| Availability: | |

|---|---|

| Quantity: | |

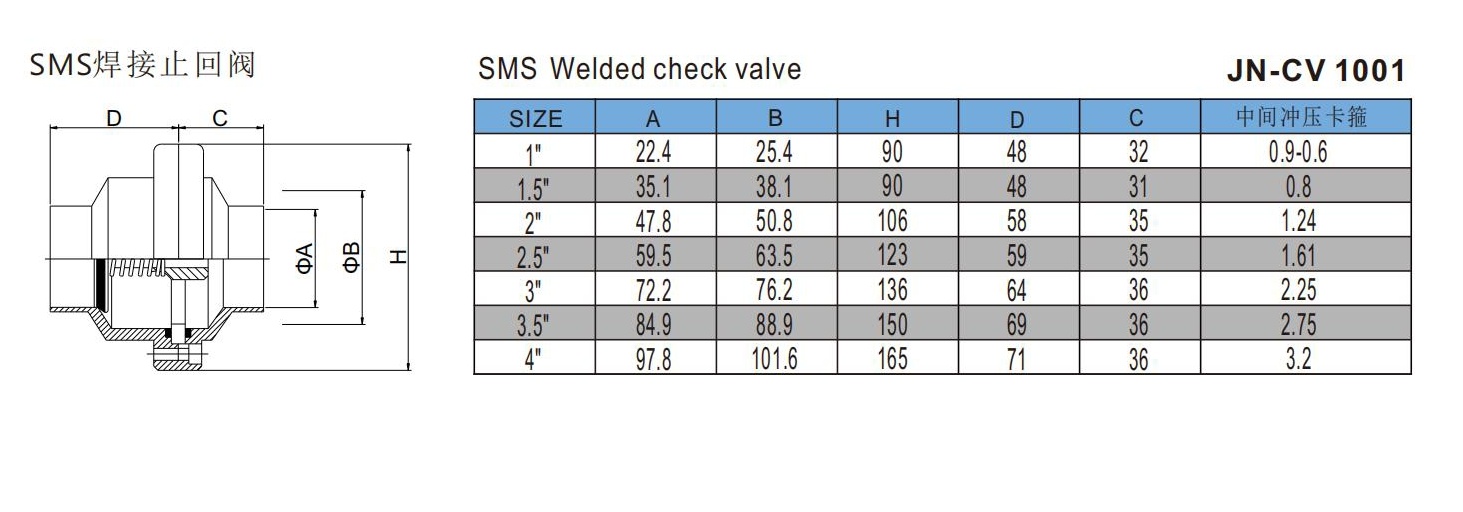

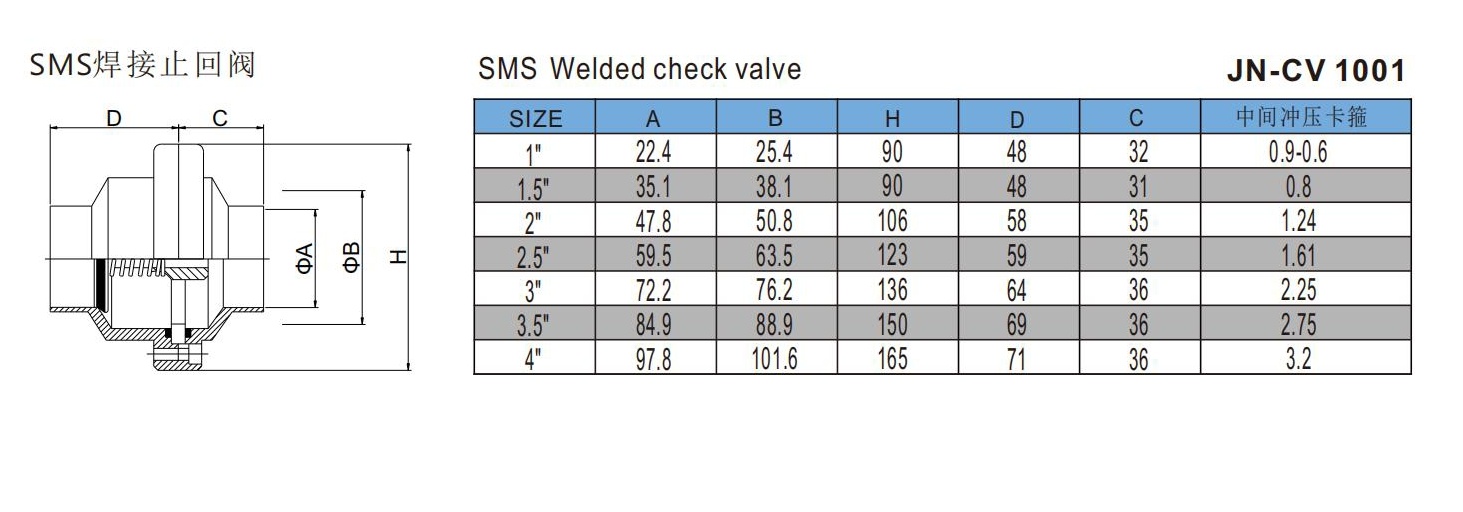

JN-CV 1001

JONENG

8481804090

Stainless steel sanitary mirror polished welded non return valve

The core of the design of the stainless steel sanitary welded check valve is to ensure the absolute one-way flow of the fluid system, avoid backflow contamination, and minimize flow resistance to improve the cleanliness and safety of the system. It is not just to prevent the backflow of the medium, but to meet the process requirements of high cleanliness, high precision, and high stability. Traditional check valves are prone to backflow contamination due to gaps, spring fatigue or seal aging, while the welded structure eliminates the microbial breeding points that may be brought by the assembly interface, ensuring the continuity of the sterile environment. In addition, the internal flow channel has been optimized for fluid dynamics to reduce turbulence and shear force, protect the activity of shear-sensitive media (such as dairy products, fermentation broth, serum), and is particularly suitable for industries that require extreme fluid control, such as food, pharmaceuticals, and bioengineering.

Working Principles

The working principle of the stainless steel sanitary welded check valve is based on unidirectional flow control. First, when the fluid enters from the inlet end of the valve, the pressure of the fluid pushes the valve disc to open, allowing the fluid to flow through the pipeline. At this time, the seal between the valve disc and the valve seat is fully opened, and the fluid is unobstructed. Secondly, when the fluid flow stops or flows in the opposite direction, the pressure in the valve will decrease rapidly, and the valve disc will automatically close under the action of the spring or gravity to prevent the liquid from flowing back. At this time, the seal between the valve disc and the valve seat is in close contact, preventing the medium from flowing back and ensuring the unidirectional flow of the pipeline system. The design of this valve usually does not require external power, automatically responds to changes in fluid pressure, provides efficient and durable backflow prevention function, and is widely used in sanitary systems that need to prevent backflow contamination.

