| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless Steel Pneumatic DN80 ISO Piston Type Tank Bottom Valve

Stainless Steel Pneumatic DN80 ISO Piston Type Tank Bottom Valve is an automated discharge valve mounted at the bottom of process tanks. It uses a pneumatic piston actuator to provide fast, stable opening and closing, ensuring efficient material release, high sealing reliability, and hygienic performance for industrial applications

Working Principles

The working principle of a Stainless Steel Pneumatic DN80 ISO Piston Type Tank Bottom Valve relies on compressed air to drive a piston mechanism that controls the opening and closing of the valve. When air pressure is applied to the actuator, the piston moves linearly, pushing the valve stem to lift the sealing plug away from the seat and allowing media to discharge from the tank bottom through the DN80 outlet. Reversing or releasing the air pressure causes the piston to return to its original position, pressing the plug firmly against the seat to achieve tight shut-off. This pneumatic operation enables quick response, consistent actuation force, and reliable performance under frequent cycling. The valve design supports hygienic processing, withstands cleaning procedures, and ensures stable flow control in automated systems

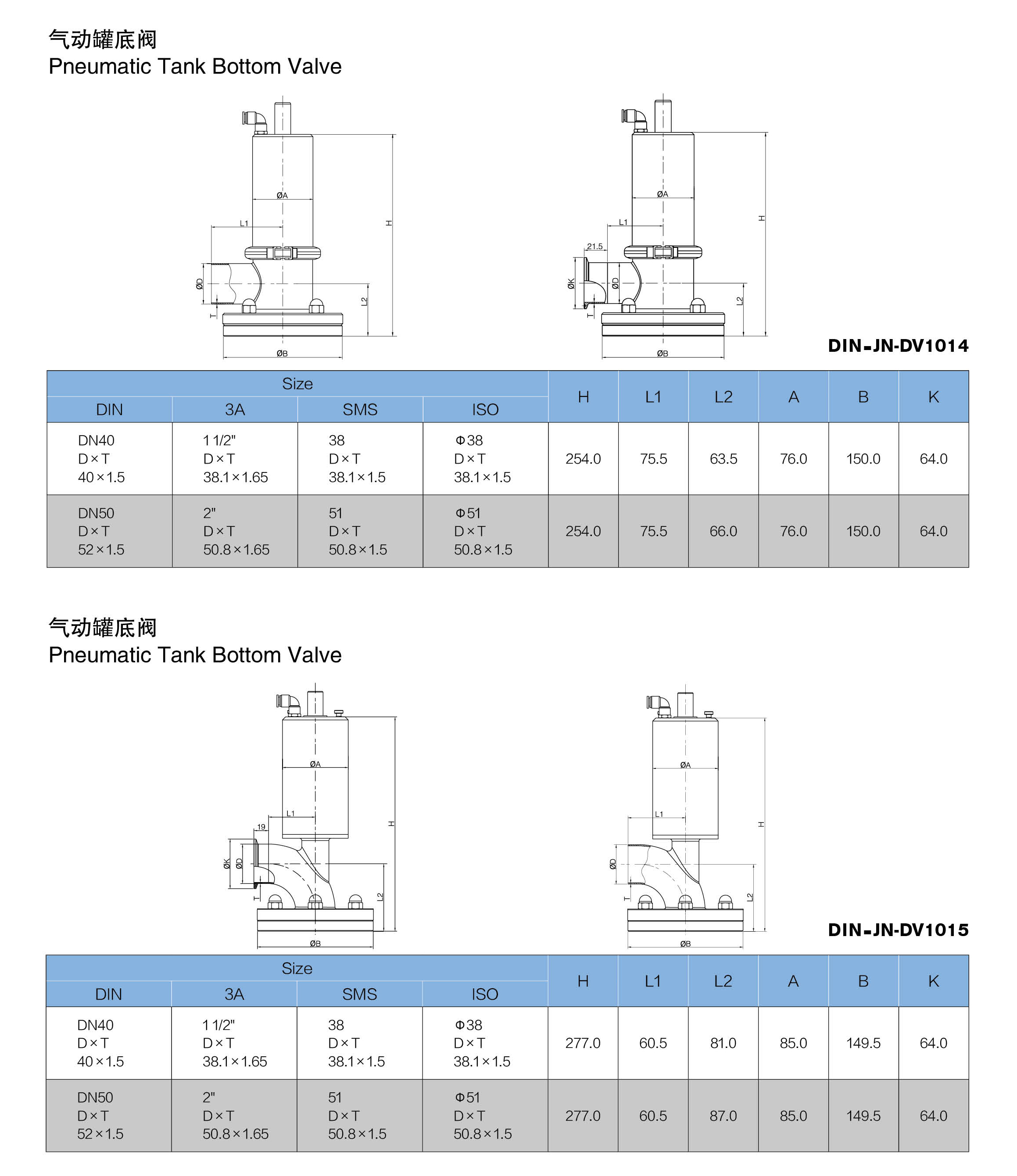

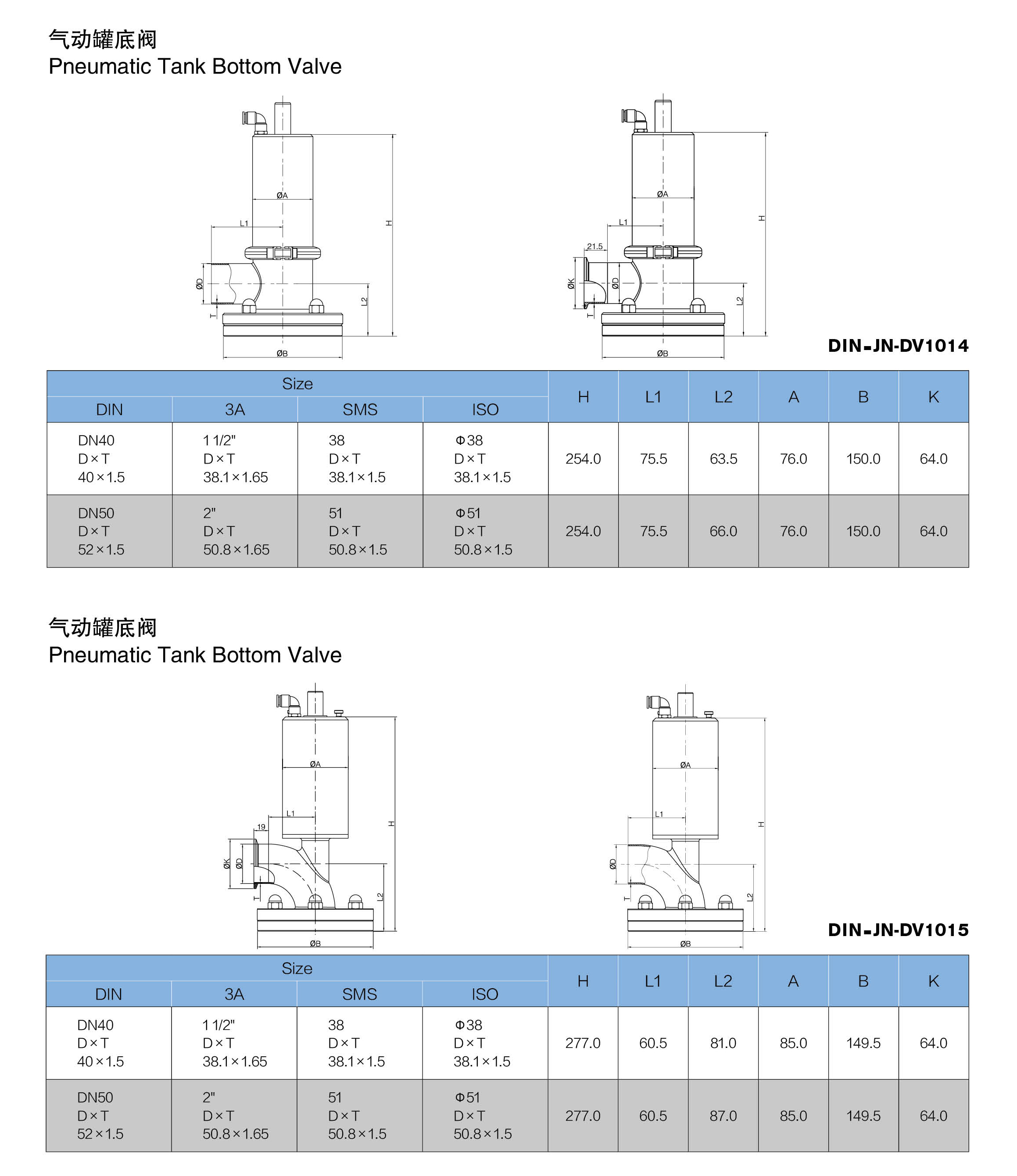

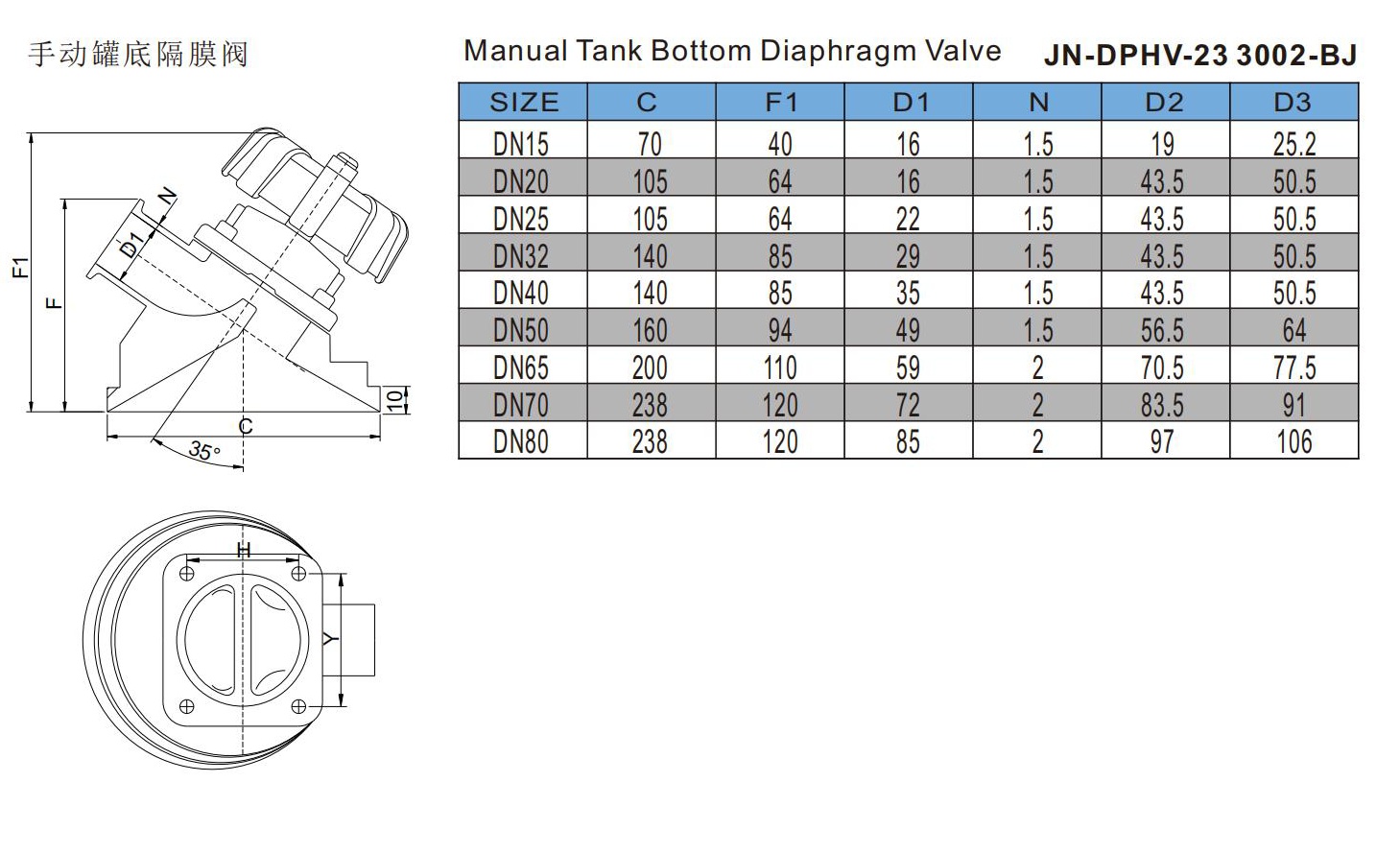

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

Equipped with a pneumatic piston actuator that delivers strong, stable linear force, ensuring fast response, consistent operation, and reliable opening and closing under frequent working cycles.

DN80 ISO standard connection allows easy integration with tank outlets and piping systems, providing secure installation and broad compatibility in industrial process equipment.

Constructed from high-quality stainless steel with smooth internal surfaces, offering excellent corrosion resistance and meeting hygienic requirements for clean process applications.

Tank bottom mounting design enables efficient material discharge by gravity, reducing residual buildup and improving overall process efficiency and product recovery.

Reliable sealing structure maintains tight shut-off performance, minimizing leakage risks while remaining suitable for automated systems and routine cleaning operations

Application

Stainless Steel Pneumatic DN80 ISO Piston Type Tank Bottom Valves are commonly used in chemical processing plants to discharge corrosive liquids or slurries from reaction vessels. They are also applied in food and beverage production for emptying mixing