| Availability: | |

|---|---|

| Quantity: | |

JN-FT-23 5017

JONENG

7307290000

Stainless Steel Hygiene And Other Diameter Welding Tee For Cosmetics

The design of stainless steel sanitary welding tees is not only for simple fluid diversion or confluence, but also to meet the process needs of high cleanliness, pollution-free and efficient transportation. It eliminates the possible leakage hazards and cleaning blind spots caused by traditional connection methods through welding connections, ensuring that the hygiene standards of the entire pipeline system meet strict industry requirements. Its interior has been polished to keep the fluid flowing smoothly on the inner wall of the pipeline, avoiding deposition and microbial growth, and is especially suitable for biopharmaceuticals, electronic chemicals and high-end food manufacturing. In addition, it can optimize fluid dynamics, reduce pressure losses, improve delivery efficiency, and support CIP/SIP cleaning and sterilization to ensure the sustained stability of the production environment.

Working Principles

The working principle of stainless steel sanitary welding tees is based on the need to divert, merge or change the flow direction of fluid in the pipeline. The working process includes the following steps: First, the welding tee is connected to the pipeline system through welding to form a seamless and blind-angle-free pipeline structure to ensure hygiene requirements. Secondly, when the fluid enters the main pipe, according to the design requirements, the fluid can be evenly diverted to the two branch pipes, or the fluid of the two branch pipes is merged into the main pipe to achieve reasonable distribution of flow. The internal precision polished tube wall reduces flow resistance and prevents media retention or contaminants from adhering, thereby optimizing fluid dynamics.

Options for stainless steel sanitary welded tees include:

Specification and size: Different pipe diameters are available (such as DN25-DN150).

Structural types: equal diameter, reduce diameter, Y-shaped, 45°, 90°, etc.

Surface treatment: Inner and outer polishing Ra≤0.8μm or higher hygiene level.

Material selection: 304, 316L, etc., to meet different working conditions.

Wall thickness is optional: Different pressure levels can choose the appropriate wall thickness.

Sealing compatibility: adapts to CIP/SIP cleaning requirements to avoid residue.

Customized interface: optional flange, quick loading, threading and other connection methods.

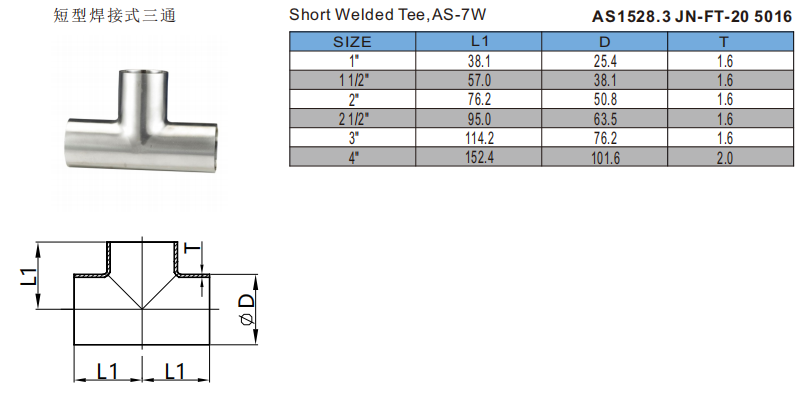

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The stainless steel sanitary welded tee uses computational fluid mechanics (CFD) simulation to optimize the internal runner, so that the flow distribution of the three interfaces is uneven but the pressure loss is minimized, and turbulence and blind spots are avoided.

● After the welding is completed, the stainless steel sanitary welding tee is used to coat ultra-fine stainless steel powder on the surface of the weld to form a nanocrystalline structure layer to improve the weld's resistance to intergranular corrosion.

● After welding of stainless steel sanitary welding, the tee is subjected to high-frequency mechanical vibration treatment to redistribute the residual stress and reduce it by more than 30%, avoiding fatigue cracks under long-term pulse pressure.

● Stainless steel sanitary welding tee is superimposed on traditional electrolytic polishing to reduce the inner surface roughness to Ra≤0.1μm, and the thickness uniformity of the passivation film is increased by 50%.