Options for stainless steel sanitary welded check valves include:

Sealing materials: EPDM, PTFE, silicone, etc.

Connection method: welding, quick installation.

Valve disc type: spring type, gravity type, float type.

Fluid direction: vertical, horizontal installation.

Pressure range: can be customized according to system requirements.

Surface treatment: mirror polishing, roughness control.

Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries | |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred | |

The min. pressure difference is 0.08bar to open the valve | |

Flow direction is from the bottom to the top side only | |

Precision machined body, stem, disc, free draining | |

Disc tapered for smooth body and reduce draining | |

The check valves can not be used for sticky ,adhesive, viscous products. | |

Features

● The stainless steel sanitary welded check valve adopts a valve seat and valve disc design without dead zone to avoid fluid stagnation inside the valve, thereby preventing microbial growth and pollution accumulation, and ensuring sanitary conditions.

● The specially optimized flow channel shape of the stainless steel sanitary welded check valve reduces the resistance and turbulence during fluid flow, ensuring efficient and smooth fluid transmission.

● The special shape and surface treatment design of the stainless steel sanitary welded check valve disc can automatically remove the surface attachment of the disc when the fluid passes through, reducing the frequency of cleaning and maintenance.

● The welding joint design of the stainless steel sanitary welded check valve eliminates the dead corners at the traditional welding joints through smooth internal and external connections, reducing the accumulation of impurities.

