| Availability: | |

|---|---|

| Quantity: | |

This type of joint not only has the corrosion resistance and high strength of stainless steel, but also improves the appearance quality and cleanliness through polishing. Its core feature is to mirror or matte polish the joint after welding to remove the weld oxide layer, burrs and surface defects to improve corrosion resistance, hygiene and aesthetics. Stainless steel polished welded joints are mainly used in pipeline systems with high requirements for hygiene, corrosion resistance and cleanliness. They are usually installed in key connection positions such as pipe bends, branches, reducers or equipment interfaces to ensure sealing, smoothness and meet high standards of hygiene and corrosion resistance. The common types of stainless steel polished welded joints are as follows: flat welded joints, butt welded joints, flange welded joints, and clamp welded joints.

JONENG

8421219990

Stainless Steel Polished Weld on Male Pipe Ferrule Fitting

The main purpose of the design of stainless steel polished welded joints is to provide extremely high surface finish and cleanliness while ensuring structural strength to meet the needs of special environments. Its uses include high-purity fluid delivery systems (such as ultrapure water pipelines in semiconductor manufacturing) and sterile environments (such as biopharmaceutical equipment). Polishing reduces surface roughness, prevents contaminants from attaching or bacteria from growing, and ensures the purity of the medium and the reliability of equipment operation. Polishing can eliminate the surface roughness, oxide layer and impurities generated during welding, making the joint surface smooth and flat, reducing the accumulation of dirt and bacteria, and facilitating cleaning and maintenance.

Working Principles

The working principle of stainless steel polished welded joints is to achieve high strength, high sealing and high surface quality of pipeline connection through the combination of welding and polishing processes. Its working steps mainly include: first, the stainless steel pipes or components are precisely butted together through welding technologies such as argon arc welding and laser welding to form a firm weld; then, the welded joints are polished to remove the oxide layer, burrs and unevenness on the surface; then, multi-level polishing is performed using a polishing wheel or polishing liquid to gradually improve the surface finish to achieve a mirror effect; finally, the surface is cleaned to remove polishing residues to ensure that the joints are smooth and pollution-free.

The options for stainless steel polished welded joints include:

Material: 304 or 316L stainless steel, suitable for different corrosive environments.

Polishing level: mirror polishing, matte polishing, to meet different hygiene requirements.

Connection method: butt welding, plug welding, flange welding, etc.

Size: can be customized according to pipe diameter and wall thickness.

Sealing type: flat seal, O-ring seal, polytetrafluoroethylene (PTFE) seal, etc.

Surface treatment: electrolytic polishing, mechanical polishing, sandblasting, etc.

Connector type: tee, elbow, straight, flange, etc.

