| Availability: | |

|---|---|

| Quantity: | |

JN-DPHV-23 1008-BJ

JONENG

8481804090

Stainless Steel Food Grade Weld 3 Way Ball Valve

The main purpose of the stainless steel sanitary three-way ball valve design is to provide efficient and safe fluid switching, diversion or mixing functions in pipeline systems with strict sanitary conditions. It uses innovative ball control technology to ensure that the sealing and system stability are maintained when the fluid flow direction changes. At the same time, its structure is simple and easy to clean, which can effectively reduce the accumulation of bacteria and impurities, adapt to high-pressure and high-temperature environments, and meet the special needs of food, pharmaceutical and other industries for sanitary, pure and efficient fluid control.

Working Principles

The working principle of the stainless steel sanitary three-way ball valve is to control the flow direction of the fluid by rotating the ball. There are three channels inside the ball. When the ball rotates, the fluid can be switched or diverted between the three ports. Through the knob or drive device on the valve body, the operator can adjust the rotation angle of the ball to achieve fluid distribution, switching or mixing functions in the pipeline system. The precise fit between the ball and the valve seat ensures the sealing performance and effectively prevents fluid leakage.

The options of the stainless steel sanitary three-way ball valve include:

Drive mode: manual, pneumatic, electric

Connection mode: clamp connection, threaded connection, welding

Ball material: stainless steel 304, 316L

Seal material: fluororubber, silicone, EPDM

Valve type: L-type, T-type, straight-through type

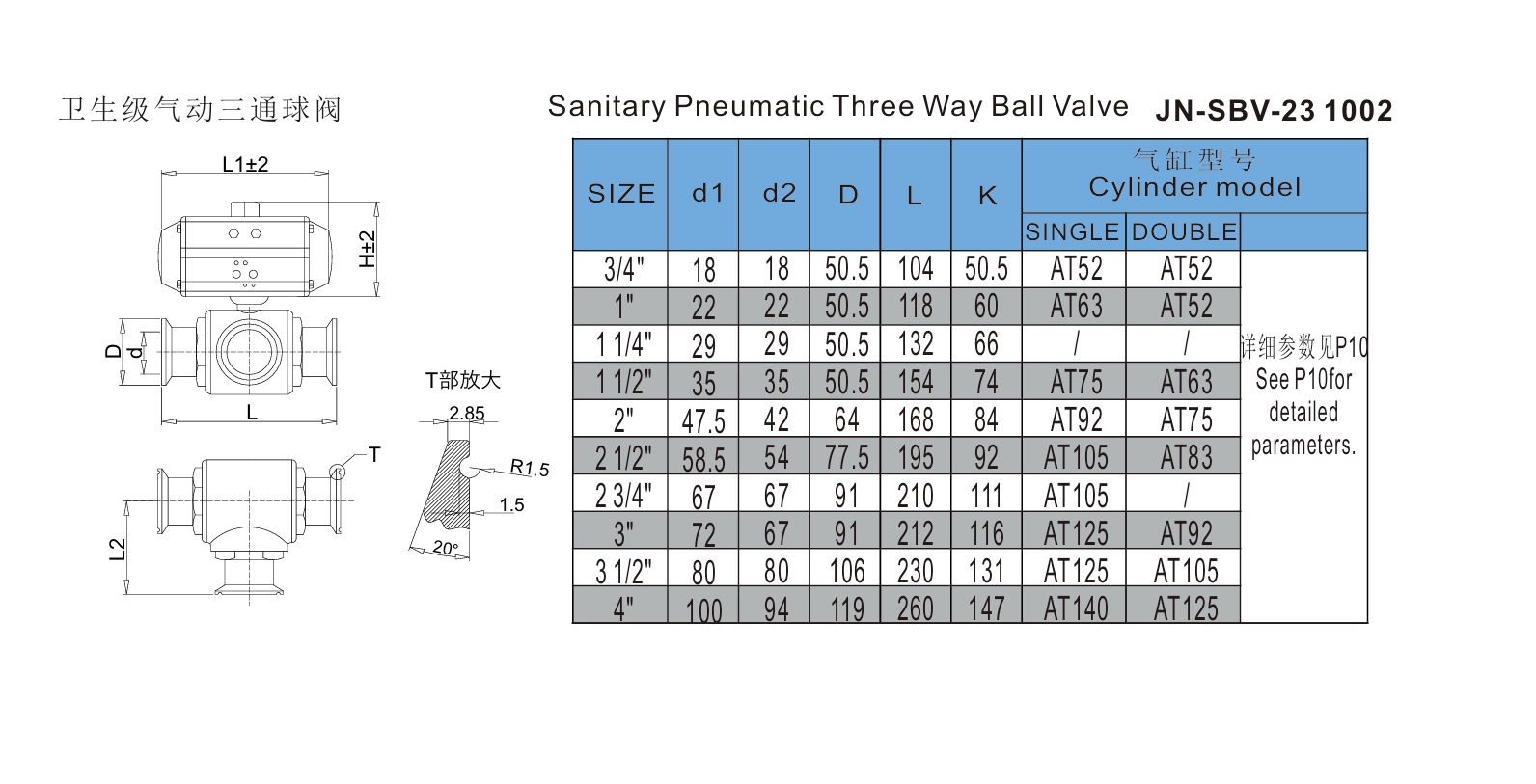

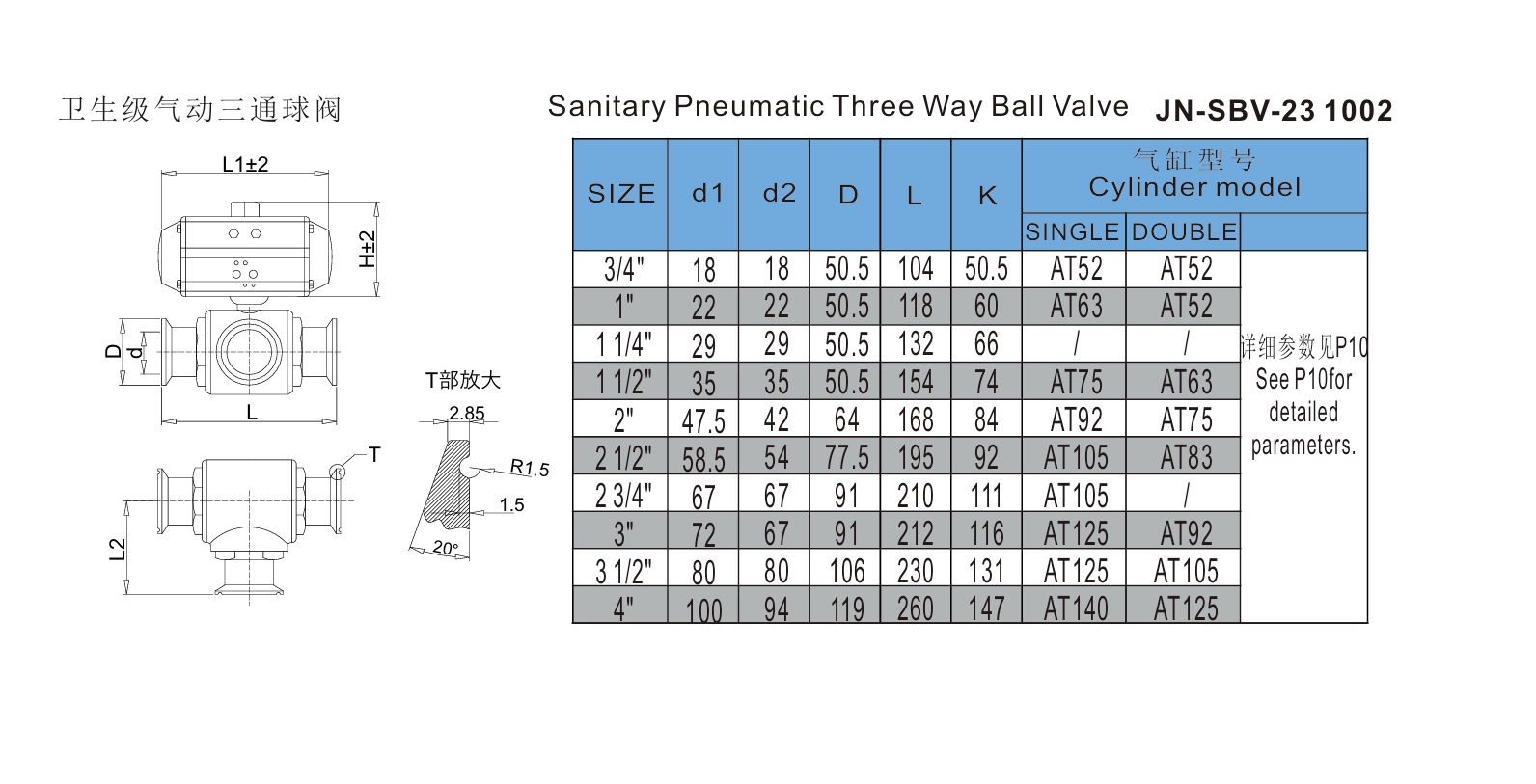

Specification Chart

Max. working pressure | 150 PSI |

Temperature range | -20° ~ +150°C or higher upon request |

Sizes available | 1/2" to 4" |

| End connection | Tri-Clamp, Butt-Weld, Flange, Threaded |

Body material | Stainless Steel 316L |

Ball material | Stainless Steel 316L |

Seal material | FDA Approved EPDM, Silicone, Viton |

Actuator Options | Manual, Pneumatic |

Surface Finish | Ra ≤ 0.8μm (Standard), Ra |

Flow Control | Linear |

Features

● The stainless steel sanitary three-way ball valve ball adopts advanced processing technology to ensure smooth surface and high precision, and improve the accuracy and stability of flow control.