● The stainless steel sanitary welded check valve body and disc are precisely polished with low surface roughness, which reduces liquid attachment, prevents material accumulation, and improves the purity and hygiene of the fluid.

● The stainless steel sanitary welded check valve adopts a floating disc design, which can be adaptively adjusted when the pressure fluctuates, ensuring the sealing effect when the disc is closed, and is not easily affected by pressure changes.

Application

Stainless steel sanitary welded check valves are widely used in the following industries: Food industry: prevent fluid backflow and ensure the hygiene and safety of beverages and dairy products. Pharmaceutical industry: ensure the one-way flow of pure water and solvents to prevent cross contamination. Cosmetic industry: avoid backflow contamination of products such as emulsions and pastes during production. Bioengineering: control the one-way flow of important fluids such as fermentation liquid and culture medium. Fine chemicals: prevent the backflow of high-purity chemicals and maintain product quality. Water treatment industry: ensure the one-way flow of pure water and wastewater treatment systems.

Working Principles

The working principle of the stainless steel sanitary welded check valve is based on unidirectional flow control. First, when the fluid enters from the inlet end of the valve, the pressure of the fluid pushes the valve disc to open, allowing the fluid to flow through the pipeline. At this time, the seal between the valve disc and the valve seat is fully opened, and the fluid is unobstructed. Secondly, when the fluid flow stops or flows in the opposite direction, the pressure in the valve will decrease rapidly, and the valve disc will automatically close under the action of the spring or gravity to prevent the liquid from flowing back. At this time, the seal between the valve disc and the valve seat is in close contact, preventing the medium from flowing back and ensuring the unidirectional flow of the pipeline system. The design of this valve usually does not require external power, automatically responds to changes in fluid pressure, provides efficient and durable backflow prevention function, and is widely used in sanitary systems that need to prevent backflow contamination.

Options for stainless steel sanitary welded check valves include:

Sealing materials: EPDM, PTFE, silicone, etc.

Connection method: welding, quick installation.

Valve disc type: spring type, gravity type, float type.

Fluid direction: vertical, horizontal installation.

Pressure range: can be customized according to system requirements.

Surface treatment: mirror polishing, roughness control.

Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries | |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred | |

The min. pressure difference is 0.08bar to open the valve | |

Flow direction is from the bottom to the top side only | |

Precision machined body, stem, disc, free draining | |

Disc tapered for smooth body and reduce draining | |

The check valves can not be used for sticky ,adhesive, viscous products. | |

Features

● The stainless steel sanitary welded check valve adopts a valve seat and valve disc design without dead zone to avoid fluid stagnation inside the valve, thereby preventing microbial growth and pollution accumulation, and ensuring sanitary conditions.

● The specially optimized flow channel shape of the stainless steel sanitary welded check valve reduces the resistance and turbulence during fluid flow, ensuring efficient and smooth fluid transmission.

● The special shape and surface treatment design of the stainless steel sanitary welded check valve disc can automatically remove the surface attachment of the disc when the fluid passes through, reducing the frequency of cleaning and maintenance.

● The welding joint design of the stainless steel sanitary welded check valve eliminates the dead corners at the traditional welding joints through smooth internal and external connections, reducing the accumulation of impurities.

● The stainless steel sanitary welded check valve body and disc are precisely polished with low surface roughness, which reduces liquid attachment, prevents material accumulation, and improves the purity and hygiene of the fluid.

● The stainless steel sanitary welded check valve adopts a floating disc design, which can be adaptively adjusted when the pressure fluctuates, ensuring the sealing effect when the disc is closed, and is not easily affected by pressure changes.

Application

Stainless steel sanitary welded check valves are widely used in the following industries: Food industry: prevent fluid backflow and ensure the hygiene and safety of beverages and dairy products. Pharmaceutical industry: ensure the one-way flow of pure water and solvents to prevent cross contamination. Cosmetic industry: avoid backflow contamination of products such as emulsions and pastes during production. Bioengineering: control the one-way flow of important fluids such as fermentation liquid and culture medium. Fine chemicals: prevent the backflow of high-purity chemicals and maintain product quality. Water treatment industry: ensure the one-way flow of pure water and wastewater treatment systems.