| Availability: | |

|---|---|

| Quantity: | |

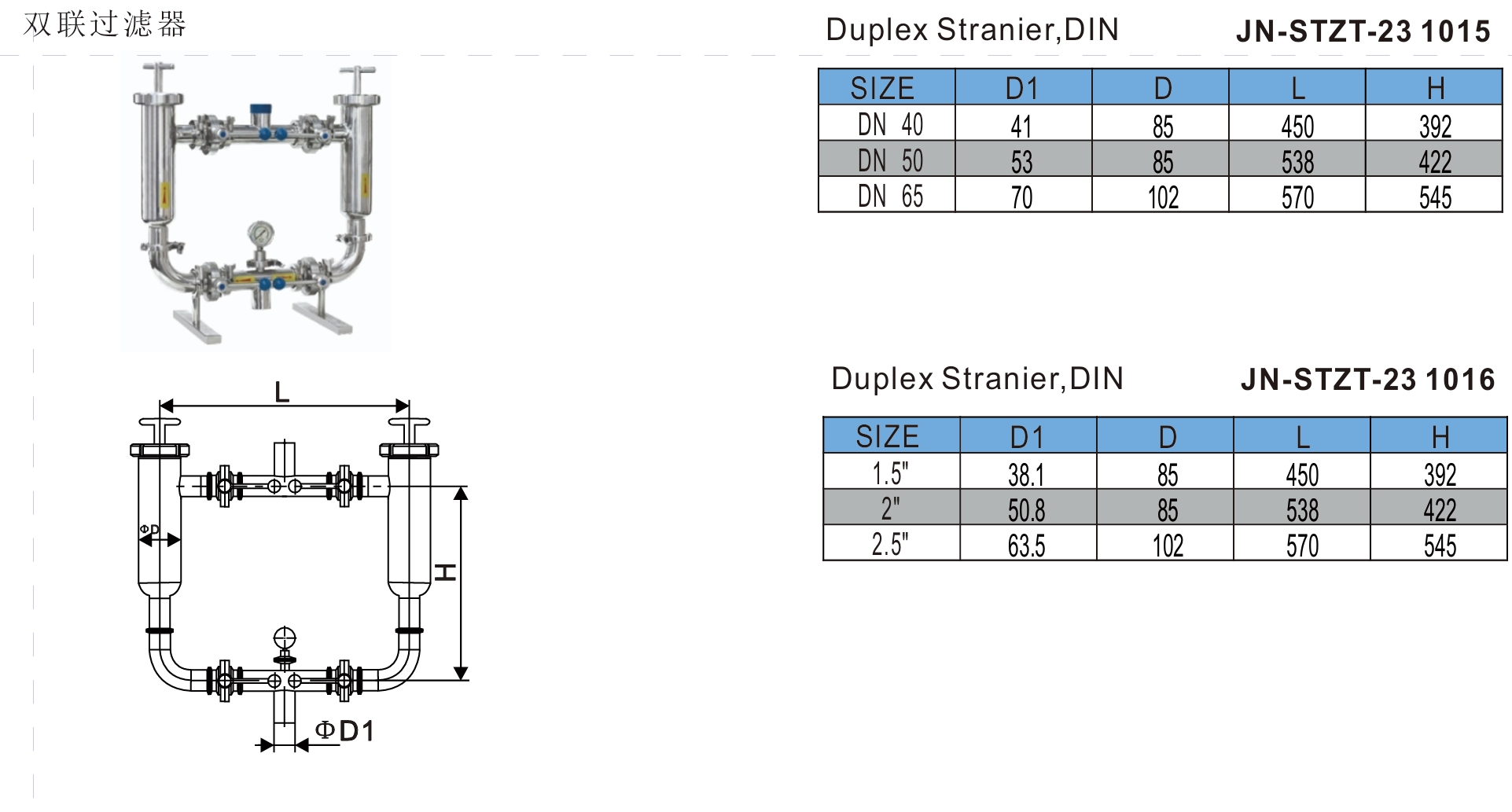

The stainless steel sanitary duplex filter is a high-efficiency filtration equipment that provides continuous operation and efficient impurity removal. The duplex filter can be used in fields such as ultrapure water treatment, cosmetic raw material filtration, and particle filtration in liquid emulsification. It is particularly suitable for liquid filtration that requires extremely high cleanliness to avoid pollutants interfering with key production processes. The stainless steel sanitary duplex bag filter is usually used in liquid delivery pipelines in the food, pharmaceutical, chemical and other industries, and is installed at the inlet and outlet of the pipeline. Common types of stainless steel sanitary duplex filters include: standard duplex filter, automatic backwash duplex filter, high-flow duplex filter, multi-stage duplex filter, and heated duplex filter.

