| Availability: | |

|---|---|

| Quantity: | |

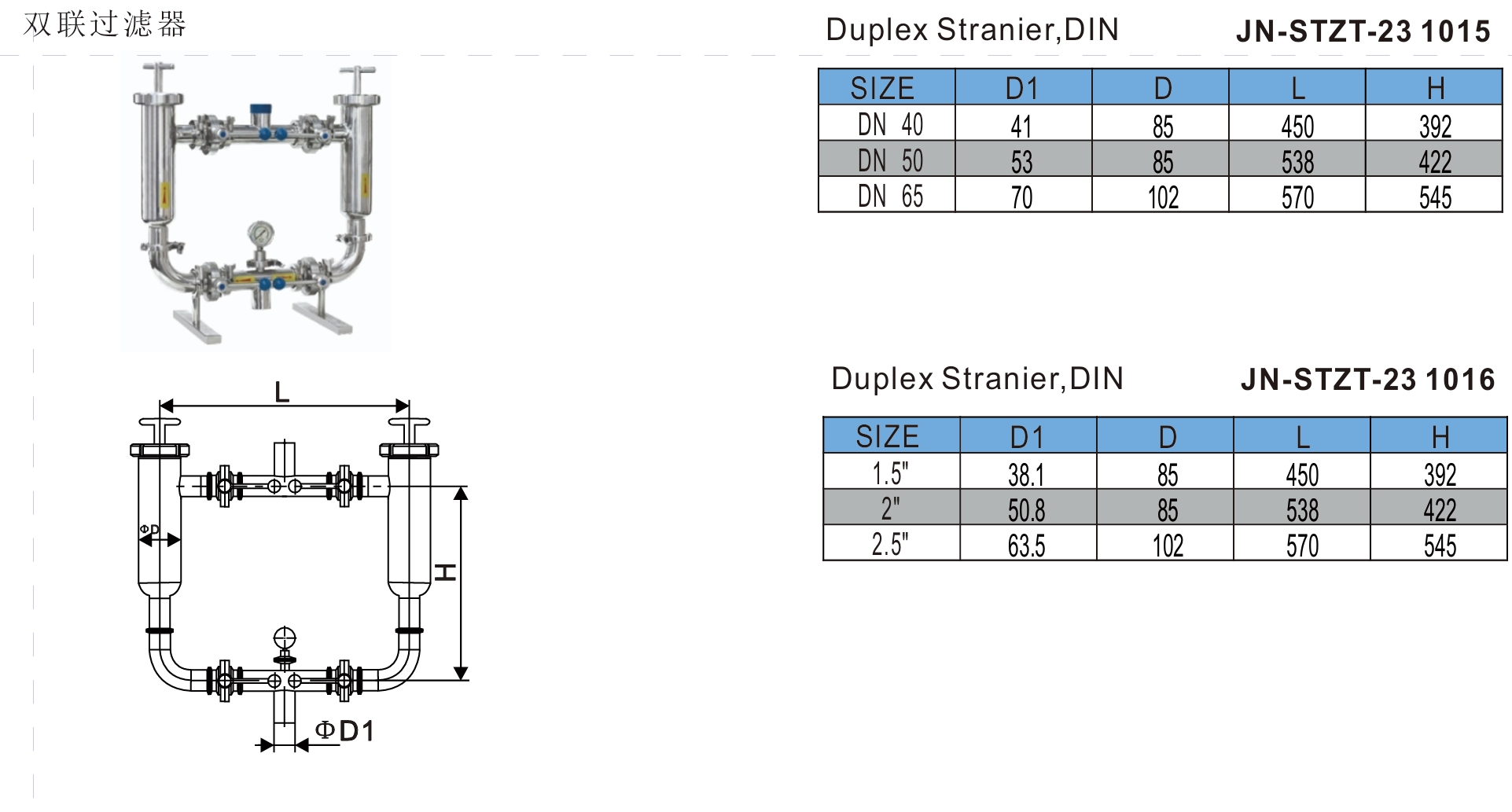

The stainless steel sanitary duplex filter is a device for fluid filtration. It is designed with two parallel filter units to ensure that the liquid in the system can always remain clean during the flow process. Its main use is in the food, beverage, pharmaceutical and other industries. The stainless steel sanitary duplex filter is usually installed at the entrance of the liquid delivery pipeline or the front end of the production line. It is used to filter impurities in the liquid for the first time and protect subsequent equipment. It can also be installed in the circulation pipeline. Common types of stainless steel sanitary duplex filters include: Y-type duplex filter, T-type duplex filter, cartridge duplex filter, bag duplex filter, and rotary duplex filter.

