| Availability: | |

|---|---|

| Quantity: | |

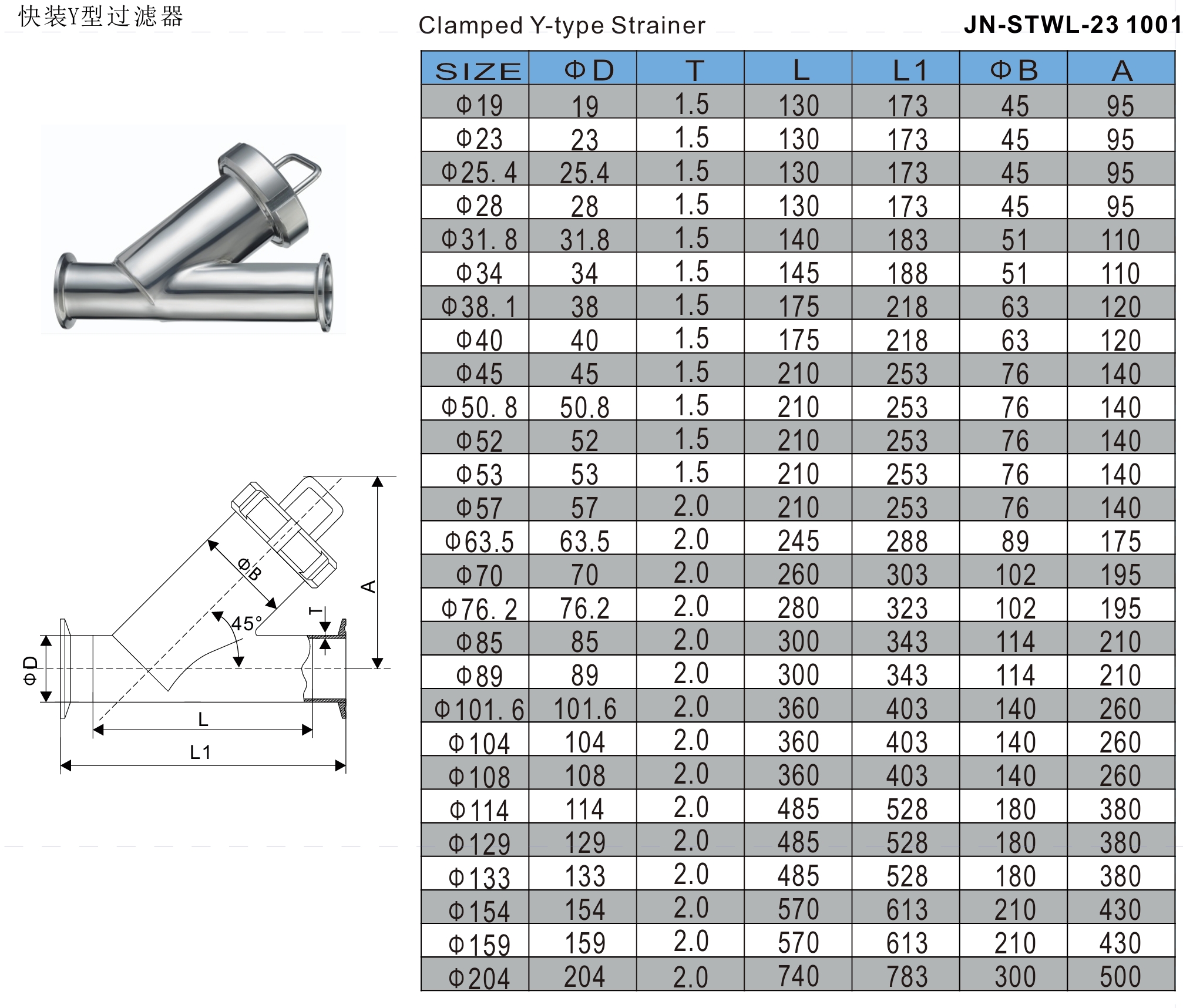

The stainless steel sanitary Y-type filter is a filtering device designed for fluid pipeline systems. It is mainly used to filter impurities, solid particles, sand, etc. in the fluid to ensure that downstream equipment (such as pumps, valves, instruments, etc.) is protected from damage and blockage, and to maintain the cleanliness and stability of the system. Its "Y"-shaped structure facilitates the increase of the filtration area and ensures smooth fluid flow, ensuring the normal operation of pipelines and equipment.

