| Availability: | |

|---|---|

| Quantity: | |

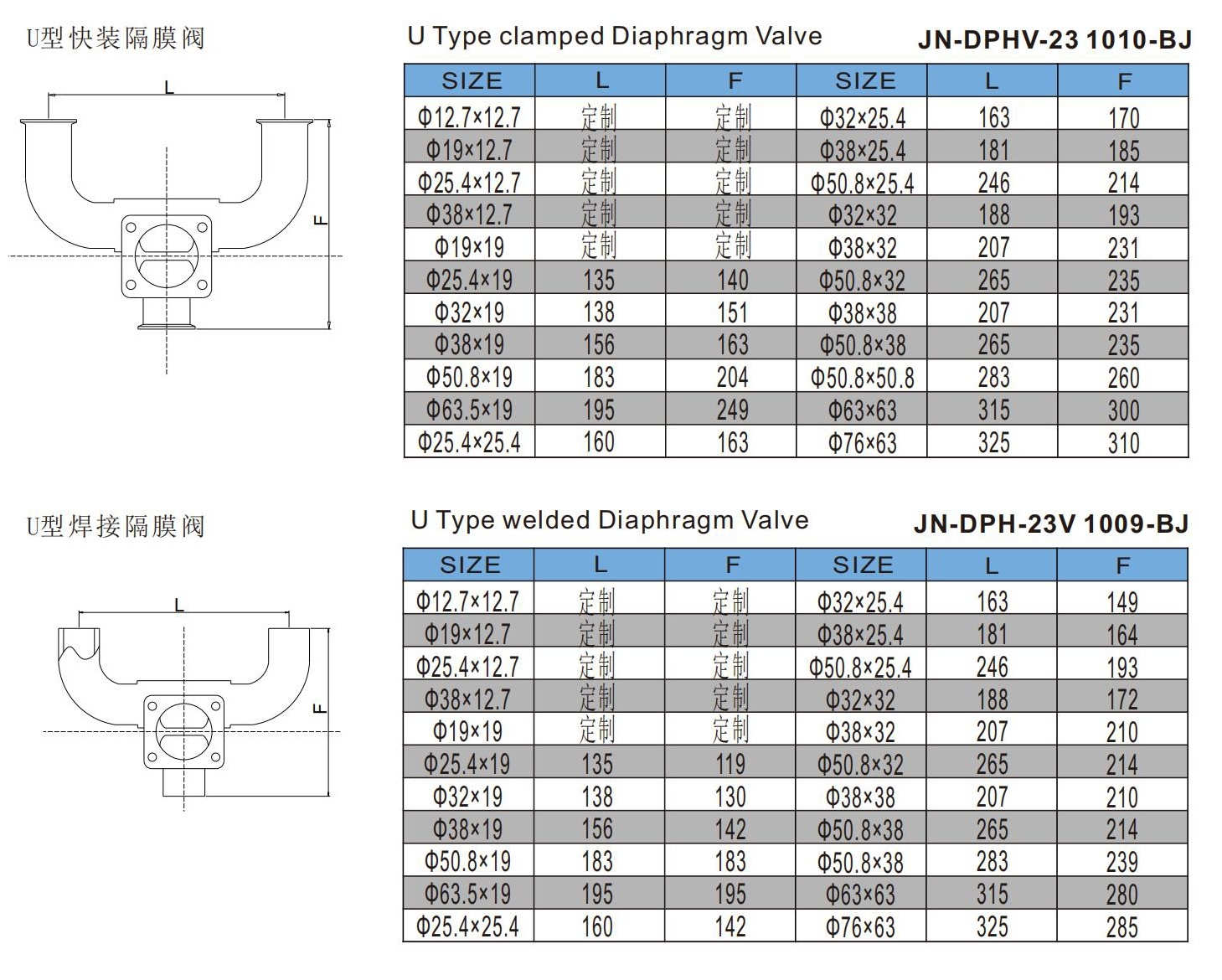

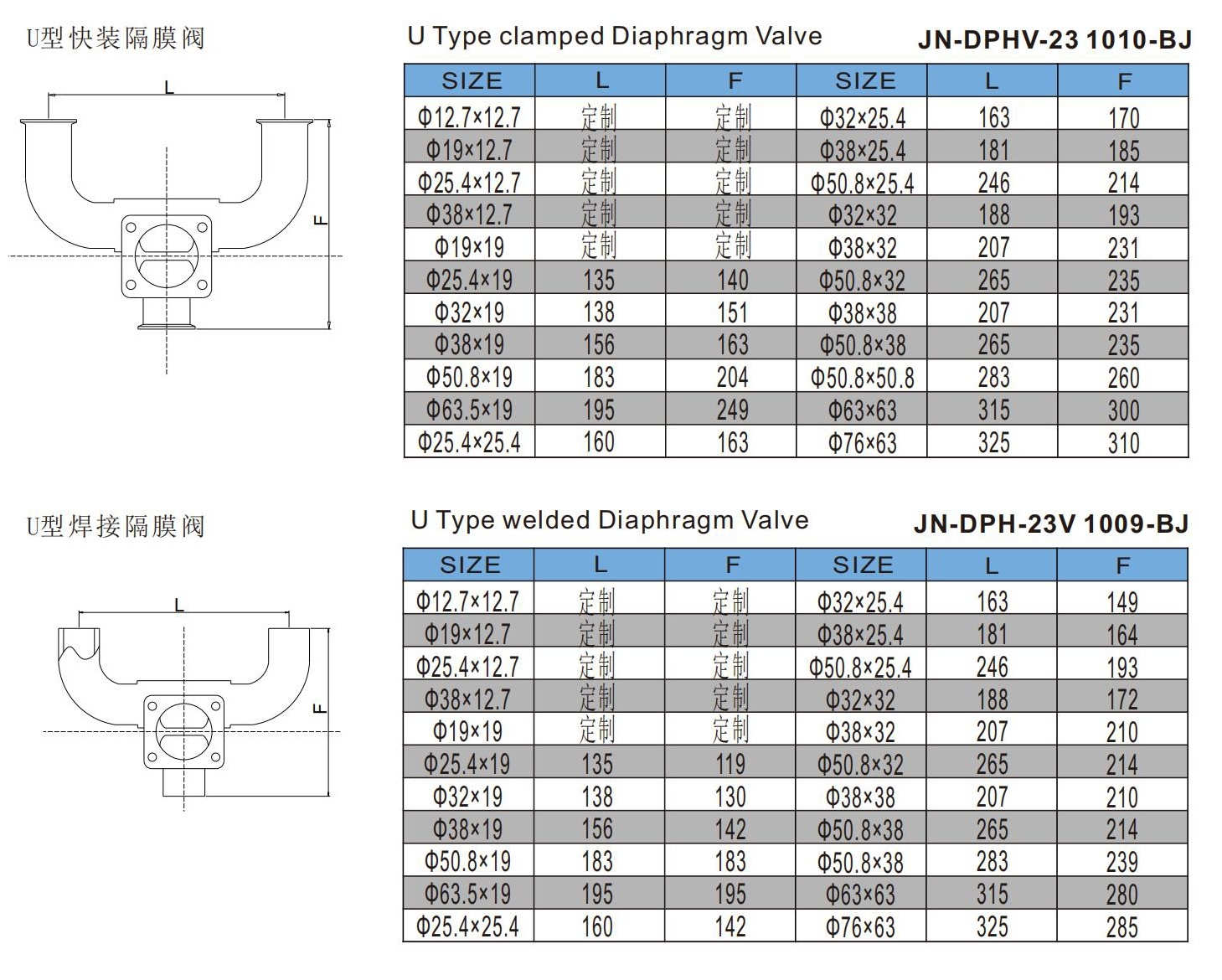

JN-DPHV-23 1010-BJ

JONENG

8481804090

Stainless Steel Sanitary Butt Weld Zero Static U-type Diaphragm Valve

The design of the stainless steel sanitary U-type diaphragm valve is mainly to solve the problem that traditional valves are easy to foul and difficult to clean in industries with high sanitation requirements. The unique design of the U-shaped structure ensures smooth flow inside the valve body, reduces fluid retention and dead corners, and effectively avoids the growth of pollutants and microorganisms. It provides perfect sealing through the built-in diaphragm, which not only prevents leakage, but also improves the control accuracy of the fluid. The design of this valve not only ensures high sanitation standards, but also has a longer service life, reduces the need for frequent maintenance and replacement, and is very suitable for food, pharmaceutical and other industries.

Working Principles

The working principle of the stainless steel sanitary U-type diaphragm valve is based on the deformation of the diaphragm and the structural coordination of the valve body. A U-shaped valve body and a flexible diaphragm are provided inside the valve. When the valve is opened, the fluid enters the pipeline through the valve seat, and the diaphragm bends outward, allowing the fluid to pass freely. When closed, the operating handle or actuator drives the diaphragm to compress inward, tightly fitting the valve seat, thereby cutting off the flow of the fluid.

The use of stainless steel sanitary U-type diaphragm valve effectively isolates the fluid from the inner cavity of the valve, avoids corrosion and fouling, and maintains the cleanliness of the fluid.