JONENG

8421219990

Stainless Steel Quick Installation Sanitary Duplex Filter Housing

The stainless steel sanitary duplex filter is designed to ensure continuous fluid filtration in an environment that requires high hygiene standards. Through the duplex structure, the system can alternately use two filter units without stopping production. In this way, when one filter unit needs to be cleaned or the filter element needs to be replaced, the other filter unit still keeps working, avoiding production interruptions. This design improves the reliability and maintenance efficiency of the equipment. It is particularly suitable for industries with extremely high hygiene requirements such as food, beverages, and pharmaceuticals, ensuring the purity and quality consistency of the product.

Working Principles

The working principle of the stainless steel sanitary duplex filter is based on a duplex design, and each filter unit is equipped with an independent filter element. When the liquid flows into the filter, it first enters the filter element of one filter unit, and the solid impurities are filtered out through the physical action of the filter element. The filtered liquid flows to the downstream system. During operation, when one filter unit needs to be cleaned or the filter element replaced, the other filter unit automatically starts working to ensure that the system will not shut down. The whole process is uninterrupted, and by switching the filter unit, the continuous filtering effect and stable operation of the system are guaranteed.

Common options for stainless steel sanitary duplex filters include:

Filter element material: stainless steel 304, 316L, etc., adapted to different media.

Filter element pore size: selected according to the filtration accuracy requirements, commonly 10μm, 20μm, etc.

Connection method: quick-install, flange, threaded, etc.

Cleaning method: manual cleaning, automatic backwashing function.

Working pressure: different working pressures can be customized according to the use requirements.

Sealing material: different high temperature resistant and corrosion resistant sealing materials can be selected.

Installation method: horizontal installation, vertical installation.