or storage tanks in automated lines. In addition, these valves are suitable for pharmaceutical and cosmetic manufacturing, where pneumatic control, reliable sealing, and efficient tank drainage are essential for maintaining stable production and consistent product quality

Working Principles

The working principle of a Stainless Steel Pneumatic DN80 ISO Piston Type Tank Bottom Valve relies on compressed air to drive a piston mechanism that controls the opening and closing of the valve. When air pressure is applied to the actuator, the piston moves linearly, pushing the valve stem to lift the sealing plug away from the seat and allowing media to discharge from the tank bottom through the DN80 outlet. Reversing or releasing the air pressure causes the piston to return to its original position, pressing the plug firmly against the seat to achieve tight shut-off. This pneumatic operation enables quick response, consistent actuation force, and reliable performance under frequent cycling. The valve design supports hygienic processing, withstands cleaning procedures, and ensures stable flow control in automated systems

Feature and Specification

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

Equipped with a pneumatic piston actuator that delivers strong, stable linear force, ensuring fast response, consistent operation, and reliable opening and closing under frequent working cycles.

DN80 ISO standard connection allows easy integration with tank outlets and piping systems, providing secure installation and broad compatibility in industrial process equipment.

Constructed from high-quality stainless steel with smooth internal surfaces, offering excellent corrosion resistance and meeting hygienic requirements for clean process applications.

Tank bottom mounting design enables efficient material discharge by gravity, reducing residual buildup and improving overall process efficiency and product recovery.

Reliable sealing structure maintains tight shut-off performance, minimizing leakage risks while remaining suitable for automated systems and routine cleaning operations

Application

Stainless Steel Pneumatic DN80 ISO Piston Type Tank Bottom Valves are commonly used in chemical processing plants to discharge corrosive liquids or slurries from reaction vessels. They are also applied in food and beverage production for emptying mixing or storage tanks in automated lines. In addition, these valves are suitable for pharmaceutical and cosmetic manufacturing, where pneumatic control, reliable sealing, and efficient tank drainage are essential for maintaining stable production and consistent product quality