| Availability: | |

|---|---|

| Quantity: | |

JN-DPHV-23 1008-BJ

JONENG

8481804090

Stainless Steel Hygienic Thread Electric Actuator Straight Ball Valve

The stainless steel sanitary straight-through ball valve electric actuator is designed to achieve high automation and precise control to solve the shortcomings of manual operation. It realizes precise adjustment of the fluid through electric drive and is suitable for production environments with high hygiene requirements such as food and pharmaceuticals. The design takes into account the characteristics of corrosion resistance, high temperature resistance, and easy cleaning to ensure long-term stable operation under high cleanliness requirements, while reducing manual intervention and improving the safety, efficiency and flexibility of the system and production line. Through intelligent control, it can also seamlessly connect with modern industrial automation systems to further improve production efficiency.

Working Principles

The working principle of the stainless steel sanitary straight-through ball valve electric actuator is to control the rotation of the ball valve by driving the transmission device in the actuator through the motor. When receiving the control signal, the actuator rotates the ball valve to adjust the flow or switch state of the fluid. The electric actuator accurately adjusts the valve position according to the preset program or control signal to ensure the stability and accuracy of fluid control. The use of stainless steel sanitary straight-through ball valve electric actuator reduces the fluctuation and leakage of the fluid system through precise switching and adjustment functions, maintains the stability of the system, and ensures long-term and efficient operation.

The options of stainless steel sanitary straight-through ball valve electric actuator include:

Material: 304, 316L stainless steel.

Control mode: switch type, adjustment type, intelligent type.

Drive mode: AC electric, DC electric.

Protection level: IP65, IP67, etc.

Power supply mode: AC, DC.

Interface type: standard flange, threaded interface.

