| Availability: | |

|---|---|

| Quantity: | |

JONENG

8421219990

Stainless Steel FDA Food Grade Manual Conical Tank Bottom Valve

The stainless steel sanitary manual tank bottom valve is designed to solve the challenge between high-precision liquid discharge and pipeline cleanliness, especially in the aseptic, food and pharmaceutical industries, to ensure that the liquid at the bottom of the tank can be completely and evenly discharged to prevent sediment or impurities from affecting product quality. It achieves precise emission control through manual operation, and adopts high-standard sanitary materials and designs to avoid cross contamination, support efficient CIP/SIP cleaning process, keep pipes and tanks clean, and ensure that fluids in the production process are not contaminated.

Working Principles

The working principle of the stainless steel sanitary manual tank bottom valve is to use a low-torque manual drive mechanism to drive the conical valve core up and down through a precision-machined valve stem to achieve precise fluid discharge. Its unique self-draining design can avoid residue at the bottom of the tank and prevent fluid retention from causing microbial growth. The special angle seal ensures no leakage when closed, while reducing fluid impact when opened, and avoiding foam or turbulence affecting product quality. Using a stainless steel sanitary manual tank bottom valve can achieve precise discharge, avoid microbial contamination caused by fluid retention, reduce cleaning difficulty, and improve production efficiency.

The options for stainless steel sanitary manual tank bottom valves include:

Valve body material: 304 stainless steel, 316L stainless steel

Seal material: EPDM, PTFE, silicone, Viton

Connection method: quick-install, welding, thread, flange

Valve core structure: conical, flat, with flushing port

Operation method: handwheel, pull rod, knob

Surface treatment: mirror polishing, electrolytic polishing

Discharge direction: straight discharge, L-type, U-type

Cleaning function: CIP/SIP compatible, removable cleaning interface

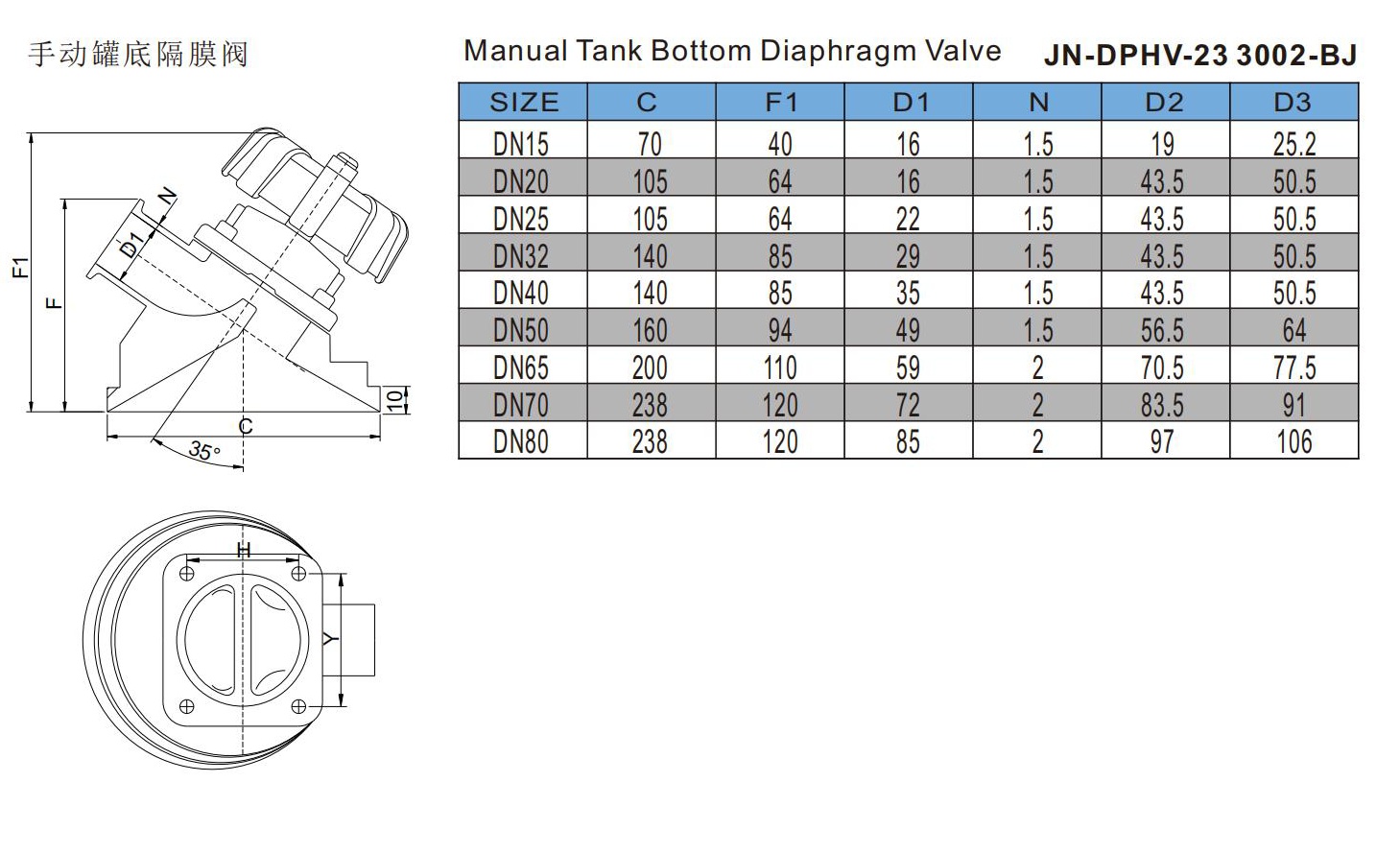

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● The stainless steel sanitary manual tank bottom valve core adopts a special angle cone design to ensure no residual liquid, reduce cross contamination, and meet CIP/SIP cleaning requirements.

● The stainless steel sanitary manual tank bottom valve adopts a seamless one-piece casting process, without welding points, to enhance pressure resistance, prevent bacterial growth, and improve the hygiene level.

● The tank bottom flow channel of the stainless steel sanitary manual tank bottom valve is optimized at a special angle to reduce dead angles and improve discharge efficiency.

● The stainless steel sanitary manual tank bottom valve adopts a mechanical limit design to prevent damage to the sealing ring due to excessive rotation, improve operational safety and service life.

● The inner wall of the stainless steel sanitary manual tank bottom valve body is finely polished to ≤0.4μm, reducing fluid residue and adhesion, and improving cleanliness and hygiene level.

● The stainless steel sanitary manual tank bottom valve has a reserved sensor installation interface, which can be connected to pressure, temperature or liquid level sensors to achieve intelligent monitoring and remote control.

Application

Stainless steel sanitary manual tank bottom valves are widely used in the following industries: Food and beverage industry: control the bottom discharge of storage tanks such as milk, juice, and beverages. Dairy industry: used for liquid discharge from the bottom of pasteurization tanks, fermentation tanks, etc. Pharmaceutical industry: used for liquid storage tanks to ensure aseptic discharge in accordance with GMP standards. Biotechnology industry: control the outflow of biological preparations such as vaccines and culture fluids from the bottom of tanks. Cosmetics industry: control the bottom discharge of storage tanks such as creams, essences, and perfumes. Drinking water treatment industry: used for pure water and ultrafiltration water tank bottom discharge and cleaning.

Working Principles

The working principle of the stainless steel sanitary manual tank bottom valve is to use a low-torque manual drive mechanism to drive the conical valve core up and down through a precision-machined valve stem to achieve precise fluid discharge. Its unique self-draining design can avoid residue at the bottom of the tank and prevent fluid retention from causing microbial growth. The special angle seal ensures no leakage when closed, while reducing fluid impact when opened, and avoiding foam or turbulence affecting product quality. Using a stainless steel sanitary manual tank bottom valve can achieve precise discharge, avoid microbial contamination caused by fluid retention, reduce cleaning difficulty, and improve production efficiency.

The options for stainless steel sanitary manual tank bottom valves include:

Valve body material: 304 stainless steel, 316L stainless steel

Seal material: EPDM, PTFE, silicone, Viton

Connection method: quick-install, welding, thread, flange

Valve core structure: conical, flat, with flushing port

Operation method: handwheel, pull rod, knob

Surface treatment: mirror polishing, electrolytic polishing

Discharge direction: straight discharge, L-type, U-type

Cleaning function: CIP/SIP compatible, removable cleaning interface

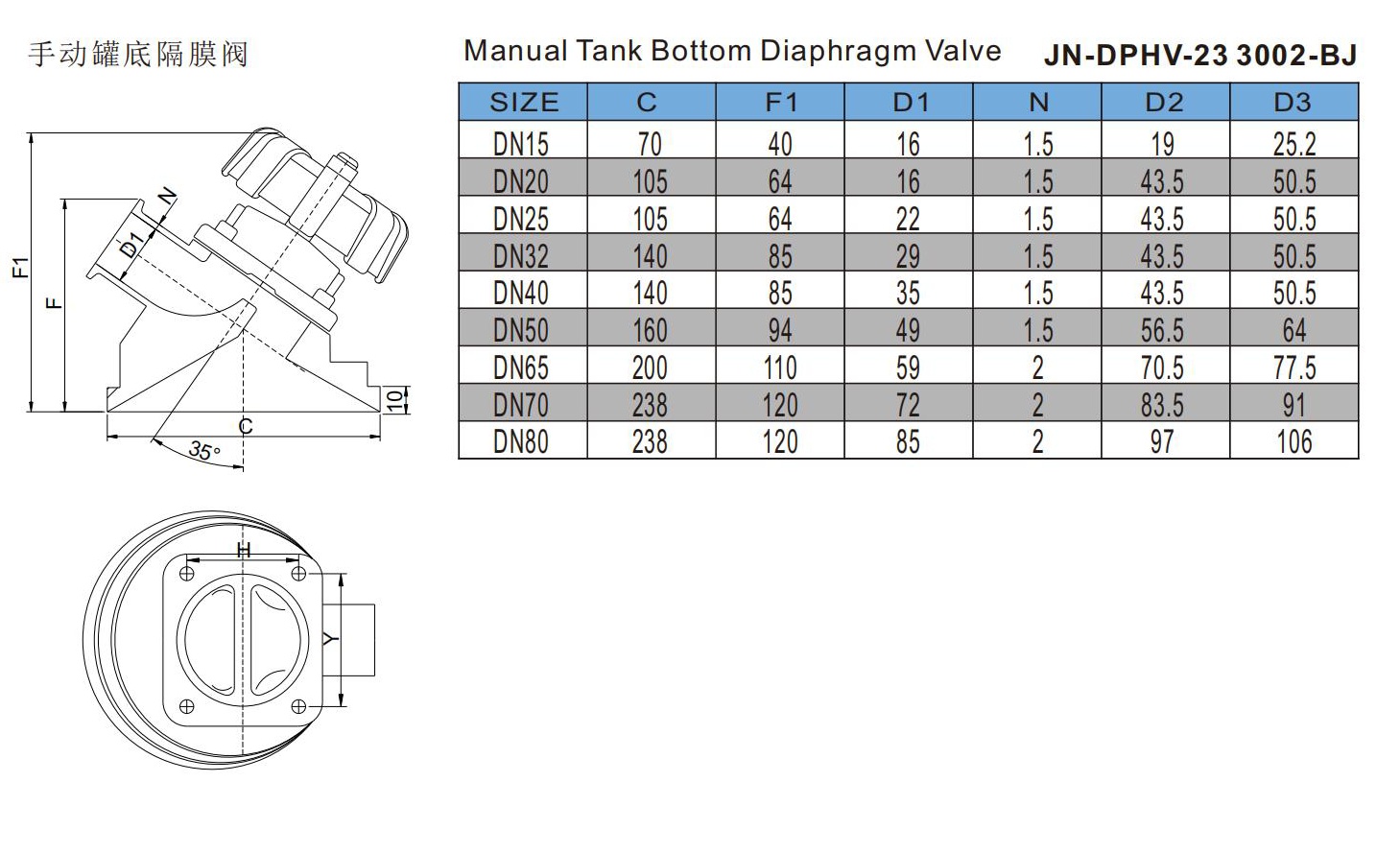

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● The stainless steel sanitary manual tank bottom valve core adopts a special angle cone design to ensure no residual liquid, reduce cross contamination, and meet CIP/SIP cleaning requirements.

● The stainless steel sanitary manual tank bottom valve adopts a seamless one-piece casting process, without welding points, to enhance pressure resistance, prevent bacterial growth, and improve the hygiene level.

● The tank bottom flow channel of the stainless steel sanitary manual tank bottom valve is optimized at a special angle to reduce dead angles and improve discharge efficiency.

● The stainless steel sanitary manual tank bottom valve adopts a mechanical limit design to prevent damage to the sealing ring due to excessive rotation, improve operational safety and service life.

● The inner wall of the stainless steel sanitary manual tank bottom valve body is finely polished to ≤0.4μm, reducing fluid residue and adhesion, and improving cleanliness and hygiene level.

● The stainless steel sanitary manual tank bottom valve has a reserved sensor installation interface, which can be connected to pressure, temperature or liquid level sensors to achieve intelligent monitoring and remote control.

Application

Stainless steel sanitary manual tank bottom valves are widely used in the following industries: Food and beverage industry: control the bottom discharge of storage tanks such as milk, juice, and beverages. Dairy industry: used for liquid discharge from the bottom of pasteurization tanks, fermentation tanks, etc. Pharmaceutical industry: used for liquid storage tanks to ensure aseptic discharge in accordance with GMP standards. Biotechnology industry: control the outflow of biological preparations such as vaccines and culture fluids from the bottom of tanks. Cosmetics industry: control the bottom discharge of storage tanks such as creams, essences, and perfumes. Drinking water treatment industry: used for pure water and ultrafiltration water tank bottom discharge and cleaning.