| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary Y-thread filter is a pipeline filtration device with a Y-shaped structure. It filters impurities in the fluid through an internal precision filter. Its main purpose is to protect the equipment from damage by solid particles and impurities. The stainless steel sanitary Y-thread filter is usually used in pipeline systems that require precision filtration and is generally installed at the entrance or water inlet of the pipeline. The common types of stainless steel sanitary Y-thread filters are mainly the following: mesh filter, orifice filter, screen filter, multi-layer filter element filter, single-layer filter element filter.

JN-STZT-23 1005

JONENG

8421219990

Stainless Steel Hygienic Water Filter Cartridge Y-Type Threaded Filter

The stainless steel sanitary Y-thread filter is designed to improve the safety and efficiency of the pipeline system. Through its unique Y-shaped structure, it can accurately filter solid impurities in liquids or gases, effectively preventing these impurities from entering downstream equipment or pipelines, causing blockage, wear or corrosion. This design enables the filter to not only have efficient impurity retention capabilities, but also be quickly installed and maintained in space-constrained environments, reducing downtime. In industries such as food processing, chemical production, and pharmaceuticals that require high equipment precision, the Y-thread filter can ensure process stability and product quality.

Working Principles

The working principle of the stainless steel sanitary Y-type threaded filter is to remove solid impurities in the pipeline through its Y-shaped structure and built-in filter, using the pressure difference when the liquid or gas flows and the filtering effect of the screen. When the liquid or gas flows into the filter, the fluid first enters the inlet of the filter, passes through the filter or filter element, and the impurities are trapped on the surface of the filter, while the clean fluid flows out through the filter and enters the downstream of the pipeline. As the fluid flows, the impurities in the filter gradually accumulate, forming a pressure difference, which prompts the fluid to continue to flow through the gaps in the filter. When cleaning is required, the accumulated impurities are removed through the drain port to restore its filtration efficiency.

The options of the stainless steel sanitary Y-type threaded filter include:

Filter material: stainless steel 304, 316, 316L, etc., adapted to different corrosive environments.

Mesh size: Filters of different apertures can be selected to meet different precision requirements.

Connection method: Threaded connection can choose imperial or metric threads.

Drainage method: manual drainage, automatic drainage.

Filter element type: mesh filter element, screen filter element, orifice filter element, etc.

Pressure level: Select the appropriate level according to the working pressure of the pipeline system.