The stainless steel sanitary Y-type filter is widely used in liquid or gas pipelines in food, beverage, pharmaceutical, chemical, refrigeration, air conditioning, water supply and other industries. It is generally installed at the inlet or outlet of the pipeline to filter impurities in the pipeline.

The types of stainless steel sanitary Y-type filters include: coarse filtration, medium filtration, and fine filtration according to filtration accuracy; manual cleaning and automatic cleaning according to cleaning methods; 304 and 316L stainless steel according to materials; threaded and flanged connections according to connection methods; standard type and type with observation window and drain port according to design.

JN-STWL-23 1001

JONENG

8421219990

Stainless Steel High Performance Multicartridge Y-thread Bag Filter

The stainless steel sanitary Y-type filter is designed to intercept impurities through a precise filter mesh, protect pumps, valves and other equipment from damage, reduce equipment failures and maintenance costs, and ensure the cleanliness of the fluid and the normal operation of the system. The filter meets sanitary standards and is commonly used in industries such as food, beverages, and pharmaceuticals that require high cleanliness to ensure product quality and safety in the production process.

Working Principles

The working principle of the stainless steel sanitary Y-type filter is that the fluid enters through the filter inlet and impurities are intercepted by the stainless steel mesh filter. The purified fluid is discharged from the outlet. As impurities accumulate, the filter can be cleaned manually or automatically to ensure continuous purification of the fluid and protect the pipeline and equipment.

