| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

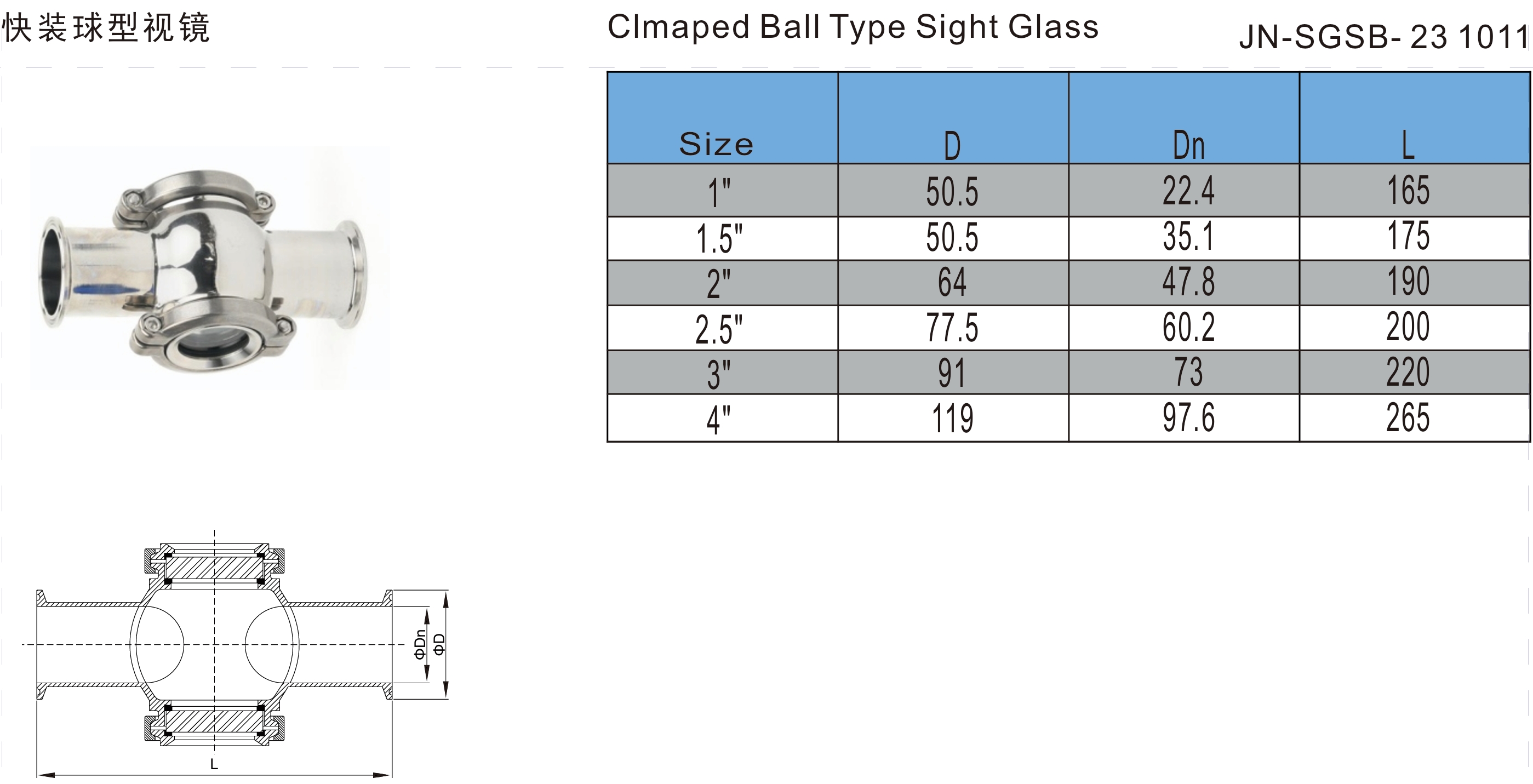

Stainless Steel Hygienic PTFE Four-way Spherical Through Window Sight Glass

The stainless steel sanitary four-way spherical sight glass is designed to provide a 360° clear visual window, which is convenient for operators to observe the flow, color, foam or impurities of the medium to ensure the stability of the production process and product quality. At the same time, the sight glass has a four-way structure, which allows fluids to flow in multiple directions, improving the flexibility and efficiency of the pipeline system. The use of sanitary stainless steel and high-temperature and high-pressure resistant glass ensures that the equipment is durable and easy to clean, meets strict hygiene standards, and meets the requirements of a sterile production environment.