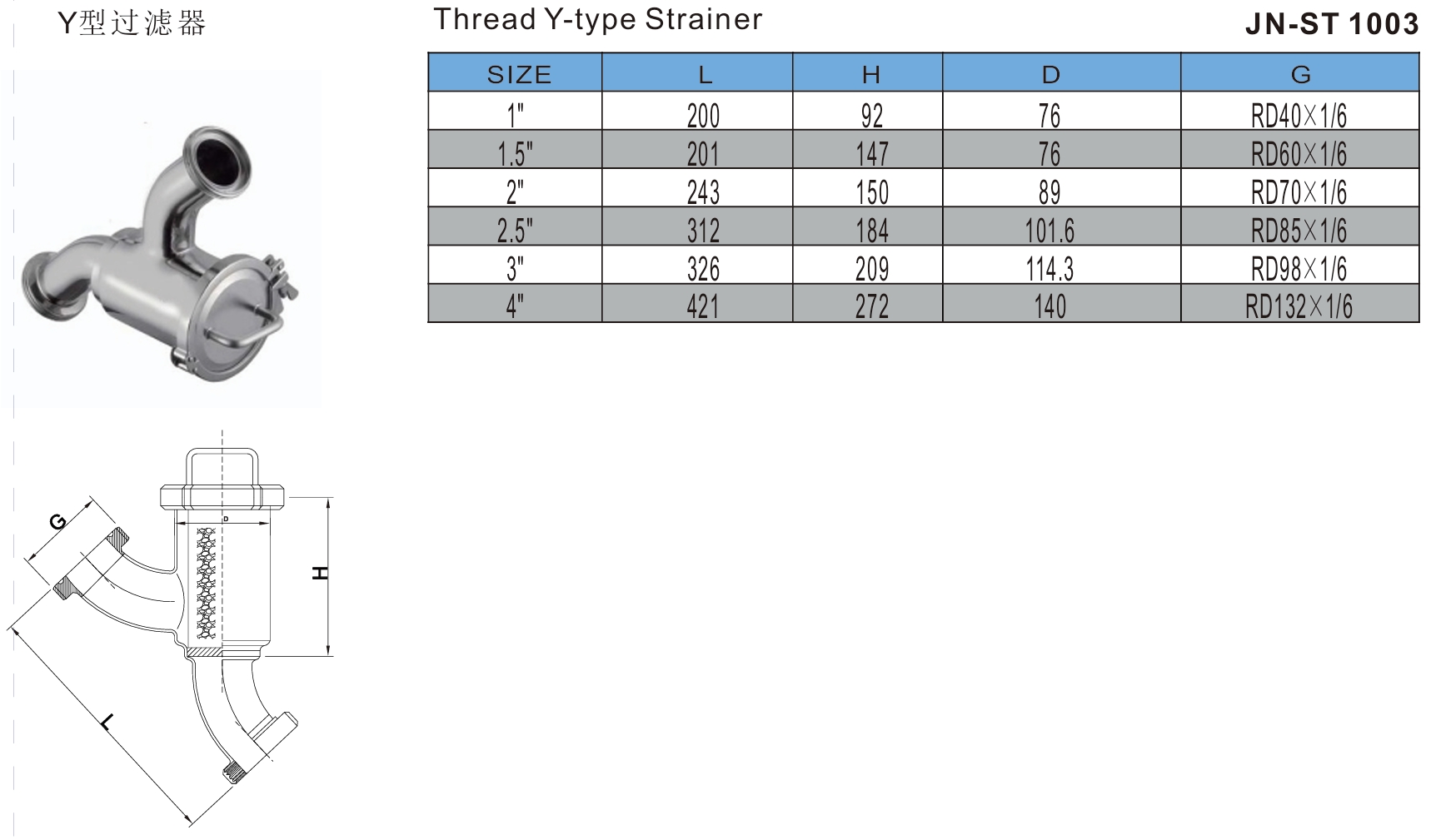

Specification Chart

Size | 1”-4” |

Material | AISI 316, AISI 304 |

Connection | Clamped, Welded, Threaded |

Gasket | Silicone, EPDM, Viton, PTFE |

Standard | 3A, DIN, SMS, ISO |

Mesh size | From 0.5mm to 2.0mm |

Screen | From 30 mesh to 300 mesh |

Internal Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

| External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The stainless steel sanitary Y-type threaded filter can realize the bidirectional flow function, ensuring efficient filtration under different flow directions.

● The stainless steel sanitary Y-type threaded filter is equipped with an intelligent dynamic cleaning function. When the fluid pressure reaches a certain threshold, the built-in automatic cleaning device will start to remove the impurities accumulated in the filter.

● The stainless steel sanitary Y-type threaded filter adopts a multi-layer filter design. The first layer filters larger particles, and the precision is gradually improved layer by layer.

● The stainless steel sanitary Y-type threaded filter allows reverse flow cleaning. The accumulated impurities are strongly flushed out by reverse water flow, ensuring the continuous high efficiency of the filter.

● The stainless steel sanitary Y-type threaded filter uses advanced fine control technology to ensure the consistency and accuracy of the pore size, avoiding the disadvantages of uneven pore size of traditional filter screens.

● The stainless steel sanitary Y-type threaded filter has been specially heat-treated and can withstand the flow of high-temperature fluids without deformation or material degradation.

Application

Stainless steel sanitary Y-type threaded filters are widely used in the following industries: Food processing: used to filter impurities in liquids to ensure food hygiene and safety. Pharmaceutical industry: filter liquids or gases to maintain a sterile environment in the production process. Chemical industry: remove solid impurities from chemical liquids to prevent equipment clogging. Drinking water treatment: effectively remove particles from water to ensure clean water quality. Biomedicine: filter culture fluids, etc. to prevent particulate contamination. Petroleum industry: filter solid matter from crude oil and its by-products. Refrigeration and air conditioning system: filter impurities in cooling water to extend equipment life.

Working Principles

The working principle of the stainless steel sanitary Y-type threaded filter is to remove solid impurities in the pipeline through its Y-shaped structure and built-in filter, using the pressure difference when the liquid or gas flows and the filtering effect of the screen. When the liquid or gas flows into the filter, the fluid first enters the inlet of the filter, passes through the filter or filter element, and the impurities are trapped on the surface of the filter, while the clean fluid flows out through the filter and enters the downstream of the pipeline. As the fluid flows, the impurities in the filter gradually accumulate, forming a pressure difference, which prompts the fluid to continue to flow through the gaps in the filter. When cleaning is required, the accumulated impurities are removed through the drain port to restore its filtration efficiency.

The options of the stainless steel sanitary Y-type threaded filter include:

Filter material: stainless steel 304, 316, 316L, etc., adapted to different corrosive environments.

Mesh size: Filters of different apertures can be selected to meet different precision requirements.

Connection method: Threaded connection can choose imperial or metric threads.

Drainage method: manual drainage, automatic drainage.

Filter element type: mesh filter element, screen filter element, orifice filter element, etc.

Pressure level: Select the appropriate level according to the working pressure of the pipeline system.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary Y-type threaded filter can realize the bidirectional flow function, ensuring efficient filtration under different flow directions.

● The stainless steel sanitary Y-type threaded filter is equipped with an intelligent dynamic cleaning function. When the fluid pressure reaches a certain threshold, the built-in automatic cleaning device will start to remove the impurities accumulated in the filter.

● The stainless steel sanitary Y-type threaded filter adopts a multi-layer filter design. The first layer filters larger particles, and the precision is gradually improved layer by layer.

● The stainless steel sanitary Y-type threaded filter allows reverse flow cleaning. The accumulated impurities are strongly flushed out by reverse water flow, ensuring the continuous high efficiency of the filter.

● The stainless steel sanitary Y-type threaded filter uses advanced fine control technology to ensure the consistency and accuracy of the pore size, avoiding the disadvantages of uneven pore size of traditional filter screens.

● The stainless steel sanitary Y-type threaded filter has been specially heat-treated and can withstand the flow of high-temperature fluids without deformation or material degradation.

Application

Stainless steel sanitary Y-type threaded filters are widely used in the following industries: Food processing: used to filter impurities in liquids to ensure food hygiene and safety. Pharmaceutical industry: filter liquids or gases to maintain a sterile environment in the production process. Chemical industry: remove solid impurities from chemical liquids to prevent equipment clogging. Drinking water treatment: effectively remove particles from water to ensure clean water quality. Biomedicine: filter culture fluids, etc. to prevent particulate contamination. Petroleum industry: filter solid matter from crude oil and its by-products. Refrigeration and air conditioning system: filter impurities in cooling water to extend equipment life.