| Availability: | |

|---|---|

| Quantity: | |

JN SV 1075

JONENG

8481804090

Stainless Steel Sanitary DN15 Spherical Pressure Relief Safety Valve

The stainless steel sanitary spherical safety valve can effectively prevent the pipeline system from bursting or malfunctioning due to excessive pressure. It quickly releases excess pressure through a precise switching mechanism to avoid damage to equipment and pipelines. In addition, the spherical design optimizes the fluid flow path and reduces fluid resistance, thereby improving the overall stability and efficiency of the system. It also ensures that the system operates stably under strict hygienic requirements, is suitable for high-cleanliness environments, and ensures aseptic production and safe delivery of fluids.

Working Principles

The working principle of the stainless steel sanitary ball safety valve is to set the opening pressure through an internal spring or pneumatic control mechanism. When the pressure in the pipeline exceeds the preset value, the valve core overcomes the resistance of the spring or drive device under the action of pressure and quickly opens to release excess pressure. After the system pressure returns to normal, the spring or drive mechanism automatically returns the valve core and seals the valve port to ensure the safe and stable operation of the pipeline system. Using a stainless steel sanitary ball safety valve can avoid pollution, reduce maintenance requirements, and reduce long-term operating costs.

The options for stainless steel sanitary ball safety valves include:

Material selection: 304, 316L stainless steel, etc.

Sealing material: EPDM, PTFE, Viton, etc.