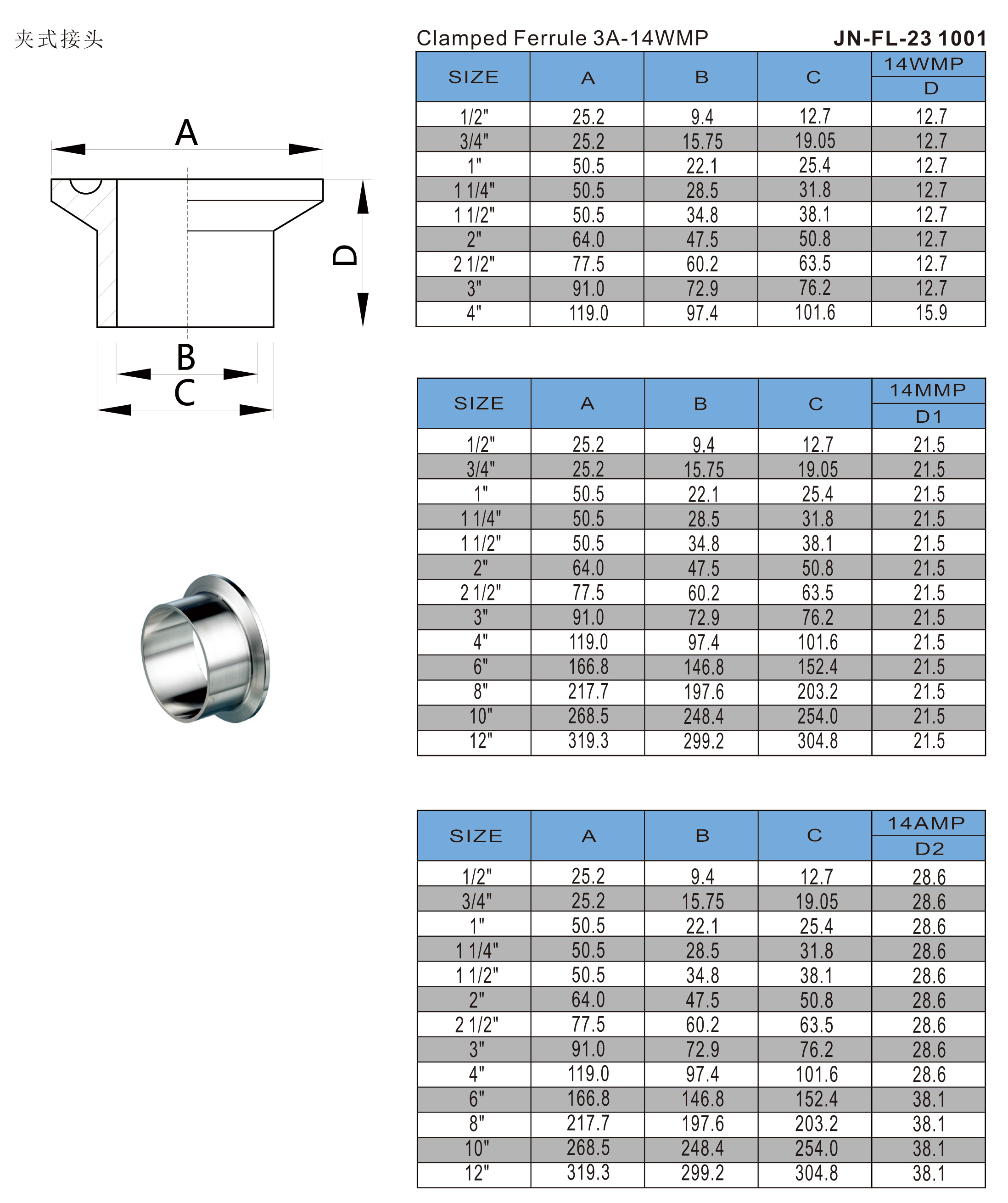

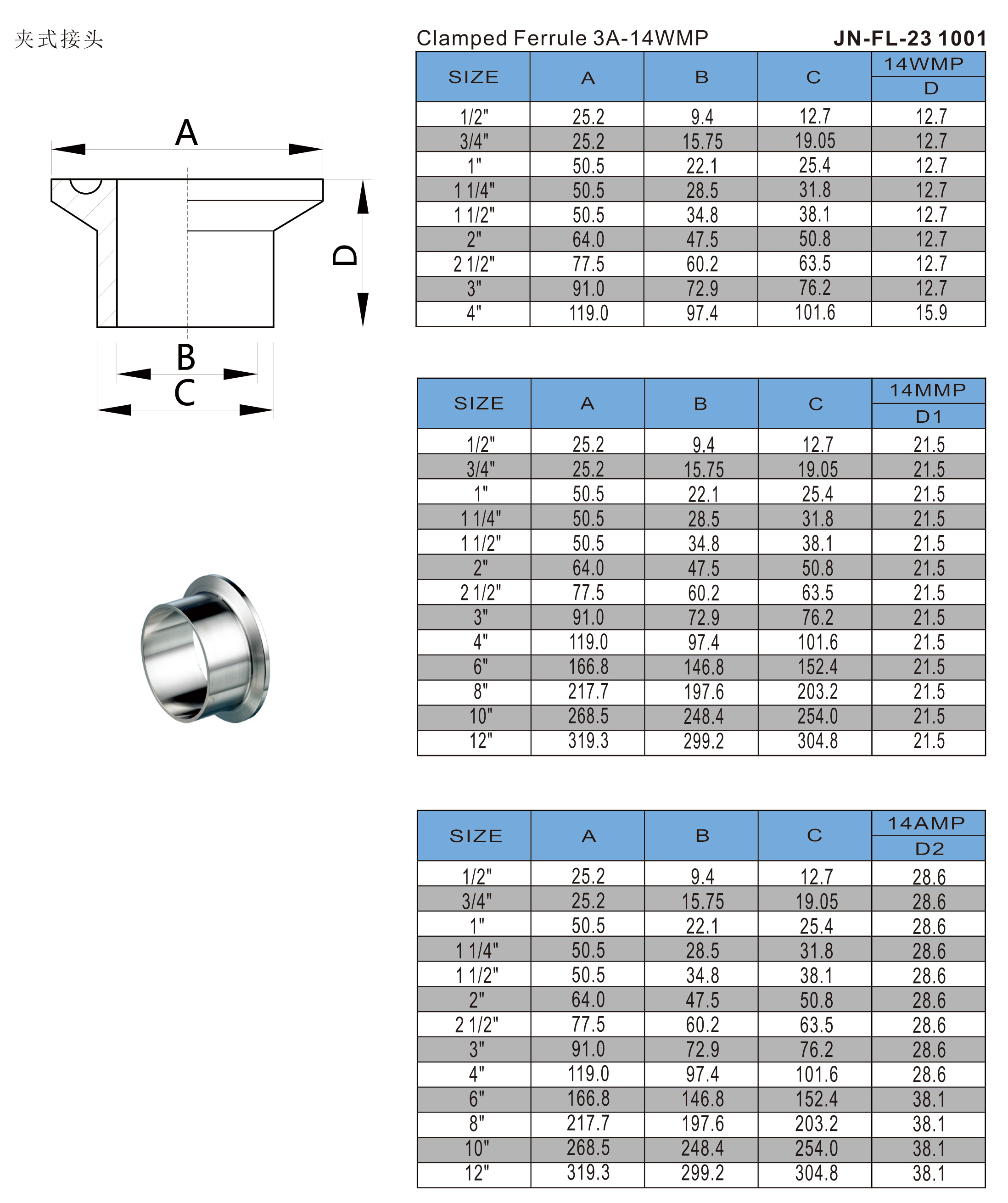

Specification Chart

Material | ASI304, 316L |

Size | ½ “ to 12” |

Gaskets or seals | Silicone, EPDM, Viton,NBR.. |

Pressure | 6 to 20 bars |

Temperature | 20C to 150C |

Standard | SMS, DIN, 3A,RJT,BSM,IDF.. |

Features

● Stainless steel polished welded joints use laser welding technology to precisely control heat input, combined with a post-surface polishing process to reduce the heat-affected zone.

● Stainless steel polished welded joints use extremely fine-grained metal welding filler materials for welding to reduce the formation of microcracks in the weld.

● Stainless steel polished welded joints apply a special thermal diffusion coating on the surface of the welded joint to ensure that the joint does not lose strength in a high-temperature environment.

● Stainless steel polished welded joints use titanium alloy fillers during welding to improve the corrosion resistance and wear resistance of the joint, and are particularly suitable for highly corrosive fluids.

● Stainless steel polished welded joints use electrochemical grinding technology for post-weld joint treatment to remove tiny surface impurities and improve smoothness.

● Stainless steel polished welded joints optimize the welding path design to ensure uniform distribution of welding heat, reduce local overheating and stress concentration.

Application

Stainless steel polished welded joints are used in the following industries, food industry: used in production lines such as juice, dairy products, and condiments to ensure that the pipeline is pollution-free and meets high hygiene standards. Pharmaceutical industry: used to