Working Principles

The working principle of the stainless steel sanitary four-way spherical sight glass is to provide 360°all-round visualization through a transparent spherical glass window, allowing operators to directly observe the flow state, color, bubbles or impurities of the fluid in the pipeline. The use of the stainless steel sanitary four-way spherical sight glass can monitor the flow and residue of the cleaning fluid in real time to ensure thorough cleaning and reduce the waste of water and chemical cleaning agents.

The options of the stainless steel sanitary four-way spherical sight glass include:

Material selection: 304, 316L stainless steel

Glass type: tempered glass, high temperature and high pressure resistant glass

Connection method: quick installation, welding, thread, flange

Sealing material: EPDM, PTFE, silicone, Viton

Surface treatment: mirror polishing, electrolytic polishing, sandblasting

Working pressure level: normal pressure, high pressure tolerance type

Additional functions: LED lighting, heating jacket, pressure/temperature sensor interface

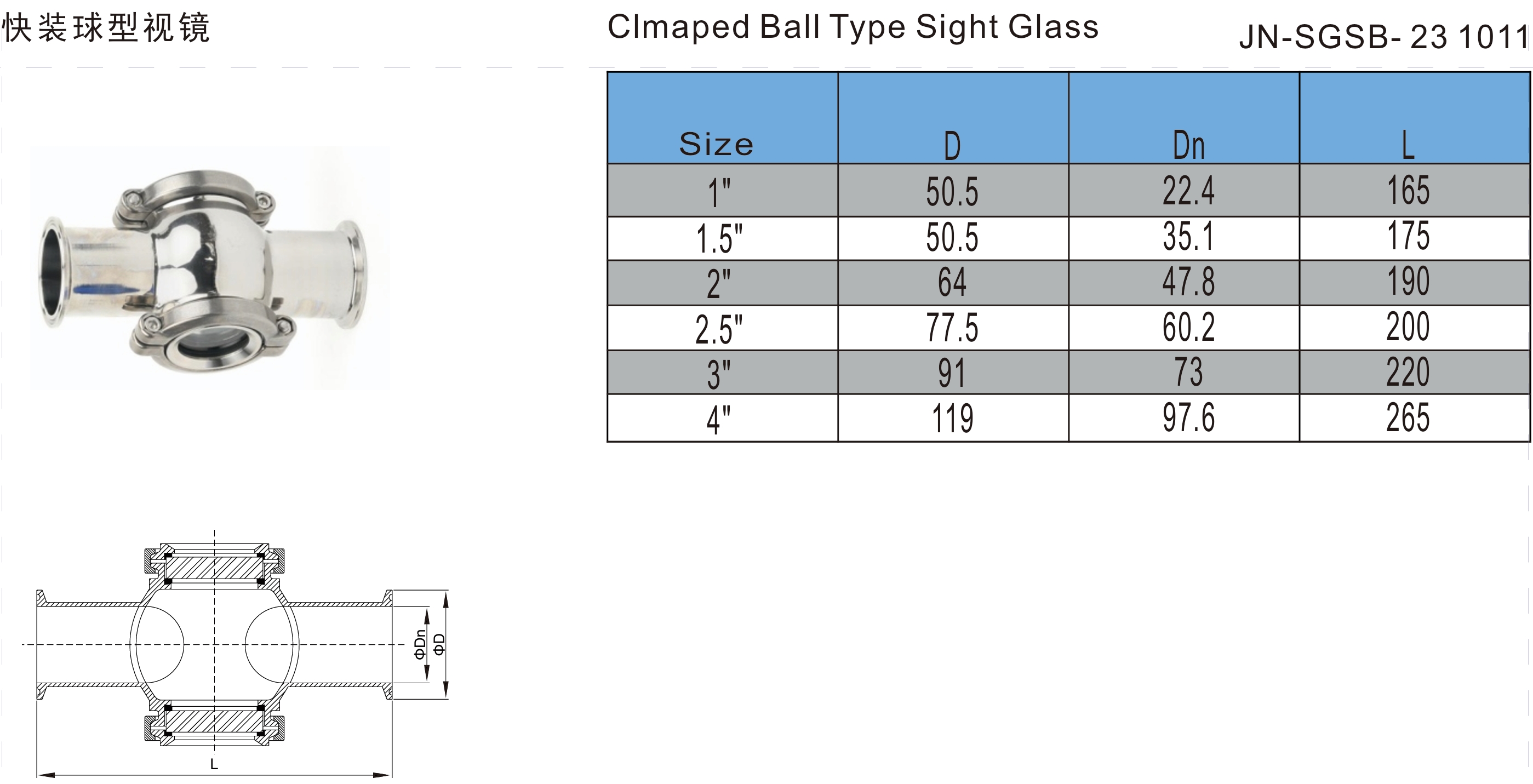

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● Spherical tempered glass window is used, with no blind spot, and fluid state can be observed in multiple directions, which is suitable for real-time monitoring of complex pipeline flow direction.

● Automatic welding and ≤0.4μm mirror polishing are used to eliminate dead corners of welds, reduce bacterial growth, and meet food and pharmaceutical grade hygiene requirements.

● The glass window is made of high temperature and high pressure resistant material, which can withstand high temperature above 150℃ and pressure above 10bar, and is suitable for steam sterilization and high pressure transportation environment.

● Reserve temperature, pressure, and flow sensor interfaces to support intelligent monitoring system integration, realize data acquisition and automatic control.

● Tempered glass with a thickness of more than 5mm is used, which can withstand fluid impact and physical collision, is not easy to break, and improves the service life of the mirror.

● Heating jacket, LED lighting or optical monitoring module can be added according to needs.

Application

Stainless steel sanitary four-way spherical sight glasses are widely used in the following industries: Food and beverage industry: monitor the flow status of liquids such as milk, juice, and beer. Dairy industry: observe liquid transportation in processes such as pasteurization and fermentation. Pharmaceutical industry: used for aseptic liquid transportation to ensure that production meets GMP standards. Biotechnology industry: monitor the flow of vaccines, fermentation tanks, and cell culture fluids. Fine chemical industry: used for high-purity chemical transportation to prevent impurity contamination. Cosmetics industry: observe the flow of production pipelines for creams, serums, perfumes, etc.

