| Availability: | |

|---|---|

| Quantity: | |

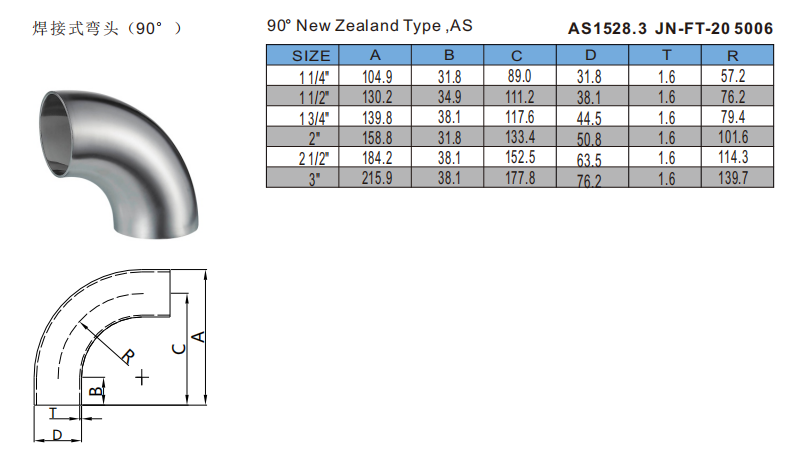

AS1528.3 JN-FT-20 5006

JONENG

7307290000

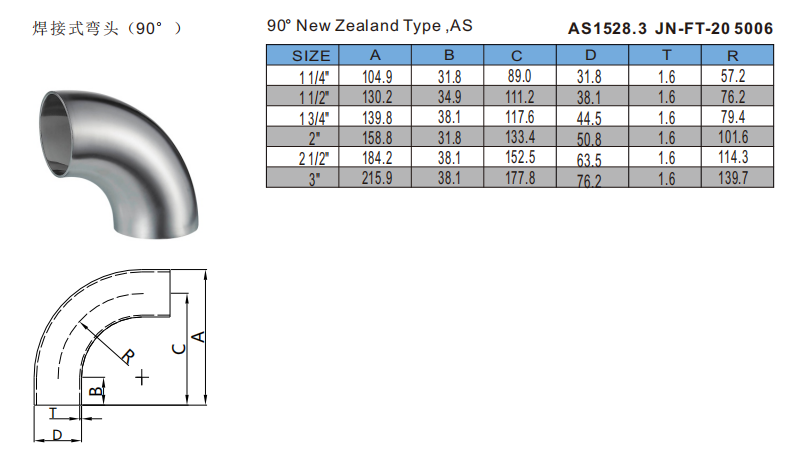

Stainless Steel Polished Weld 90 Degree Bend Pipe Elbow

The purpose of the design of stainless steel sanitary elbows is to achieve the change of fluid flow direction in the pipeline system while maintaining the high hygiene standards of the system. By changing the direction of the pipeline, the sanitary elbow can effectively connect the pipeline, save space and optimize the layout, ensure smooth fluid flow, and reduce resistance and fouling.

Working Principles

The working principle of stainless steel sanitary elbow is to make the fluid flow smoothly and maintain sanitation requirements when turning through smooth, precise design and high-quality materials. It is widely used in industries with high requirements for fluid quality. The use of stainless steel sanitary elbows can achieve a smooth change in the flow direction of the fluid in the pipeline system, reduce flow resistance, and ensure that the fluid is unobstructed. Its smooth inner surface effectively prevents dirt accumulation and bacterial growth, meets high hygiene standards, and ensures that the fluid quality is not contaminated. At the same time, the corrosion resistance and high temperature resistance of stainless steel materials enable the elbow to work stably for a long time in harsh environments. It is widely used in food, beverage, pharmaceutical and other industries to ensure the sanitation, safety and efficient operation of the system.

The options of stainless steel sanitary elbows include:

Elbow angle: 90 degrees, 45 degrees, 60 degrees, etc.

Radius type: short radius, long radius.

Connection method: welding, threaded connection, quick connection, etc.

Material selection: 304, 316L and other stainless steel materials.

Size specification: select according to the pipe size.

