| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless Steel DN80 ISO Y Type Sanitary Tank Bottom Valve

Stainless Steel DN80 ISO Y Type Sanitary Tank Bottom Valve is a hygienic discharge valve designed for tank outlets. Its Y-shaped flow path promotes smooth drainage, reduces residue, and ensures reliable, leak-free operation in sanitary and sterile processing applications

Working Principles

The working principle of a Stainless Steel DN80 ISO Y Type Sanitary Tank Bottom Valve involves controlling the flow at the tank outlet using a Y-shaped flow channel. When the valve is opened manually or via an actuator, the valve plug lifts away from the seat, allowing liquid to discharge smoothly through the DN80 outlet. The Y-type design minimizes turbulence and promotes complete drainage by gravity, reducing residual product and preventing contamination. Closing the valve presses the plug firmly against the seat, ensuring a tight seal and preventing backflow. This valve is designed for hygienic applications, allowing easy cleaning and maintaining sterility in food, beverage, and pharmaceutical processes

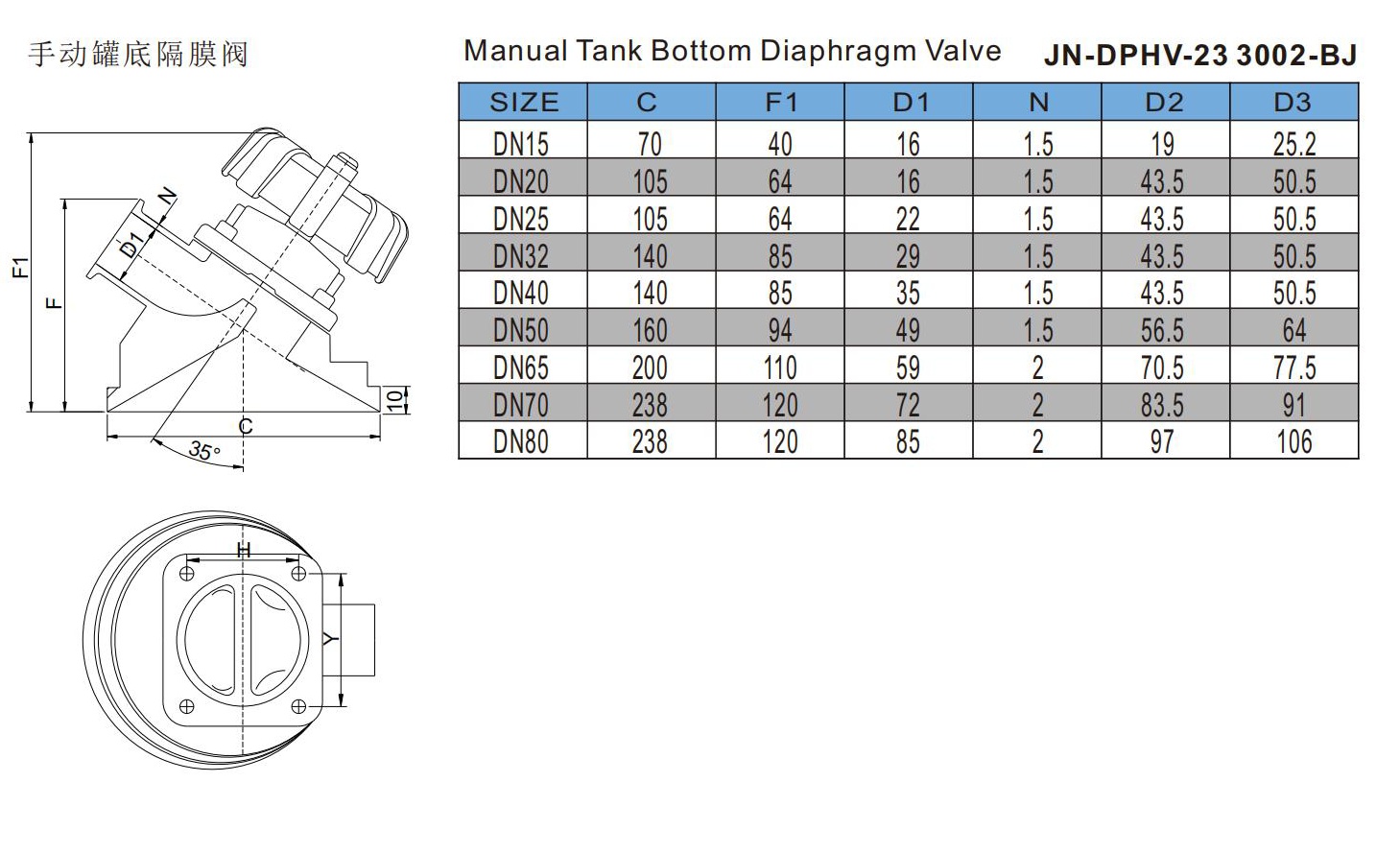

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

Features a Y-shaped flow channel that ensures smooth, efficient drainage and minimizes residual product inside tanks, reducing contamination risks.

Constructed from high-quality stainless steel with polished internal surfaces, providing excellent corrosion resistance and hygienic compliance.

DN80 ISO standard connection allows easy integration with various tank outlets and piping systems, ensuring secure and reliable installation.

Bottom-mounted design enables complete discharge by gravity, improving process efficiency and simplifying tank cleaning procedures.

Tight sealing mechanism guarantees leak-free performance, supporting repeated cleaning cycles and maintaining sterile conditions in sanitary applications

Application

Stainless Steel DN80 ISO Y Type Sanitary Tank Bottom Valves are commonly used in brewery and beverage production for draining wort, beer, or juices from fermentation and storage tanks. They are also applied in pharmaceutical and biotechnology industries, where sterile discharge of liquids is critical. Additionally, these valves are suitable for dairy and food processing, providing efficient tank emptying, minimal residue, and hygienic operation to maintain product quality and comply with strict sanitary regulations

Working Principles

The working principle of a Stainless Steel DN80 ISO Y Type Sanitary Tank Bottom Valve involves controlling the flow at the tank outlet using a Y-shaped flow channel. When the valve is opened manually or via an actuator, the valve plug lifts away from the seat, allowing liquid to discharge smoothly through the DN80 outlet. The Y-type design minimizes turbulence and promotes complete drainage by gravity, reducing residual product and preventing contamination. Closing the valve presses the plug firmly against the seat, ensuring a tight seal and preventing backflow. This valve is designed for hygienic applications, allowing easy cleaning and maintaining sterility in food, beverage, and pharmaceutical processes

Feature and Specification

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

Features a Y-shaped flow channel that ensures smooth, efficient drainage and minimizes residual product inside tanks, reducing contamination risks.

Constructed from high-quality stainless steel with polished internal surfaces, providing excellent corrosion resistance and hygienic compliance.

DN80 ISO standard connection allows easy integration with various tank outlets and piping systems, ensuring secure and reliable installation.

Bottom-mounted design enables complete discharge by gravity, improving process efficiency and simplifying tank cleaning procedures.

Tight sealing mechanism guarantees leak-free performance, supporting repeated cleaning cycles and maintaining sterile conditions in sanitary applications

Application

Stainless Steel DN80 ISO Y Type Sanitary Tank Bottom Valves are commonly used in brewery and beverage production for draining wort, beer, or juices from fermentation and storage tanks. They are also applied in pharmaceutical and biotechnology industries, where sterile discharge of liquids is critical. Additionally, these valves are suitable for dairy and food processing, providing efficient tank emptying, minimal residue, and hygienic operation to maintain product quality and comply with strict sanitary regulations