JONENG

8421219990

Stainless Steel High Performance Thread Duplex Bag Filter for Pressure Gauge

The core purpose of the stainless steel sanitary duplex filter design is to ensure that during the high-precision liquid filtration process, when one filter bag is maintained or replaced, the other filter bag continues to work to avoid production interruptions. Its unique duplex structure, in addition to the common impurity removal function, can also optimize the load balance of the liquid handling system and avoid reduced filtration efficiency when filtering high-flow, high-viscosity or gas-containing liquids. In addition, its sealing design can prevent the penetration of trace pollutants, which is particularly suitable for special industries that require strict control of impurity content, such as high-end chemicals, medical equipment manufacturing, and aerospace material processing.

Working Principles

The working principle of the stainless steel sanitary duplex filter is based on the rotation of two sets of filter bag systems. The liquid first enters the first filter bag unit through the inlet of the filter, and the filter medium in the filter bag captures impurities and particles in the liquid. As the filter bag gradually accumulates impurities, the differential pressure sensor in the system will monitor the change in pressure difference, indicating that the filter bag needs to be replaced or cleaned. At this time, the other filter bag unit is started, and the liquid flows through the second filter bag for filtration. The duplex structure allows one unit to continue working while the other unit is maintained, avoiding interruptions in the production process.

The options of the stainless steel sanitary duplex filter include:

Filter bag material: polyester, polypropylene, nylon, etc.

Filter bag pore size: different pore sizes to meet different filtration accuracy requirements.

Automatic backwashing function: reduce the frequency of manual cleaning.

Differential pressure monitoring system: real-time monitoring of filtration status.

Drainage method: manual or automatic drainage.

Heating function: suitable for high-temperature liquid filtration.

Connection methods: welding, quick release, thread, etc.