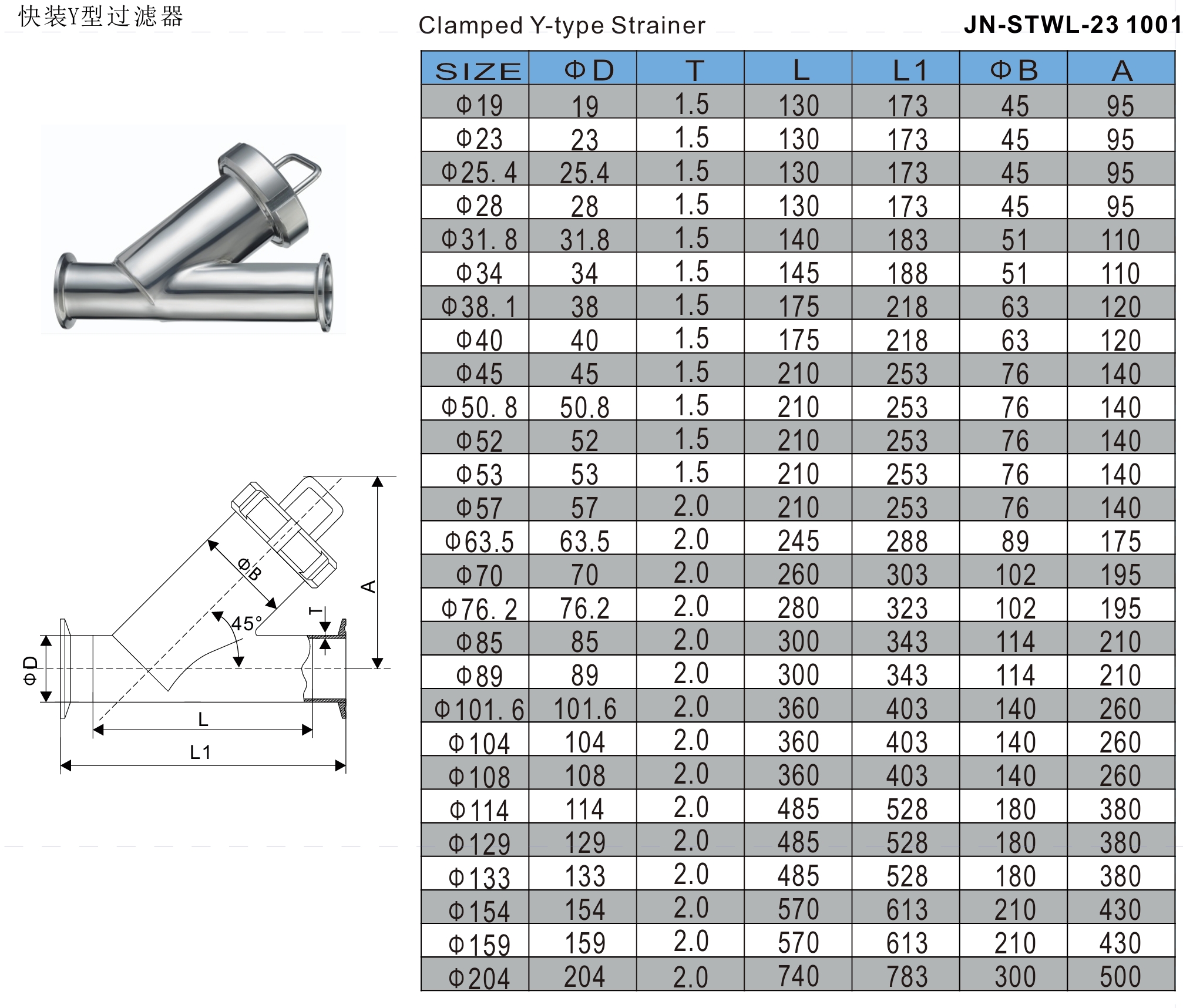

Specification Chart

Size | 1”-4” |

Material | AISI 316, AISI 304 |

Connection | Clamped, Welded, Threaded |

Gasket | Silicone, EPDM, Viton, PTFE |

Standard | 3A, DIN, SMS, ISO |

Mesh size | From 0.5mm to 2.0mm |

Screen | From 30 mesh to 300 mesh |

Internal Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

| External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The stainless steel sanitary Y-type filter is made of 304 or 316L stainless steel material, which has excellent corrosion resistance and oxidation resistance and can be used for a long time in harsh working environments.

● The stainless steel sanitary Y-type filter is designed as a Y-type filter with a larger internal space and a larger filter area.

● The stainless steel sanitary Y-type filter adopts threaded connection, which is convenient for quick docking with the pipeline system.

● The stainless steel sanitary Y-type filter has a built-in high-precision filter (such as 100-200 mesh), which can effectively remove impurities and solid particles in the pipeline.

● The stainless steel sanitary Y-type filter has a compact design and occupies a small space.

● The stainless steel sanitary Y-type filter uses high-quality sealing materials (such as PTFE) to ensure the sealing of the connection.

Application

Stainless steel sanitary Y-type filters are widely used in the following industry fields: Food and beverage industry: filter impurities in liquids to ensure product quality. Pharmaceutical industry: used for cleaning fluids to ensure the purity of the drug production process. Biological products industry: used for filtering biological products to prevent pollution. Chemical industry: filter chemicals to protect equipment from damage by solid impurities. Water treatment industry: used for water quality filtration to ensure the normal operation of water treatment systems. Cosmetics industry: ensuring fluid cleanliness during the cosmetics production process.

Working Principles

The working principle of the stainless steel sanitary Y-type filter is that the fluid enters through the filter inlet and impurities are intercepted by the stainless steel mesh filter. The purified fluid is discharged from the outlet. As impurities accumulate, the filter can be cleaned manually or automatically to ensure continuous purification of the fluid and protect the pipeline and equipment.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary Y-type filter is made of 304 or 316L stainless steel material, which has excellent corrosion resistance and oxidation resistance and can be used for a long time in harsh working environments.

● The stainless steel sanitary Y-type filter is designed as a Y-type filter with a larger internal space and a larger filter area.

● The stainless steel sanitary Y-type filter adopts threaded connection, which is convenient for quick docking with the pipeline system.

● The stainless steel sanitary Y-type filter has a built-in high-precision filter (such as 100-200 mesh), which can effectively remove impurities and solid particles in the pipeline.

● The stainless steel sanitary Y-type filter has a compact design and occupies a small space.

● The stainless steel sanitary Y-type filter uses high-quality sealing materials (such as PTFE) to ensure the sealing of the connection.

Application

Stainless steel sanitary Y-type filters are widely used in the following industry fields: Food and beverage industry: filter impurities in liquids to ensure product quality. Pharmaceutical industry: used for cleaning fluids to ensure the purity of the drug production process. Biological products industry: used for filtering biological products to prevent pollution. Chemical industry: filter chemicals to protect equipment from damage by solid impurities. Water treatment industry: used for water quality filtration to ensure the normal operation of water treatment systems. Cosmetics industry: ensuring fluid cleanliness during the cosmetics production process.