● When welding sanitary welding of stainless steel, infrared thermal imager is used to monitor the temperature of the heat-affected zone in real time, and dynamically adjust the argon protection flow through the PID algorithm.

● Stainless steel sanitary welding tee pre-installs a nickel-based alloy transition layer between the 316L matrix and the weld, forming a gradient metallurgical combination through diffusion welding to solve the problem of galvanic corrosion during different types of pipe connections.

Application

Stainless steel sanitary welding tees are widely used in the following industries: Food and beverage industry: used for fluid transportation such as dairy products, juices, beer, pure water, etc. Pharmaceutical industry: Suitable for sterile delivery systems and meet GMP requirements. Biotechnology: used in vaccines, fermentation, laboratory high and clean pipeline systems. Cosmetics industry: such as skin care products, fragrance and fragrance production pipeline. Chemical industry: used for high-demand fluid delivery, such as fine chemicals, electronic chemicals. Dairy processing: applied in pasteurization, milk powder, yogurt and other production processes.

Working Principles

The working principle of stainless steel sanitary welding tees is based on the need to divert, merge or change the flow direction of fluid in the pipeline. The working process includes the following steps: First, the welding tee is connected to the pipeline system through welding to form a seamless and blind-angle-free pipeline structure to ensure hygiene requirements. Secondly, when the fluid enters the main pipe, according to the design requirements, the fluid can be evenly diverted to the two branch pipes, or the fluid of the two branch pipes is merged into the main pipe to achieve reasonable distribution of flow. The internal precision polished tube wall reduces flow resistance and prevents media retention or contaminants from adhering, thereby optimizing fluid dynamics.

Options for stainless steel sanitary welded tees include:

Specification and size: Different pipe diameters are available (such as DN25-DN150).

Structural types: equal diameter, reduce diameter, Y-shaped, 45°, 90°, etc.

Surface treatment: Inner and outer polishing Ra≤0.8μm or higher hygiene level.

Material selection: 304, 316L, etc., to meet different working conditions.

Wall thickness is optional: Different pressure levels can choose the appropriate wall thickness.

Sealing compatibility: adapts to CIP/SIP cleaning requirements to avoid residue.

Customized interface: optional flange, quick loading, threading and other connection methods.

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The stainless steel sanitary welded tee uses computational fluid mechanics (CFD) simulation to optimize the internal runner, so that the flow distribution of the three interfaces is uneven but the pressure loss is minimized, and turbulence and blind spots are avoided.

● After the welding is completed, the stainless steel sanitary welding tee is used to coat ultra-fine stainless steel powder on the surface of the weld to form a nanocrystalline structure layer to improve the weld's resistance to intergranular corrosion.

● After welding of stainless steel sanitary welding, the tee is subjected to high-frequency mechanical vibration treatment to redistribute the residual stress and reduce it by more than 30%, avoiding fatigue cracks under long-term pulse pressure.

● Stainless steel sanitary welding tee is superimposed on traditional electrolytic polishing to reduce the inner surface roughness to Ra≤0.1μm, and the thickness uniformity of the passivation film is increased by 50%.

● When welding sanitary welding of stainless steel, infrared thermal imager is used to monitor the temperature of the heat-affected zone in real time, and dynamically adjust the argon protection flow through the PID algorithm.

● Stainless steel sanitary welding tee pre-installs a nickel-based alloy transition layer between the 316L matrix and the weld, forming a gradient metallurgical combination through diffusion welding to solve the problem of galvanic corrosion during different types of pipe connections.

Application

Stainless steel sanitary welding tees are widely used in the following industries: Food and beverage industry: used for fluid transportation such as dairy products, juices, beer, pure water, etc. Pharmaceutical industry: Suitable for sterile delivery systems and meet GMP requirements. Biotechnology: used in vaccines, fermentation, laboratory high and clean pipeline systems. Cosmetics industry: such as skin care products, fragrance and fragrance production pipeline. Chemical industry: used for high-demand fluid delivery, such as fine chemicals, electronic chemicals. Dairy processing: applied in pasteurization, milk powder, yogurt and other production processes.