Stainless Steel Hygienic Regulating Welded Mixproof Process Valve

These valves are versatile and designed in a way where there can be switch between different product or media without risking the contamination. These valves are composed of valve body, actuator. There are leakage detection holes which helps in inspecting visually with dissembling the valve. The operation of this valve is achieved through the combination of the valve seat arrangement. The design and the sealing mechanism provides a high level of reliability and product safety and ensuring there is no cross contamination.

Working Principles

The crucial principle of this valve is to control the flow to strop the cross contamination while enabling the separation of 2 media. This valve is controlled by means of compressed air through a remote location. This has 2 individual plugs and seals for separating the liquid. The space left between the seals forms a leakage chamber. This chamber remains closed when the valve is open. The valves are cleaned by clean in place connection.

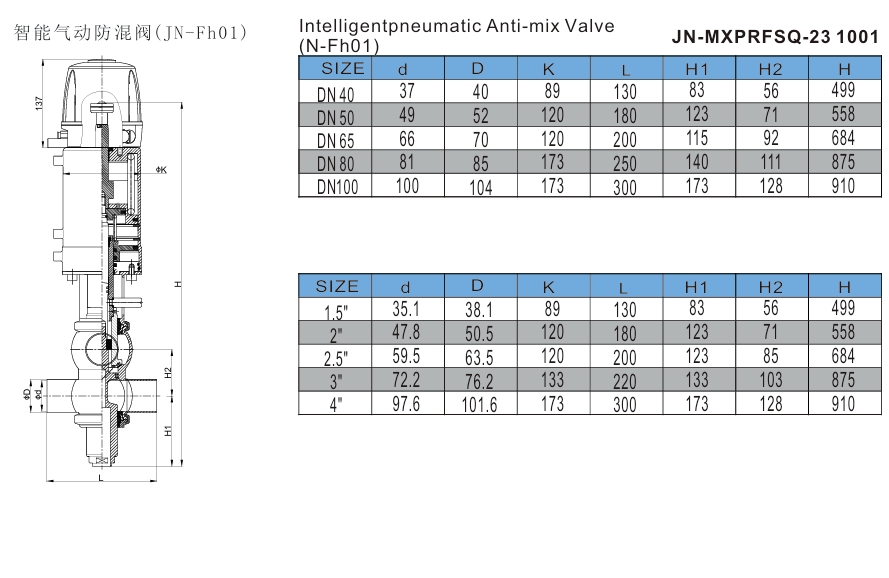

Stainless Steel Mixproof Valve Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 10 bar |

Max temperature | -5 °C to 125 °C |

Seals | EPDM, NBR, PTFE |

End connections | Tri clamp, DIN, SMS, flanged, welded |

Features

●Prevention of cross contamination

●Flexible and efficient

●Easy maintenance and cleaning

● Safe and reliable

●Product quality

●Leak protection

Application

This valves are applicable more in the areas where there are risk of cross contamination. It is used in industries like food and beverage industries, pharmaceutical, biotechnological, cosmetics, personal care and others.

Working Principles

The crucial principle of this valve is to control the flow to strop the cross contamination while enabling the separation of 2 media. This valve is controlled by means of compressed air through a remote location. This has 2 individual plugs and seals for separating the liquid. The space left between the seals forms a leakage chamber. This chamber remains closed when the valve is open. The valves are cleaned by clean in place connection.

Feature and Specification

Stainless Steel Mixproof Valve Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 10 bar |

Max temperature | -5 °C to 125 °C |

Seals | EPDM, NBR, PTFE |

End connections | Tri clamp, DIN, SMS, flanged, welded |

Features

●Prevention of cross contamination

●Flexible and efficient

●Easy maintenance and cleaning

● Safe and reliable

●Product quality

●Leak protection

Application

This valves are applicable more in the areas where there are risk of cross contamination. It is used in industries like food and beverage industries, pharmaceutical, biotechnological, cosmetics, personal care and others.