● The stainless steel sanitary three-way ball valve optimizes the design of the internal flow channel of the ball valve to make the fluid flow more smoothly in the valve and improve the system efficiency.

● The special ball structure design of the stainless steel sanitary three-way ball valve can achieve self-cleaning effect during the fluid flow process and improve the hygiene standard.

● The internal design of the stainless steel sanitary three-way ball valve adopts a dead zone-free structure to avoid fluid retention inside the valve and effectively reduce cross contamination.

● The stainless steel sanitary three-way ball valve adopts a clamp connection and a simple disassembly and assembly structure, which makes installation and maintenance more convenient and improves work efficiency.

● The stainless steel sanitary three-way ball valve ball valve design adopts a low-torque operating system, and the switch operation is also more labor-saving, which improves the convenience of operation.

Application

Stainless steel sanitary three-way ball valves are widely used in the following industries: Food industry: used for liquid diversion and confluence to ensure hygiene requirements during food processing. Beverage industry: used for precise distribution of fluids in beverage production lines to ensure that the fluid is contaminated. Pharmaceutical industry: ensure high hygiene requirements for fluids in the production of pharmaceuticals to prevent cross contamination. Cosmetics industry: control the precise flow of fluids in the production of cosmetics to meet high hygiene standards. Biopharmaceutical industry: used in the production of biological products to ensure that the fluid system meets the requirements of a sterile environment.

Working Principles

The working principle of the stainless steel sanitary three-way ball valve is to control the flow direction of the fluid by rotating the ball. There are three channels inside the ball. When the ball rotates, the fluid can be switched or diverted between the three ports. Through the knob or drive device on the valve body, the operator can adjust the rotation angle of the ball to achieve fluid distribution, switching or mixing functions in the pipeline system. The precise fit between the ball and the valve seat ensures the sealing performance and effectively prevents fluid leakage.

The options of the stainless steel sanitary three-way ball valve include:

Drive mode: manual, pneumatic, electric

Connection mode: clamp connection, threaded connection, welding

Ball material: stainless steel 304, 316L

Seal material: fluororubber, silicone, EPDM

Valve type: L-type, T-type, straight-through type

Specification Chart

Max. working pressure | 150 PSI |

Temperature range | -20° ~ +150°C or higher upon request |

Sizes available | 1/2" to 4" |

End connection | Tri-Clamp, Butt-Weld, Flange, Threaded |

Body material | Stainless Steel 316L |

Ball material | Stainless Steel 316L |

Seal material | FDA Approved EPDM, Silicone, Viton |

Actuator Options | Manual, Pneumatic |

Surface Finish | Ra ≤ 0.8μm (Standard), Ra |

Flow Control | Linear |

Features

● The stainless steel sanitary three-way ball valve ball adopts advanced processing technology to ensure smooth surface and high precision, and improve the accuracy and stability of flow control.

● The stainless steel sanitary three-way ball valve optimizes the design of the internal flow channel of the ball valve to make the fluid flow more smoothly in the valve and improve the system efficiency.

● The special ball structure design of the stainless steel sanitary three-way ball valve can achieve self-cleaning effect during the fluid flow process and improve the hygiene standard.

● The internal design of the stainless steel sanitary three-way ball valve adopts a dead zone-free structure to avoid fluid retention inside the valve and effectively reduce cross contamination.

● The stainless steel sanitary three-way ball valve adopts a clamp connection and a simple disassembly and assembly structure, which makes installation and maintenance more convenient and improves work efficiency.

● The stainless steel sanitary three-way ball valve ball valve design adopts a low-torque operating system, and the switch operation is also more labor-saving, which improves the convenience of operation.

Application

Stainless steel sanitary three-way ball valves are widely used in the following industries: Food industry: used for liquid diversion and confluence to ensure hygiene requirements during food processing. Beverage industry: used for precise distribution of fluids in beverage production lines to ensure that the fluid is contaminated. Pharmaceutical industry: ensure high hygiene requirements for fluids in the production of pharmaceuticals to prevent cross contamination. Cosmetics industry: control the precise flow of fluids in the production of cosmetics to meet high hygiene standards. Biopharmaceutical industry: used in the production of biological products to ensure that the fluid system meets the requirements of a sterile environment.