Opening method: spring type, pneumatic control type

Interface type: welding, quick installation, thread, flange

Pressure adjustment range: customizable set pressure

Surface treatment: mirror polishing, electrolytic polishing

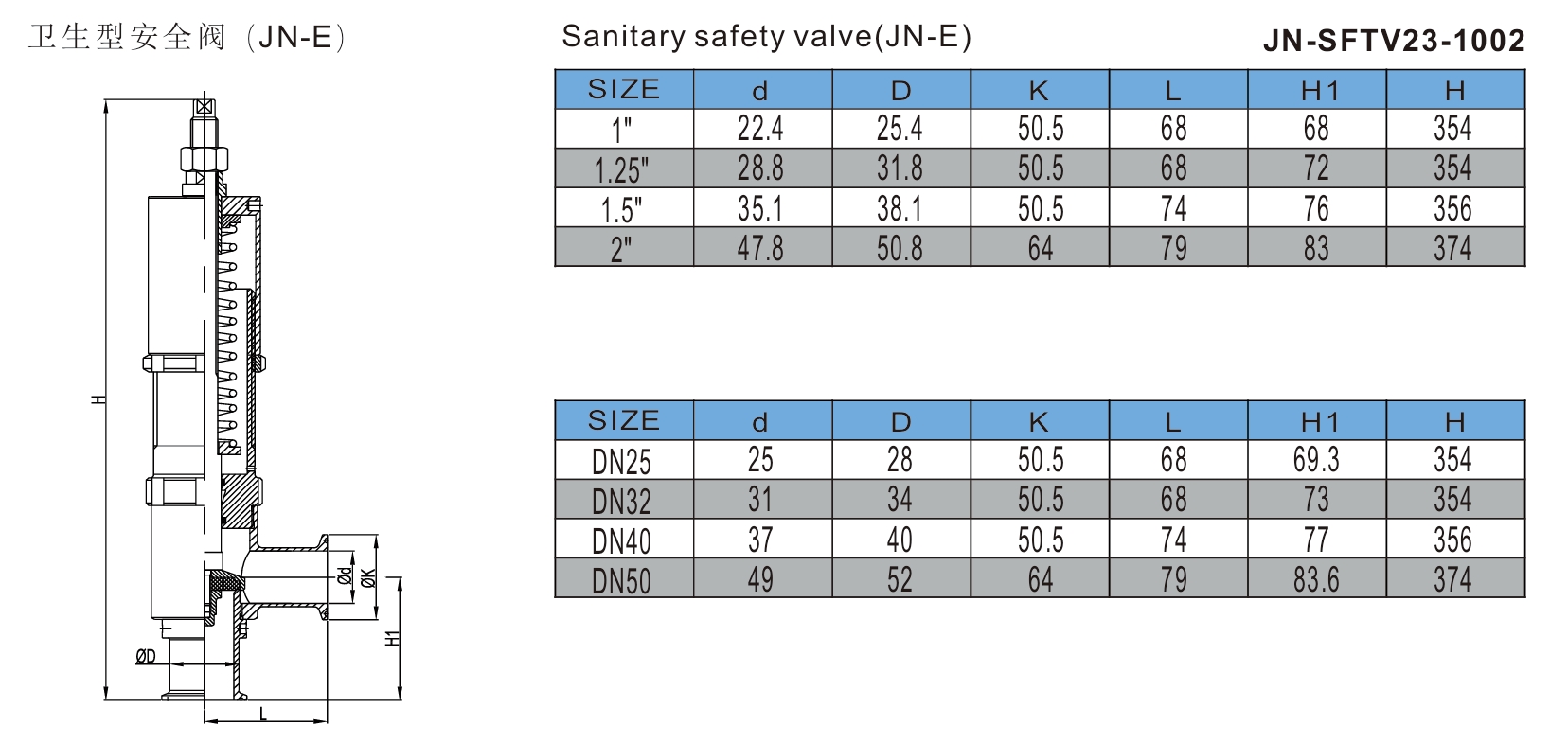

Specification Chart

Type | Ball type, line type |

Working Pressure | 0bar-10bar |

Working Temperature | -10°C ~ +121°C |

Connection end | welded,clamped , threaded, union type |

Connection Standards | DIN, SMS, 3A, ISO |

Size | 1”-4”, DN25-DN100 |

Material | SS304, SS316L from solid bar raw material |

| With internal finishing Ra16<0.4micron | |

Surface finish | Sand blasting type, or mirror type |

Seal Material | FDA approved EPDM, VITION, NBR, SILICOME |

| Adjusting pressure | 0.5bar/unit |

| Manually adjustable to keep the system safety | |

Lock can be available for settling the relief pressure | |

Features

● The spherical design of the stainless steel sanitary spherical safety valve provides a better fluid flow path, optimizes the valve switch response speed, and is suitable for high flow and high pressure environments.

● The stainless steel sanitary spherical safety valve uses a high-precision spring to adjust the pressure, ensuring that the safety valve is stably opened and closed at the set pressure, providing precise pressure control.

● Fluid guide and silencer devices are added to the design of the stainless steel sanitary spherical safety valve, which is suitable for noise-sensitive environments.

● The valve body of the stainless steel sanitary spherical safety valve adopts optimized fluid channels to quickly respond to pressure changes, prevent overpressure from damaging equipment, and improve system safety.

● The stainless steel sanitary spherical safety valve adopts two-way sealing technology to enhance sealing performance and is not affected by fluid flow direction.

● The stainless steel sanitary spherical safety valve uses internal design pressure balance to prevent false operation caused by temperature or pressure fluctuations, ensuring the reliability of the valve under extreme conditions.

Application

Stainless steel sanitary ball safety valves are widely used in the following industries: Pharmaceutical industry: used for pressure protection of pharmaceutical production equipment to ensure safe operation of the system. Food industry: used for food processing equipment to prevent safety accidents caused by overpressure. Biotechnology industry: protect the safety of equipment in the production process of biological products and avoid excessive pressure. Chemical industry: used for chemical reactors and other equipment to prevent safety risks caused by overpressure. Beverage industry: Ensure the pressure safety of equipment during beverage production to avoid explosion or leakage. Steam system: Used in steam boilers and piping systems to prevent overpressure from damaging equipment.

Working Principles

The working principle of the stainless steel sanitary ball safety valve is to set the opening pressure through an internal spring or pneumatic control mechanism. When the pressure in the pipeline exceeds the preset value, the valve core overcomes the resistance of the spring or drive device under the action of pressure and quickly opens to release excess pressure. After the system pressure returns to normal, the spring or drive mechanism automatically returns the valve core and seals the valve port to ensure the safe and stable operation of the pipeline system. Using a stainless steel sanitary ball safety valve can avoid pollution, reduce maintenance requirements, and reduce long-term operating costs.

The options for stainless steel sanitary ball safety valves include:

Material selection: 304, 316L stainless steel, etc.

Sealing material: EPDM, PTFE, Viton, etc.