The options of stainless steel sanitary U-type diaphragm valve include:

Drive mode: manual, pneumatic, electric.

Diaphragm material: rubber, silicone, PTFE, etc.

Connection mode: quick-install, threaded, welded.

Valve body type: single diaphragm, double diaphragm design.

Valve size: different sizes can be selected according to the size of the pipeline.

Sealing level: sealing performance required by different hygiene standards.

Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

● The stainless steel sanitary U-type diaphragm valve adopts a unique U-type valve body structure, which optimizes the fluid flow path, reduces fluid retention and dead zones, and improves the flow efficiency of the fluid.

● The stainless steel sanitary U-type diaphragm valve is equipped with a double-layer diaphragm system, with an auxiliary diaphragm outside the main diaphragm to enhance the sealing and protection.

● The stainless steel sanitary U-type diaphragm valve body design avoids the dead zone through which the fluid flows, ensuring that the fluid will not accumulate or stagnate during the passage.

● The stainless steel sanitary U-type diaphragm valve seat and valve body are integrated to avoid the problem of easy loosening and leakage of the traditional valve seat.

● The stainless steel sanitary U-type diaphragm valve is equipped with precise adjustment components and sealing rings, which can accurately adjust the fluid flow and control the flow rate.

● The diaphragm design in the stainless steel sanitary U-type diaphragm valve is highly sensitive to pressure changes and can quickly respond to changes in fluid state.

Application

Stainless steel sanitary U-type diaphragm valves are widely used in the following industries: Food processing industry: ensure fluid cleanliness and meet food hygiene standards. Pharmaceutical industry: prevent pollution and ensure a sterile environment for drug production. Beverage production industry: ensure the pure circulation of beverage raw materials. Cosmetic industry: prevent impurities from entering the production process to ensure quality. Biopharmaceutical industry: adapt to high-precision fluid control and prevent cross contamination. Dairy processing: Ensure hygiene and flow control during dairy production. Chemical industry: Used for fluid switching control during chemical reactions.

Working Principles

The working principle of the stainless steel sanitary U-type diaphragm valve is based on the deformation of the diaphragm and the structural coordination of the valve body. A U-shaped valve body and a flexible diaphragm are provided inside the valve. When the valve is opened, the fluid enters the pipeline through the valve seat, and the diaphragm bends outward, allowing the fluid to pass freely. When closed, the operating handle or actuator drives the diaphragm to compress inward, tightly fitting the valve seat, thereby cutting off the flow of the fluid.

The use of stainless steel sanitary U-type diaphragm valve effectively isolates the fluid from the inner cavity of the valve, avoids corrosion and fouling, and maintains the cleanliness of the fluid.

The options of stainless steel sanitary U-type diaphragm valve include:

Drive mode: manual, pneumatic, electric.

Diaphragm material: rubber, silicone, PTFE, etc.

Connection mode: quick-install, threaded, welded.

Valve body type: single diaphragm, double diaphragm design.

Valve size: different sizes can be selected according to the size of the pipeline.

Sealing level: sealing performance required by different hygiene standards.

Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

● The stainless steel sanitary U-type diaphragm valve adopts a unique U-type valve body structure, which optimizes the fluid flow path, reduces fluid retention and dead zones, and improves the flow efficiency of the fluid.

● The stainless steel sanitary U-type diaphragm valve is equipped with a double-layer diaphragm system, with an auxiliary diaphragm outside the main diaphragm to enhance the sealing and protection.

● The stainless steel sanitary U-type diaphragm valve body design avoids the dead zone through which the fluid flows, ensuring that the fluid will not accumulate or stagnate during the passage.

● The stainless steel sanitary U-type diaphragm valve seat and valve body are integrated to avoid the problem of easy loosening and leakage of the traditional valve seat.

● The stainless steel sanitary U-type diaphragm valve is equipped with precise adjustment components and sealing rings, which can accurately adjust the fluid flow and control the flow rate.

● The diaphragm design in the stainless steel sanitary U-type diaphragm valve is highly sensitive to pressure changes and can quickly respond to changes in fluid state.

Application

Stainless steel sanitary U-type diaphragm valves are widely used in the following industries: Food processing industry: ensure fluid cleanliness and meet food hygiene standards. Pharmaceutical industry: prevent pollution and ensure a sterile environment for drug production. Beverage production industry: ensure the pure circulation of beverage raw materials. Cosmetic industry: prevent impurities from entering the production process to ensure quality. Biopharmaceutical industry: adapt to high-precision fluid control and prevent cross contamination. Dairy processing: Ensure hygiene and flow control during dairy production. Chemical industry: Used for fluid switching control during chemical reactions.