| Availability: | |

|---|---|

| Quantity: | |

The main components of an emulsifying pump are housing, rotor, stator, shaft, drive mechanism, bearing and seals. These components work in harmony to achieve efficient emulsification by creating intense shear forces that result in the formation of stable and uniform emulsions.

JONENG

8481804090

Stainless Steel Food Grade Bottom Mounted High Pressure Homogenizer

Stainless steel electric square high-pressure homogenizer ,This stainless steel electric square high-pressure homogenizer is engineered for fluid substances, featuring robust construction, corrosion resistance, and stable performance. Ideal for food, pharmaceutical, and chemical industries, it ensures uniform mixing and particle size reduction with easy operation and low maintenance.

Working Principles

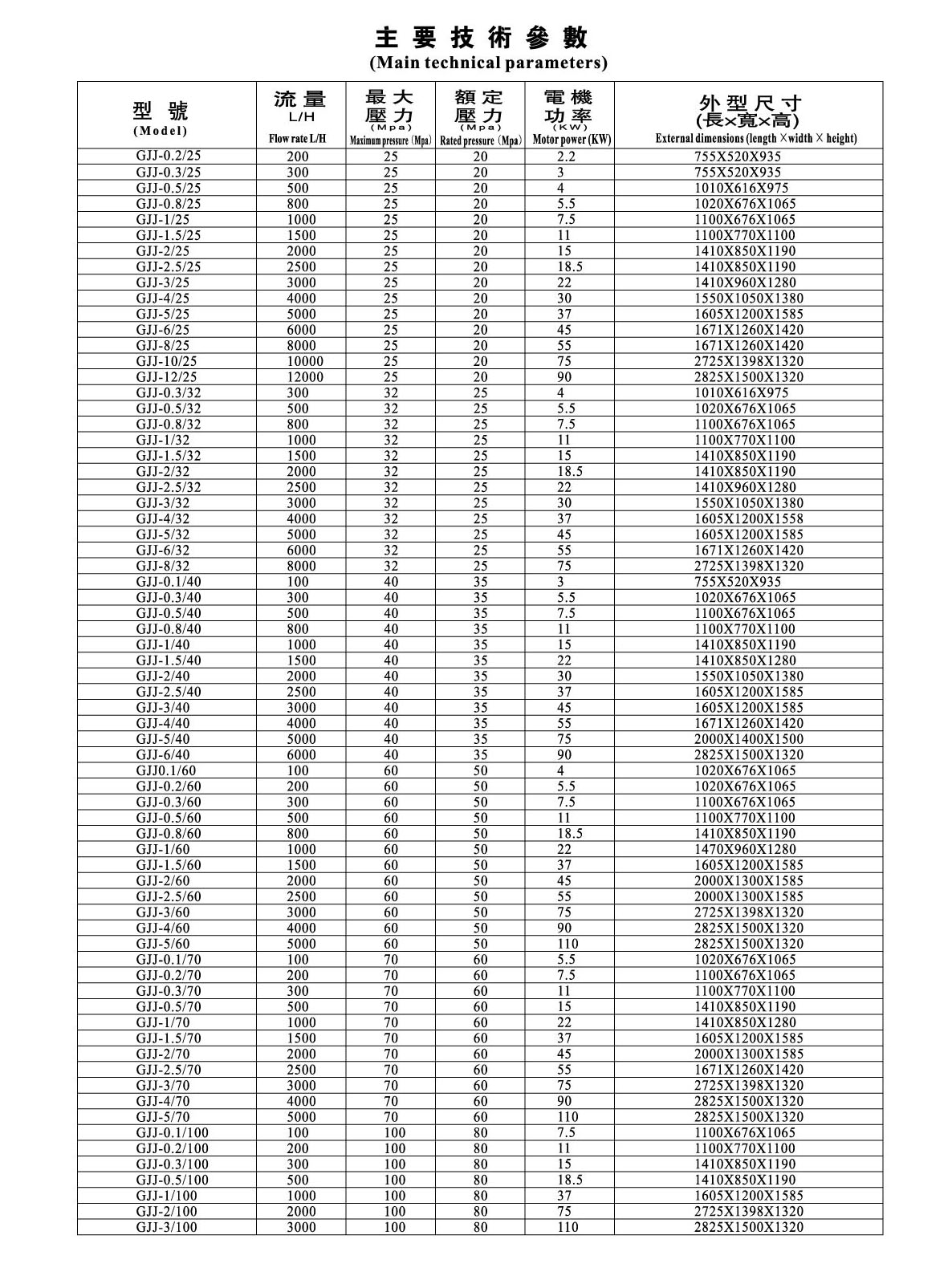

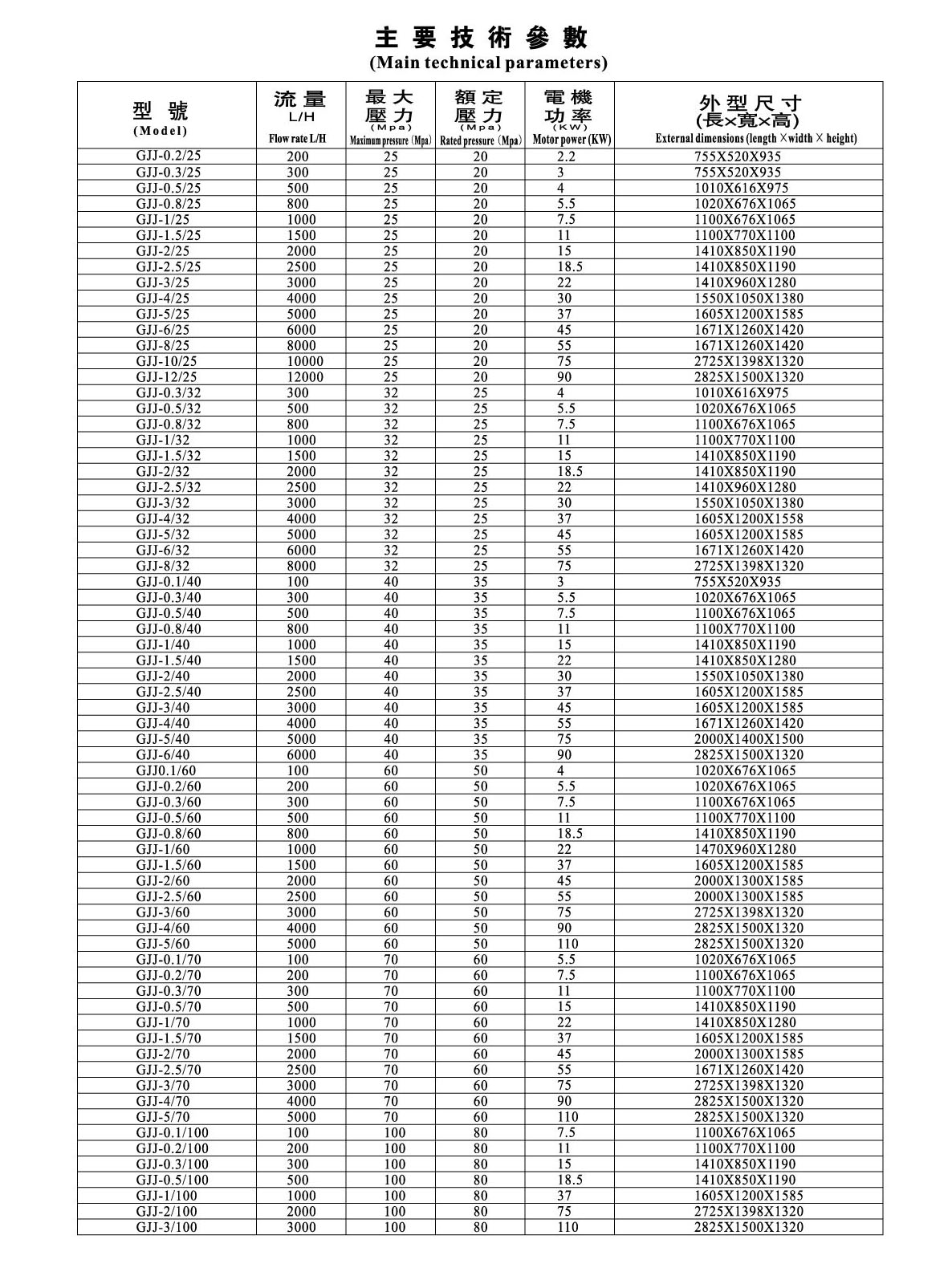

Stainless Steel Diaphragm Pump Specification Chart

Body material | AISI304/316L |

Mechanical seal | SiC/C/EPDM |

Gaskets | EPDM, PTFE |

Surface finish | Ra 0.8m |

Max. flow | 40m3/h |

Max. power | 45KW |

Max. temperatur | 140℃ |

Max. rex | 2900rpm |

Features

· Rotor-stator mechanism

· Adjustable shear forces

· Variable speed

· Ease of maintenance

· Compliance with standards

· Consistency in product quality

· Hygienic design for food and pharmaceutical application

· Adaptability to different viscosity

Application

The diaphragm pump is widely used in food industry, beverage industry, daily chemicals,medical industry, paper making industry and other higher sanitary requirements production.