Opening method: spring type, pneumatic control type

Interface type: welding, quick installation, thread, flange

Pressure adjustment range: customizable set pressure

Surface treatment: mirror polishing, electrolytic polishing

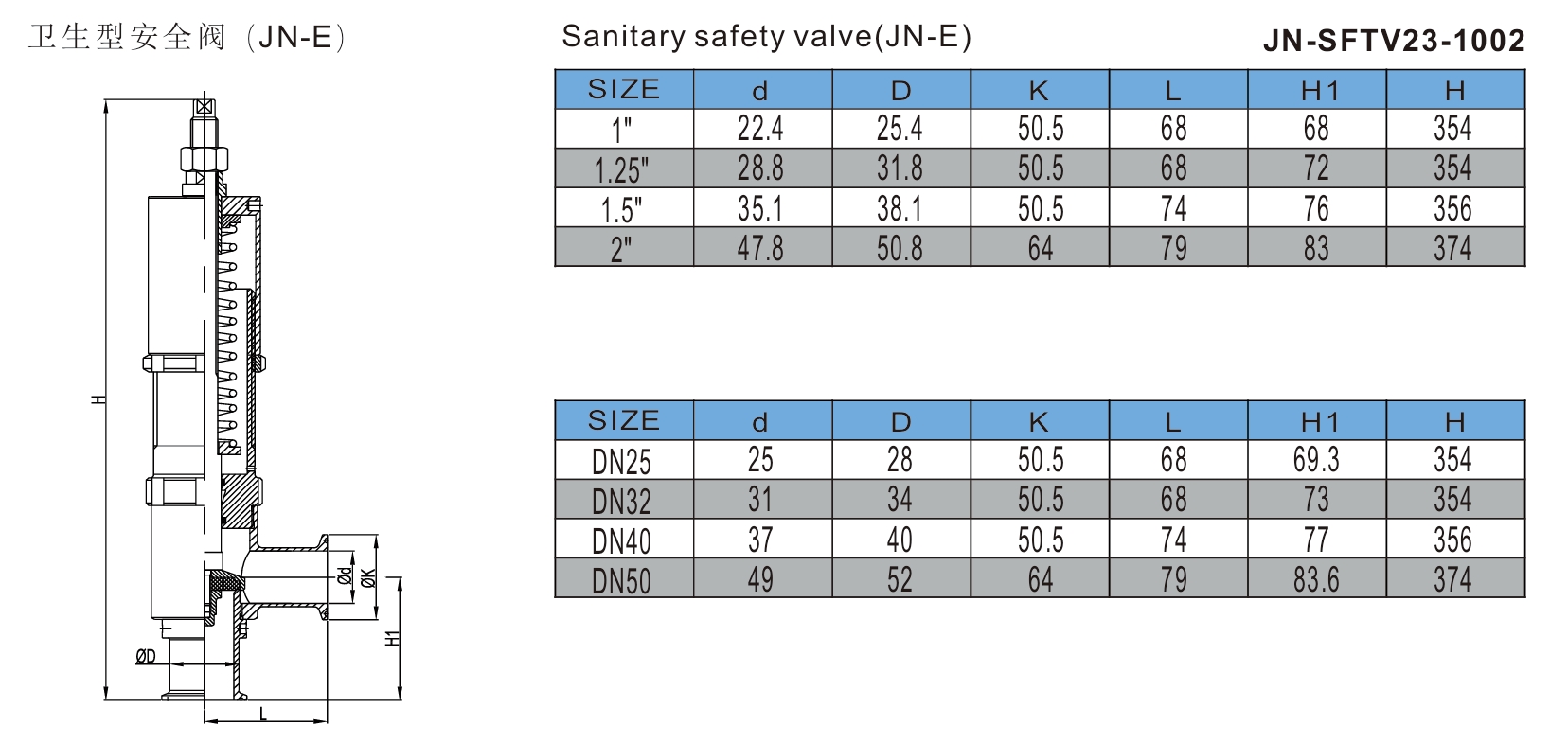

Specification Chart

Type | Ball type, line type |

Working Pressure | 0bar-10bar |

Working Temperature | -10°C ~ +121°C |

Connection end | welded,clamped , threaded, union type |

Connection Standards | DIN, SMS, 3A, ISO |

Size | 1”-4”, DN25-DN100 |

Material | SS304, SS316L from solid bar raw material |

| With internal finishing Ra16<0.4micron | |

Surface finish | Sand blasting type, or mirror type |

Seal Material | FDA approved EPDM, VITION, NBR, SILICOME |

| Adjusting pressure | 0.5bar/unit |

| Manually adjustable to keep the system safety | |

Lock can be available for settling the relief pressure | |

Features

● The spherical design of the stainless steel sanitary spherical safety valve provides a better fluid flow path, optimizes the valve switch response speed, and is suitable for high flow and high pressure environments.

● The stainless steel sanitary spherical safety valve uses a high-precision spring to adjust the pressure, ensuring that the safety valve is stably opened and closed at the set pressure, providing precise pressure control.

● Fluid guide and silencer devices are added to the design of the stainless steel sanitary spherical safety valve, which is suitable for noise-sensitive environments.

● The valve body of the stainless steel sanitary spherical safety valve adopts optimized fluid channels to quickly respond to pressure changes, prevent overpressure from damaging equipment, and improve system safety.

● The stainless steel sanitary spherical safety valve adopts two-way sealing technology to enhance sealing performance and is not affected by fluid flow direction.

● The stainless steel sanitary spherical safety valve uses internal design pressure balance to prevent false operation caused by temperature or pressure fluctuations, ensuring the reliability of the valve under extreme conditions.

Application

Stainless steel sanitary ball safety valves are widely used in the following industries: Pharmaceutical industry: used for pressure protection of pharmaceutical production equipment to ensure safe operation of the system. Food industry: used for food processing equipment to prevent safety accidents caused by overpressure. Biotechnology industry: protect the safety of equipment in the production process of biological products and avoid excessive pressure. Chemical industry: used for chemical reactors and other equipment to prevent safety risks caused by overpressure. Beverage industry: Ensure the pressure safety of equipment during beverage production to avoid explosion or leakage. Steam system: Used in steam boilers and piping systems to prevent overpressure from damaging equipment.