Working Principles

The working principle of the stainless steel sanitary four-way spherical sight glass is to provide 360°all-round visualization through a transparent spherical glass window, allowing operators to directly observe the flow state, color, bubbles or impurities of the fluid in the pipeline. The use of the stainless steel sanitary four-way spherical sight glass can monitor the flow and residue of the cleaning fluid in real time to ensure thorough cleaning and reduce the waste of water and chemical cleaning agents.

The options of the stainless steel sanitary four-way spherical sight glass include:

Material selection: 304, 316L stainless steel

Glass type: tempered glass, high temperature and high pressure resistant glass

Connection method: quick installation, welding, thread, flange

Sealing material: EPDM, PTFE, silicone, Viton

Surface treatment: mirror polishing, electrolytic polishing, sandblasting

Working pressure level: normal pressure, high pressure tolerance type

Additional functions: LED lighting, heating jacket, pressure/temperature sensor interface

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● Spherical tempered glass window is used, with no blind spot, and fluid state can be observed in multiple directions, which is suitable for real-time monitoring of complex pipeline flow direction.

● Automatic welding and ≤0.4μm mirror polishing are used to eliminate dead corners of welds, reduce bacterial growth, and meet food and pharmaceutical grade hygiene requirements.

● The glass window is made of high temperature and high pressure resistant material, which can withstand high temperature above 150℃ and pressure above 10bar, and is suitable for steam sterilization and high pressure transportation environment.

● Reserve temperature, pressure, and flow sensor interfaces to support intelligent monitoring system integration, realize data acquisition and automatic control.

● Tempered glass with a thickness of more than 5mm is used, which can withstand fluid impact and physical collision, is not easy to break, and improves the service life of the mirror.

● Heating jacket, LED lighting or optical monitoring module can be added according to needs.

Application

Stainless steel sanitary four-way spherical sight glasses are widely used in the following industries: Food and beverage industry: monitor the flow status of liquids such as milk, juice, and beer. Dairy industry: observe liquid transportation in processes such as pasteurization and fermentation. Pharmaceutical industry: used for aseptic liquid transportation to ensure that production meets GMP standards. Biotechnology industry: monitor the flow of vaccines, fermentation tanks, and cell culture fluids. Fine chemical industry: used for high-purity chemical transportation to prevent impurity contamination. Cosmetics industry: observe the flow of production pipelines for creams, serums, perfumes, etc.