Surface treatment: mirror polishing, matte treatment, etc.

Customized design: customized angles, sizes, etc. according to special needs.

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The inner and outer surfaces of stainless steel sanitary elbows are usually finely processed to reduce bacterial growth and dirt accumulation.

● The inner surface of the stainless steel sanitary elbow is smooth, and the design avoids complex turning angles, with low fluid resistance and reduced energy loss during the flow process.

● The no-dead-angle design of the stainless steel sanitary elbow makes cleaning easier and can effectively remove sediments and microorganisms.

● The stainless steel sanitary elbow material provides high strength and excellent pressure resistance.

● The design of the stainless steel sanitary elbow avoids dead corners and water accumulation areas inside the pipeline to ensure smooth fluid flow.

● The stainless steel sanitary elbow provides a variety of connection methods (such as welding, quick installation, and threaded connection) to make installation and disassembly easier.

Application

Stainless steel sanitary elbows are widely used in the following industry fields: Food industry: used for liquid transportation, processing and packaging equipment. Pharmaceutical industry: ensure the hygiene and safety of fluids in the production process of drugs. Beverage industry: used for beverage production and packaging pipeline systems. Cosmetic industry: delivery system for liquid and cream products. Chemical industry: pipeline transportation of chemical substances, requiring high hygiene standards. Biopharmaceuticals: sterile fluid pipelines for the production of biological products and drugs. Dairy industry: pipeline transportation during the production of dairy products. Medical industry: fluid systems for the production of medical equipment and drugs.

Working Principles

The working principle of stainless steel sanitary elbow is to make the fluid flow smoothly and maintain sanitation requirements when turning through smooth, precise design and high-quality materials. It is widely used in industries with high requirements for fluid quality. The use of stainless steel sanitary elbows can achieve a smooth change in the flow direction of the fluid in the pipeline system, reduce flow resistance, and ensure that the fluid is unobstructed. Its smooth inner surface effectively prevents dirt accumulation and bacterial growth, meets high hygiene standards, and ensures that the fluid quality is not contaminated. At the same time, the corrosion resistance and high temperature resistance of stainless steel materials enable the elbow to work stably for a long time in harsh environments. It is widely used in food, beverage, pharmaceutical and other industries to ensure the sanitation, safety and efficient operation of the system.

The options of stainless steel sanitary elbows include:

Elbow angle: 90 degrees, 45 degrees, 60 degrees, etc.

Radius type: short radius, long radius.

Connection method: welding, threaded connection, quick connection, etc.

Material selection: 304, 316L and other stainless steel materials.

Size specification: select according to the pipe size.

Surface treatment: mirror polishing, matte treatment, etc.

Customized design: customized angles, sizes, etc. according to special needs.

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The inner and outer surfaces of stainless steel sanitary elbows are usually finely processed to reduce bacterial growth and dirt accumulation.

● The inner surface of the stainless steel sanitary elbow is smooth, and the design avoids complex turning angles, with low fluid resistance and reduced energy loss during the flow process.

● The no-dead-angle design of the stainless steel sanitary elbow makes cleaning easier and can effectively remove sediments and microorganisms.

● The stainless steel sanitary elbow material provides high strength and excellent pressure resistance.

● The design of the stainless steel sanitary elbow avoids dead corners and water accumulation areas inside the pipeline to ensure smooth fluid flow.

● The stainless steel sanitary elbow provides a variety of connection methods (such as welding, quick installation, and threaded connection) to make installation and disassembly easier.

Application

Stainless steel sanitary elbows are widely used in the following industry fields: Food industry: used for liquid transportation, processing and packaging equipment. Pharmaceutical industry: ensure the hygiene and safety of fluids in the production process of drugs. Beverage industry: used for beverage production and packaging pipeline systems. Cosmetic industry: delivery system for liquid and cream products. Chemical industry: pipeline transportation of chemical substances, requiring high hygiene standards. Biopharmaceuticals: sterile fluid pipelines for the production of biological products and drugs. Dairy industry: pipeline transportation during the production of dairy products. Medical industry: fluid systems for the production of medical equipment and drugs.