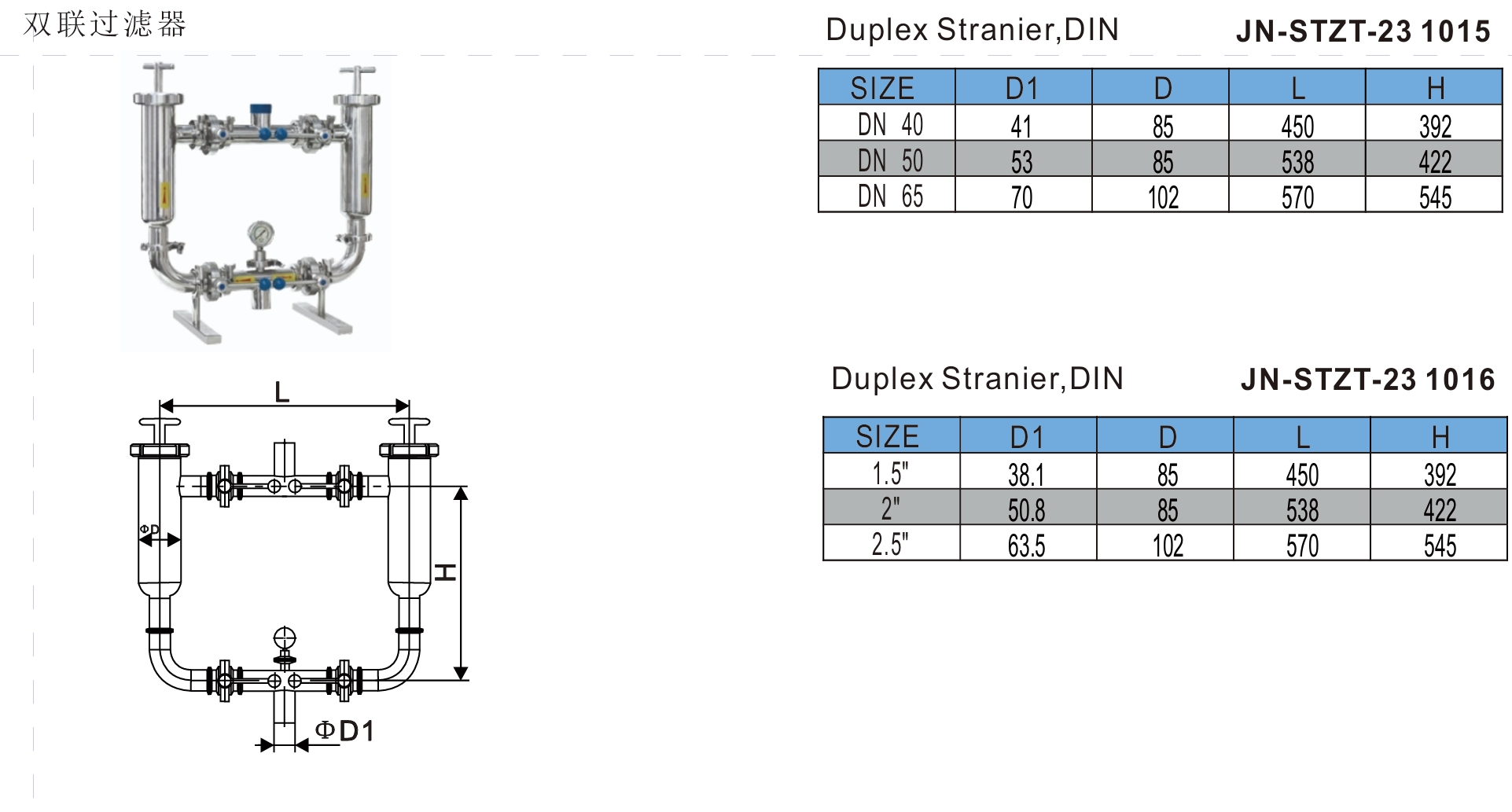

Specification Chart

Material | SS304, SS316L |

Size | 1”-4” |

Inner surface finish | Ra0.5 |

External surface finish | Ra 0.8 |

Standard | SMS, 3A, BPE, ISO |

Seals | EPDM, PTFE, Silicone |

Max pressure | 10 bar |

Max temperature | -10℃ to 120℃ |

| End connection | Threaded, welded, clamped |

| Screen | 30-300 meshes |

| Screen hole | 0.5mm-2mm |

Features

● The stainless steel sanitary duplex filter uses adaptive tension control technology to adjust the tension of the filter bag to ensure that the best filtering effect is always maintained under different flow rates and working pressures.

● The stainless steel sanitary duplex filter has a built-in high-precision differential pressure sensor to monitor the pressure difference between the filter inlet and outlet in real time, and automatically alarm when the differential pressure exceeds the preset value.

● The stainless steel sanitary duplex filter adopts a locking buckle structure to ensure that the filter bag will not shift or deform under high pressure and enhance the sealing performance.

● The stainless steel sanitary duplex filter is equipped with a double-layer filter screen structure, the outer layer is a coarse filter screen, and the inner layer is a fine filter screen, providing multi-stage filtration.

● The filter bag of the stainless steel sanitary duplex filter adopts an automatic opening device, which automatically stretches when bagging to ensure uniform force on the bag body.

● The stainless steel sanitary duplex filter has an adjustable sewage outlet, which is convenient for adjusting the sewage discharge speed and flow according to different working conditions and optimizing sewage discharge.

Application

Stainless steel sanitary duplex filters are used in the following industries: Food industry: remove impurities in liquids to ensure clean food production. Pharmaceutical industry: filter impurities in the production process of drugs to ensure the purity of drugs. Beverage industry: filter raw material liquids to ensure beverage quality and safety. Cosmetics industry: filter raw materials for cosmetics production to avoid impurity pollution. Water treatment industry: efficiently filter suspended matter in water to ensure water quality. Petrochemical industry: remove solid impurities from chemical liquids and protect equipment.

Working Principles

The working principle of the stainless steel sanitary duplex filter is based on the rotation of two sets of filter bag systems. The liquid first enters the first filter bag unit through the inlet of the filter, and the filter medium in the filter bag captures impurities and particles in the liquid. As the filter bag gradually accumulates impurities, the differential pressure sensor in the system will monitor the change in pressure difference, indicating that the filter bag needs to be replaced or cleaned. At this time, the other filter bag unit is started, and the liquid flows through the second filter bag for filtration. The duplex structure allows one unit to continue working while the other unit is maintained, avoiding interruptions in the production process.

The options of the stainless steel sanitary duplex filter include:

Filter bag material: polyester, polypropylene, nylon, etc.

Filter bag pore size: different pore sizes to meet different filtration accuracy requirements.

Automatic backwashing function: reduce the frequency of manual cleaning.

Differential pressure monitoring system: real-time monitoring of filtration status.

Drainage method: manual or automatic drainage.

Heating function: suitable for high-temperature liquid filtration.

Connection methods: welding, quick release, thread, etc.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary duplex filter uses adaptive tension control technology to adjust the tension of the filter bag to ensure that the best filtering effect is always maintained under different flow rates and working pressures.

● The stainless steel sanitary duplex filter has a built-in high-precision differential pressure sensor to monitor the pressure difference between the filter inlet and outlet in real time, and automatically alarm when the differential pressure exceeds the preset value.

● The stainless steel sanitary duplex filter adopts a locking buckle structure to ensure that the filter bag will not shift or deform under high pressure and enhance the sealing performance.

● The stainless steel sanitary duplex filter is equipped with a double-layer filter screen structure, the outer layer is a coarse filter screen, and the inner layer is a fine filter screen, providing multi-stage filtration.

● The filter bag of the stainless steel sanitary duplex filter adopts an automatic opening device, which automatically stretches when bagging to ensure uniform force on the bag body.

● The stainless steel sanitary duplex filter has an adjustable sewage outlet, which is convenient for adjusting the sewage discharge speed and flow according to different working conditions and optimizing sewage discharge.

Application

Stainless steel sanitary duplex filters are used in the following industries: Food industry: remove impurities in liquids to ensure clean food production. Pharmaceutical industry: filter impurities in the production process of drugs to ensure the purity of drugs. Beverage industry: filter raw material liquids to ensure beverage quality and safety. Cosmetics industry: filter raw materials for cosmetics production to avoid impurity pollution. Water treatment industry: efficiently filter suspended matter in water to ensure water quality. Petrochemical industry: remove solid impurities from chemical liquids and protect equipment.