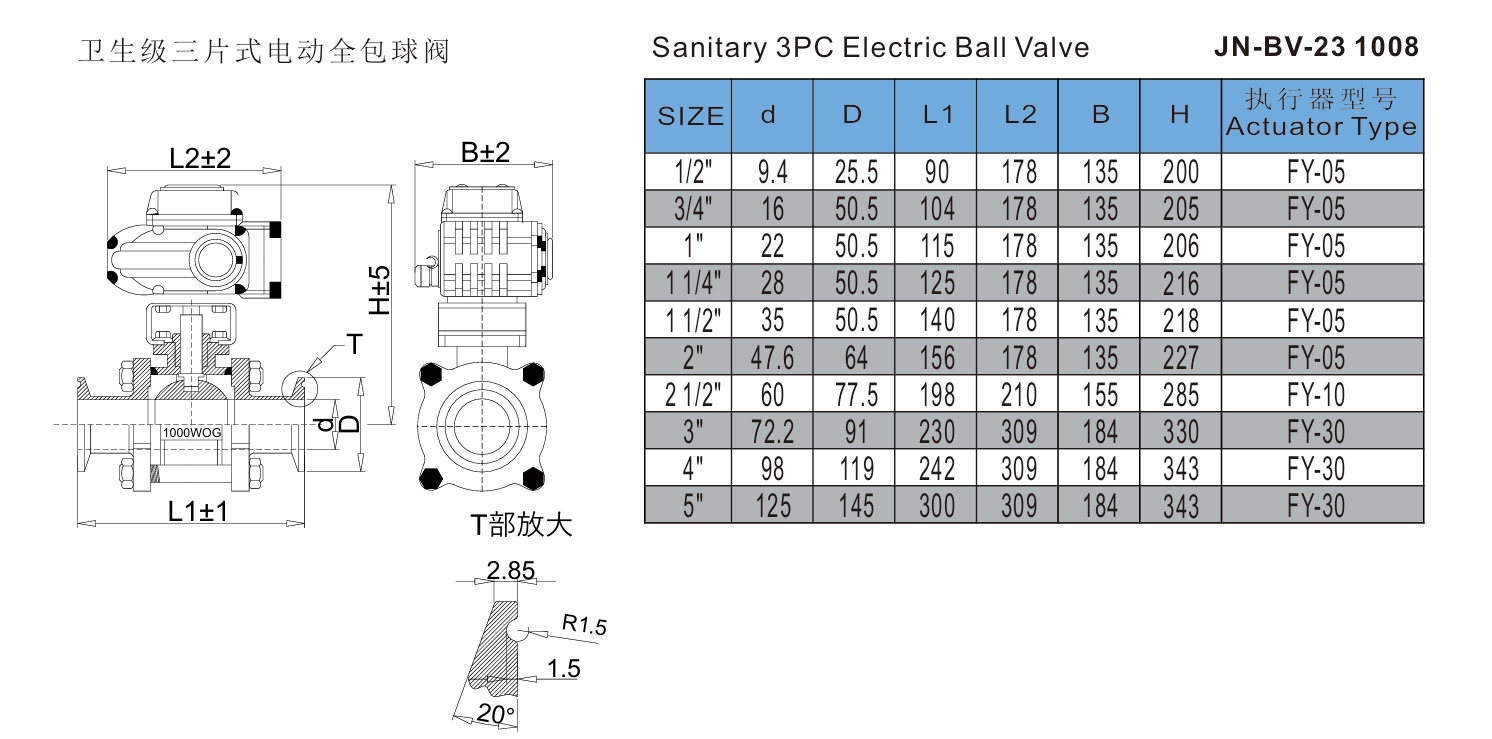

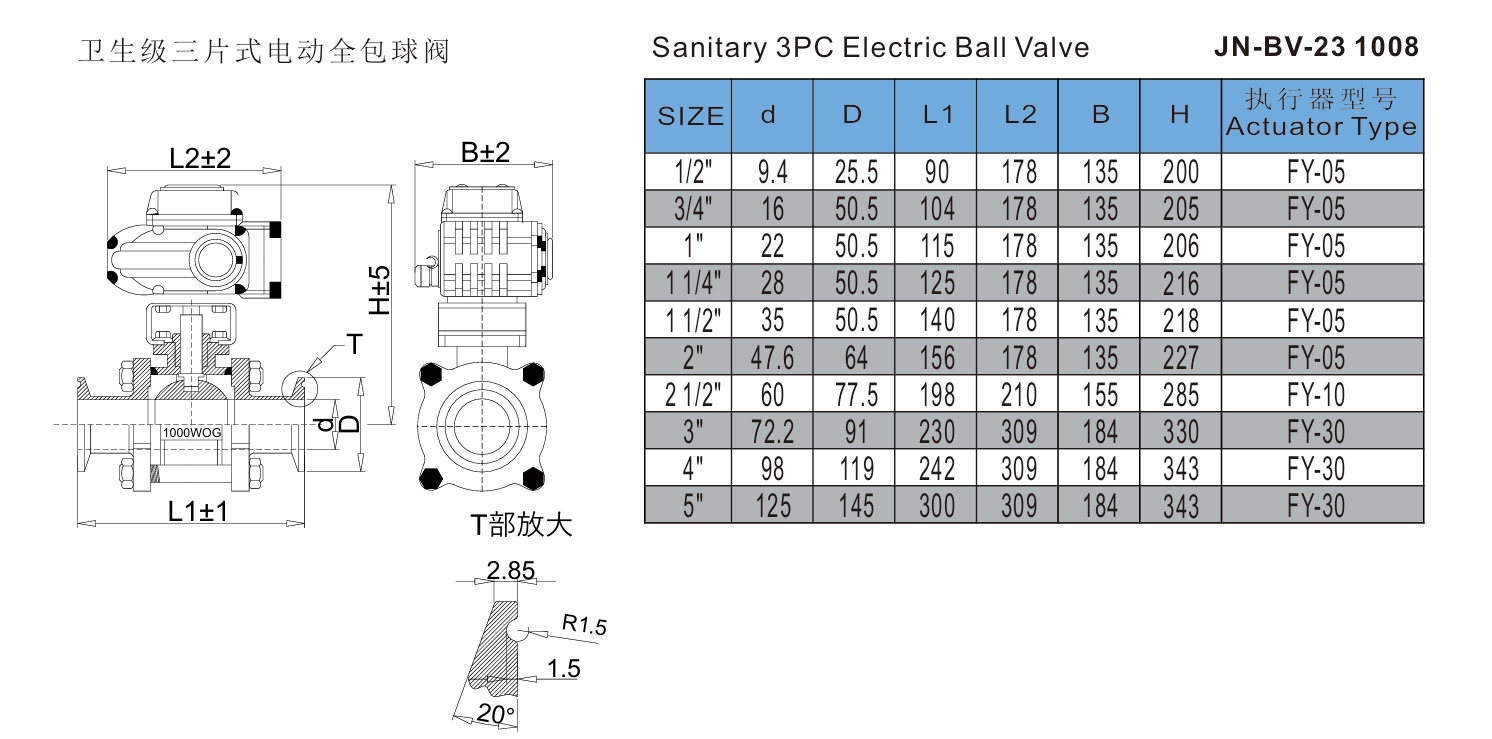

Specification Chart

Max. working pressure | 150 PSI |

Temperature range | -20° ~ +150°C or higher upon request |

Sizes available | 1/2" to 4" |

| End connection | Tri-Clamp, Butt-Weld, Flange, Threaded |

Body material | Stainless Steel 316L |

Ball material | Stainless Steel 316L |

Seal material | FDA Approved EPDM, Silicone, Viton |

Actuator Options | Manual, Pneumatic |

Surface Finish | Ra ≤ 0.8μm (Standard), Ra |

Flow Control | Linear |

Features

● The stainless steel sanitary straight-through ball valve electric actuator has a built-in adaptive control system, which can automatically adjust the valve opening according to the fluid pressure and temperature to optimize the fluid transmission process.