transport liquid medicine and raw materials in the process of drug production, in compliance with GMP certification requirements to ensure no pollution. Cosmetic industry: used to transport cosmetic raw materials and finished products to prevent microbial contamination and maintain product quality. Beverage industry: used in the production process of beverages, beer, etc. to ensure sterility and not damage the quality of liquids. Chemical industry: used to transport chemical raw materials, solvents, acid and alkali solutions, etc. to prevent chemical corrosion and material leakage. Bioengineering: used to transport sterile fluids in the process of biopharmaceuticals and fermentation to ensure product safety.

Working Principles

Although the basic idea is rather simple but extremely powerful. It produces a mechanical grip that holds the components together by the ferrule around the component. Depending on the use and the kind of components being linked.

Specification Chart

Material | ASI304, 316L |

Size | ½ “ to 12” |

Gaskets or seals | Silicone, EPDM, Viton,NBR.. |

Pressure | 6 to 20 bars |

Temperature | 20C to 150C |

Standard | SMS, DIN, 3A,RJT,BSM,IDF.. |

Features

●Leak resistance, flexibility

●Ease of installation

●Forged from sheets as raw material

●Machined from forged raw materials

●Hygienic design, leak free connections

●Easy disassembly

●High precise roughness produced from CNC machine

●High precise dimensions , without human error

Application

These are commonly used in various industries where reliable and leak free connections are essential like plumbing, instrumentation and cable assemblies, automotive industries, hydraulic and pneumatic system and others.