves the diaphragm against the valve seat to control flow. The welded rubber diaphragm acts as a flexible barrier, sealing the valve body and preventing leaks while isolating the fluid from mechanical parts. Lifting the diaphragm opens the flow path, allowing liquids or gases to pass through smoothly. Its welded design ensures durability and corrosion resistance, while the manual operation allows precise, controlled regulation. This mechanism provides reliable, hygienic, and leak-free performance, making it ideal for food, pharmaceutical, and high-purity processing applications

Feature and Specification

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

Welded Rubber Diaphragm – Provides leak-free sealing, flexibility, and durability, ensuring reliable operation in sanitary fluid systems.

Manual Operation – Handwheel or lever allows precise and controlled flow regulation without external power.

Stainless Steel Construction – Corrosion-resistant and durable, suitable for hygienic environments in food, pharmaceutical, and high-purity systems.

Hygienic Design – Smooth surfaces and sanitary construction minimize contamination risk and facilitate cleaning.

Reliable Shutoff – The diaphragm ensures tight sealing against the valve seat, preventing leaks and maintaining system integrity.

Easy Maintenance – Simple design allows quick inspection, diaphragm replacement, and cleaning, supporting efficient operation and hygiene

Application

The Sanitary Stainless Steel Manual Welded Rubber Diaphragm Valve is widely used in industries requiring hygienic and leak-free flow control. Typical applications include food and beverage processing, pharmaceutical production, biotechnology, and high-purity water or chemical systems, where manual precision and sanitary operation are essential