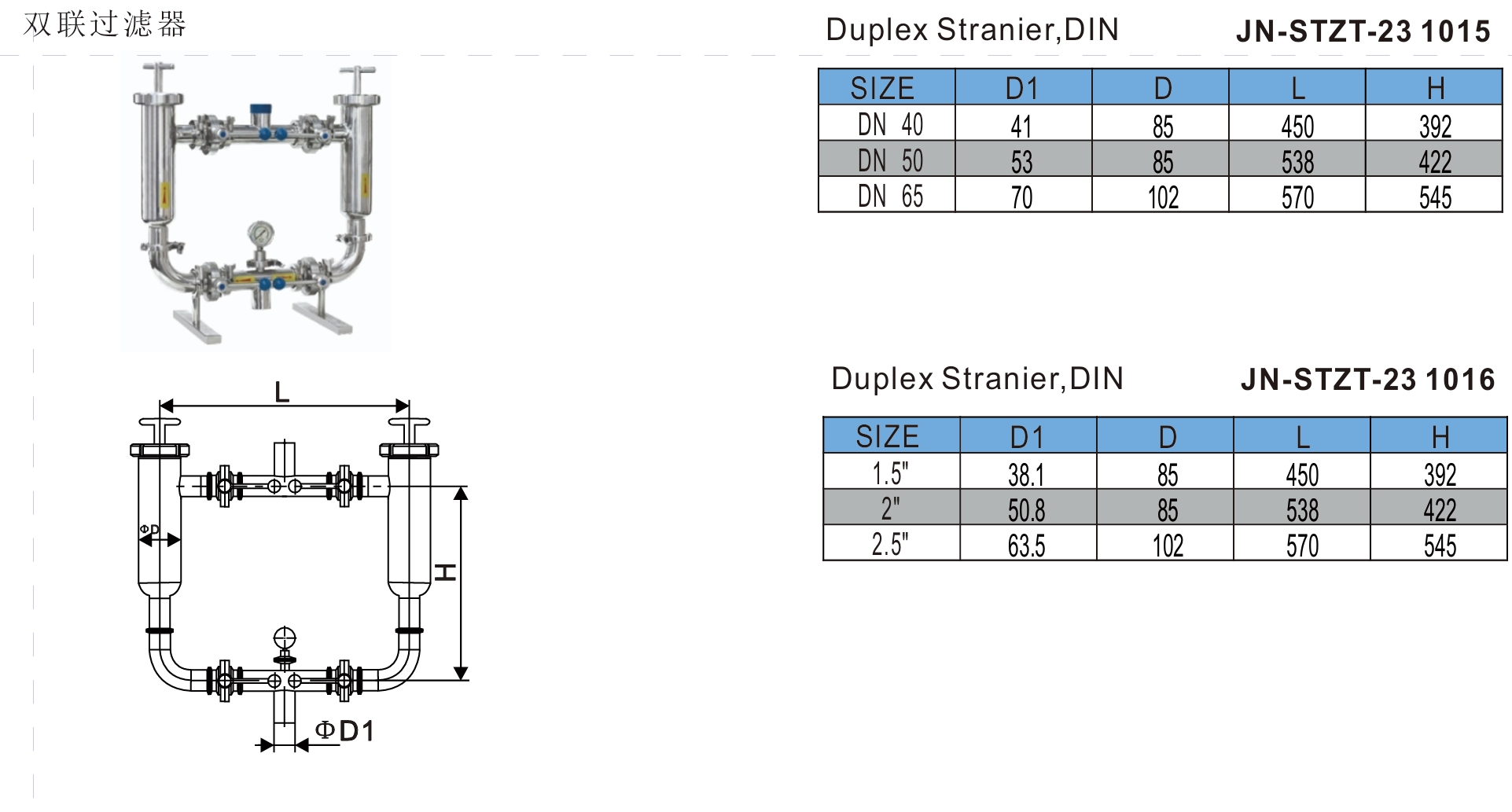

Specification Chart

Material | SS304, SS316L |

Size | 1”-4” |

Inner surface finish | Ra0.5 |

External surface finish | Ra 0.8 |

Standard | SMS, 3A, BPE, ISO |

Seals | EPDM, PTFE, Silicone |

Max pressure | 10 bar |

Max temperature | -10℃ to 120℃ |

| End connection | Threaded, welded, clamped |

| Screen | 30-300 meshes |

| Screen hole | 0.5mm-2mm |

Features

● The stainless steel sanitary duplex filter is designed with an intelligent flow balancing system, which automatically adjusts the working ratio of the two units through the flow sensor to ensure balanced filtering load.

● The stainless steel sanitary duplex filter adopts a built-in self-cleaning device. When the filter element or filter unit is blocked, the cleaning mode is automatically started to remove sediment.

● The stainless steel sanitary duplex filter uses low-temperature resistant materials and special seals to meet the filtering requirements of low-temperature or refrigerated liquids.

● The stainless steel sanitary duplex filter adopts a patented anti-corrosion coating and an improved filter element design to effectively prevent chemical reactions or scaling during the filtration process.

● The unique fluid path optimization design of the stainless steel sanitary duplex filter significantly reduces the pressure drop of the filter, minimizing the energy loss during the filtration process.

● The stainless steel sanitary duplex filter adopts high-temperature isolation technology, which can effectively isolate high-temperature liquids from the external environment and avoid the influence of temperature fluctuations on the filtering effect.

Application

Stainless steel sanitary duplex filters are widely used in the following industries: Food processing industry: used to remove impurities in liquid food to ensure product hygiene. Pharmaceutical industry: filter liquid medicine to keep it sterile and meet pharmaceutical production standards. Dairy industry: filter dairy products to prevent bacterial contamination and ensure stable quality. Beverage industry: ensure the cleanliness and hygiene of liquids during beverage production. Chemical industry: used for precise filtration of chemical liquids and protection of production equipment.

Working Principles

The working principle of the stainless steel sanitary duplex filter is based on a duplex design, and each filter unit is equipped with an independent filter element. When the liquid flows into the filter, it first enters the filter element of one filter unit, and the solid impurities are filtered out through the physical action of the filter element. The filtered liquid flows to the downstream system. During operation, when one filter unit needs to be cleaned or the filter element replaced, the other filter unit automatically starts working to ensure that the system will not shut down. The whole process is uninterrupted, and by switching the filter unit, the continuous filtering effect and stable operation of the system are guaranteed.

Common options for stainless steel sanitary duplex filters include:

Filter element material: stainless steel 304, 316L, etc., adapted to different media.

Filter element pore size: selected according to the filtration accuracy requirements, commonly 10μm, 20μm, etc.

Connection method: quick-install, flange, threaded, etc.

Cleaning method: manual cleaning, automatic backwashing function.

Working pressure: different working pressures can be customized according to the use requirements.

Sealing material: different high temperature resistant and corrosion resistant sealing materials can be selected.

Installation method: horizontal installation, vertical installation.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary duplex filter is designed with an intelligent flow balancing system, which automatically adjusts the working ratio of the two units through the flow sensor to ensure balanced filtering load.

● The stainless steel sanitary duplex filter adopts a built-in self-cleaning device. When the filter element or filter unit is blocked, the cleaning mode is automatically started to remove sediment.

● The stainless steel sanitary duplex filter uses low-temperature resistant materials and special seals to meet the filtering requirements of low-temperature or refrigerated liquids.

● The stainless steel sanitary duplex filter adopts a patented anti-corrosion coating and an improved filter element design to effectively prevent chemical reactions or scaling during the filtration process.

● The unique fluid path optimization design of the stainless steel sanitary duplex filter significantly reduces the pressure drop of the filter, minimizing the energy loss during the filtration process.

● The stainless steel sanitary duplex filter adopts high-temperature isolation technology, which can effectively isolate high-temperature liquids from the external environment and avoid the influence of temperature fluctuations on the filtering effect.

Application

Stainless steel sanitary duplex filters are widely used in the following industries: Food processing industry: used to remove impurities in liquid food to ensure product hygiene. Pharmaceutical industry: filter liquid medicine to keep it sterile and meet pharmaceutical production standards. Dairy industry: filter dairy products to prevent bacterial contamination and ensure stable quality. Beverage industry: ensure the cleanliness and hygiene of liquids during beverage production. Chemical industry: used for precise filtration of chemical liquids and protection of production equipment.