● The stainless steel sanitary straight-through ball valve electric actuator is equipped with a high-precision position sensor to ensure that the valve opening is accurate after each adjustment, and real-time feedback is given to the control system to achieve closed-loop control.

● The stainless steel sanitary straight-through ball valve electric actuator supports multiple communication protocols such as MODBUS and Profibus, and can be seamlessly integrated with modern automation control systems to meet different industrial control needs.

● The stainless steel sanitary straight-through ball valve electric actuator is equipped with a high-speed response motor to ensure that the valve can be opened or closed quickly, meet the needs of rapid adjustment, and avoid excessive reaction time.

● The stainless steel sanitary straight-through ball valve electric actuator is designed with an explosion-proof circuit and an explosion-proof shell certification to ensure safety when used in flammable and explosive environments.

● The stainless steel sanitary straight-through ball valve electric actuator integrates a fault prediction system, which can analyze the equipment status according to the operating data, alarm in advance and provide fault warning to avoid sudden shutdown.

Application

Stainless steel sanitary welded constant pressure valves are mainly used in the following industries: Food industry: ensure stable flow and hygiene requirements of fluids during the production process. Pharmaceutical industry: ensure constant pressure during the pharmaceutical process to avoid pollution and quality fluctuations. Beverage industry: accurately control fluid pressure to ensure stable quality and taste of beverages. Chemical industry: stabilize chemical reaction pressure to prevent pressure fluctuations from affecting production. Biopharmaceutical industry: prevent microbial contamination and ensure the cleanliness of the drug production process. Water treatment industry: adjust water flow pressure to ensure stability and efficiency of the water treatment process.

Working Principles

The working principle of the stainless steel sanitary straight-through ball valve electric actuator is to control the rotation of the ball valve by driving the transmission device in the actuator through the motor. When receiving the control signal, the actuator rotates the ball valve to adjust the flow or switch state of the fluid. The electric actuator accurately adjusts the valve position according to the preset program or control signal to ensure the stability and accuracy of fluid control. The use of stainless steel sanitary straight-through ball valve electric actuator reduces the fluctuation and leakage of the fluid system through precise switching and adjustment functions, maintains the stability of the system, and ensures long-term and efficient operation.

The options of stainless steel sanitary straight-through ball valve electric actuator include:

Material: 304, 316L stainless steel.

Control mode: switch type, adjustment type, intelligent type.

Drive mode: AC electric, DC electric.

Protection level: IP65, IP67, etc.

Power supply mode: AC, DC.

Interface type: standard flange, threaded interface.

Specification Chart

Max. working pressure | 150 PSI |

Temperature range | -20° ~ +150°C or higher upon request |

Sizes available | 1/2" to 4" |

End connection | Tri-Clamp, Butt-Weld, Flange, Threaded |

Body material | Stainless Steel 316L |

Ball material | Stainless Steel 316L |

Seal material | FDA Approved EPDM, Silicone, Viton |

Actuator Options | Manual, Pneumatic |

Surface Finish | Ra ≤ 0.8μm (Standard), Ra |

Flow Control | Linear |

Features

● The stainless steel sanitary straight-through ball valve electric actuator has a built-in adaptive control system, which can automatically adjust the valve opening according to the fluid pressure and temperature to optimize the fluid transmission process.

● The stainless steel sanitary straight-through ball valve electric actuator is equipped with a high-precision position sensor to ensure that the valve opening is accurate after each adjustment, and real-time feedback is given to the control system to achieve closed-loop control.

● The stainless steel sanitary straight-through ball valve electric actuator supports multiple communication protocols such as MODBUS and Profibus, and can be seamlessly integrated with modern automation control systems to meet different industrial control needs.

● The stainless steel sanitary straight-through ball valve electric actuator is equipped with a high-speed response motor to ensure that the valve can be opened or closed quickly, meet the needs of rapid adjustment, and avoid excessive reaction time.

● The stainless steel sanitary straight-through ball valve electric actuator is designed with an explosion-proof circuit and an explosion-proof shell certification to ensure safety when used in flammable and explosive environments.

● The stainless steel sanitary straight-through ball valve electric actuator integrates a fault prediction system, which can analyze the equipment status according to the operating data, alarm in advance and provide fault warning to avoid sudden shutdown.

Application

Stainless steel sanitary welded constant pressure valves are mainly used in the following industries: Food industry: ensure stable flow and hygiene requirements of fluids during the production process. Pharmaceutical industry: ensure constant pressure during the pharmaceutical process to avoid pollution and quality fluctuations. Beverage industry: accurately control fluid pressure to ensure stable quality and taste of beverages. Chemical industry: stabilize chemical reaction pressure to prevent pressure fluctuations from affecting production. Biopharmaceutical industry: prevent microbial contamination and ensure the cleanliness of the drug production process. Water treatment industry: adjust water flow pressure to ensure stability and efficiency of the water treatment process.