Working Principles

Is typically installed inline within a milk or liquid processing pipeline, usually after pre-mixing and before final heating, filling, or packaging stages. At this position, it serves to refine and stabilize the emulsion by applying controlled high-shear forces directly to the flowing product. Its role is to eliminate agglomerates, reduce particle size, and ensure uniform distribution of fat and other components. Positioned inline, it supports continuous processing, minimizes manual handling, and helps maintain consistent product quality, hygiene, and process efficiency throughout the entire dairy production line.

Feature and Specification

Stainless Steel Self-Priming Pump Specification Chart

Max. flow rate | 50m3/h |

Frequency | 50HZ/60HZ |

Max. pressure | 8 bar |

Max. temperature | 110°C |

Material | SS304/SS316L |

| Inlet/outlet connection | Clamp, Weld, Flange |

| Inlet/outlet size | 1”-3” |

| Diaphragm | PTFE, PTFE with white back, EPDM, white EPDM, white NBR |

| Driving way | Air or Motor |

Features

●The pump is designed for cleaning and sterilization in place-C.I.P. and S.I.P

● It is easy to connect because of quick assemble tri-clamp

● Wide range of diaphragm materials area available

● It is suited for transferring viscous and shear sensitive products

● The smooth design of this diaphragm eliminate potential contaminant risk

● It can accept dry run conditions

Application

The diaphragm pump is widely used in food industry, beverage industry, daily chemicals,medical industry, paper making industry and other higher sanitary requirements production.