| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary single-seat double-seal anti-mix valve is a high-efficiency anti-mix valve designed for the sanitary industry. It adopts a single-seat structure to prevent the cross-mixing of fluids inside the valve. The purpose of the stainless steel sanitary single-seat double-seal anti-mix valve is mainly used for flow control and distribution of liquids or gases, ensuring the diversion and isolation of different substances and preventing cross-contamination of different media. The stainless steel sanitary single-seat double-seal anti-mix valve is usually installed at key control points of sanitary pipelines, such as diversion, confluence or switching positions. Common types of stainless steel sanitary single-seat double-seal anti-mix valves include: straight-through single-seat double-seal anti-mix valve, angle single-seat double-seal anti-mix valve, electric single-seat double-seal anti-mix valve, pneumatic single-seat double-seal anti-mix valve, and manual single-seat double-seal anti-mix valve.

JONENG

8481804090

Stainless Steel Sanitary EPDM Electric Welded Mixproof Valve For Food

The main purpose of the design of the stainless steel sanitary single-seat double-seal anti-mix valve is to ensure that during the fluid control process, cross-contamination of different media is prevented and the sanitary requirements of the pipeline system are maintained. It effectively isolates different fluids through a unique double-seal structure, avoids mixing caused by poor valve sealing or valve body design problems, and ensures the purity of each fluid. This design is widely used in industries that require strict hygiene standards, such as food, beverages, pharmaceuticals, etc. It not only improves the safety of the system, but also reduces the cost of cleaning and maintenance, and extends the service life of the equipment.

Working Principles

The working principle of the stainless steel sanitary single-seat double-seal anti-mixing valve is based on a double-seal structure to prevent cross-contamination of different media. First, the valve controls the rise and fall of the valve core through an actuator (electric or pneumatic) to adjust the passage of the fluid. When the fluid passes through the valve seat, it first contacts the inner seal ring to prevent fluid leakage or mixing. As the valve core moves, the outer seal ring further ensures the isolation of the fluid from other fluids and ensures the reliability of the seal. By precisely adjusting the opening of the valve core, the flow rate can be accurately controlled and the fluid can be effectively distributed, while preventing cross-contamination of different media through the valve.

The options of the stainless steel sanitary single-seat double-seal anti-mixing valve include:

Size: A variety of pipe diameters are available.

Connection method: welding, clamp, thread, etc.

Sealing material: EPDM, PTFE, Viton, etc.

Drive method: manual, electric, pneumatic.

Valve body material: 304, 316L stainless steel.

Temperature range: suitable for different temperature environments.

Pressure level: suitable for different pressure requirements.

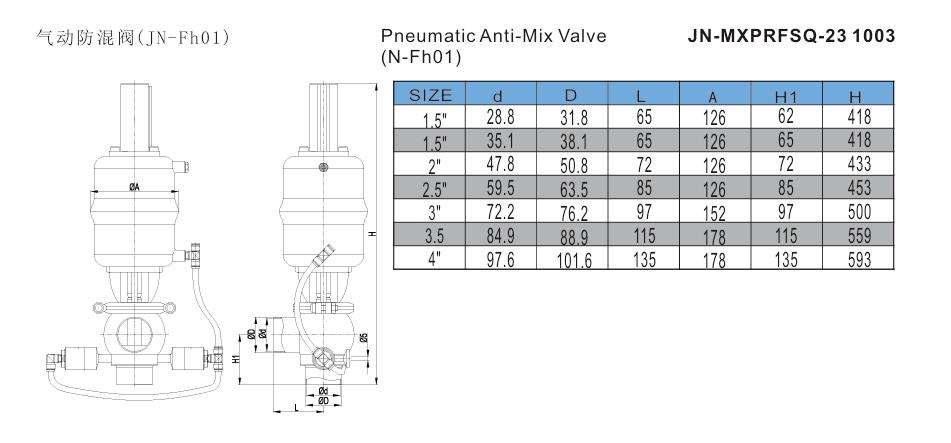

Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 8 bar pressure |

Max temperature | -20 °C to 150 °C |

Seals | EPDM, NBR, PTFE |

End connections | Welded, threaded, clamped, flanged |

Seals | PTFE, EPDM, NBR |

Features

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts an internal and external double-seal structure. The inner seal is responsible for the initial isolation of the fluid, while the outer seal further prevents leakage or cross contamination.

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts a self-cleaning valve seat design, which can automatically remove surface deposits when the valve is switched, avoiding the appearance of sanitary dead corners.

● The stainless steel sanitary single-seat double-seal anti-mixing valve has a high-temperature resistant sealing ring and a high-temperature resistant valve body material, which enables it to work stably in a high-temperature environment and avoid damage to the valve by high-temperature fluids.

● The stainless steel sanitary single-seat double-seal anti-mixing valve body is equipped with a pressure balancing device, which can effectively alleviate the impact caused by pressure fluctuations.

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts a low-friction bearing design, and the valve core can move more smoothly during the switching process.

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts an all-metal heat exchange structure inside, which effectively improves the heat transfer efficiency.

Application

Stainless steel sanitary single-seat double-seal anti-mixing valve is widely used in the following industries: Food industry: used to prevent mixing of different raw materials to ensure product quality. Beverage industry: control fluid distribution, prevent cross contamination, and ensure hygiene standards. Pharmaceutical industry: used to accurately control the flow of drug ingredients to avoid cross contamination. Cosmetic industry: used for high-precision fluid control to keep the product pure. Dairy industry: prevent dairy products from mixing to ensure product hygiene and safety. Chemical industry: isolate different chemical fluids to prevent reactions and contamination. Biological agent industry: ensure a clean production environment to avoid cross-contamination of biological components.

Working Principles

The working principle of the stainless steel sanitary single-seat double-seal anti-mixing valve is based on a double-seal structure to prevent cross-contamination of different media. First, the valve controls the rise and fall of the valve core through an actuator (electric or pneumatic) to adjust the passage of the fluid. When the fluid passes through the valve seat, it first contacts the inner seal ring to prevent fluid leakage or mixing. As the valve core moves, the outer seal ring further ensures the isolation of the fluid from other fluids and ensures the reliability of the seal. By precisely adjusting the opening of the valve core, the flow rate can be accurately controlled and the fluid can be effectively distributed, while preventing cross-contamination of different media through the valve.

The options of the stainless steel sanitary single-seat double-seal anti-mixing valve include:

Size: A variety of pipe diameters are available.

Connection method: welding, clamp, thread, etc.

Sealing material: EPDM, PTFE, Viton, etc.

Drive method: manual, electric, pneumatic.

Valve body material: 304, 316L stainless steel.

Temperature range: suitable for different temperature environments.

Pressure level: suitable for different pressure requirements.

Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 8 bar pressure |

Max temperature | -20 °C to 150 °C |

Seals | EPDM, NBR, PTFE |

End connections | Welded, threaded, clamped, flanged |

Seals | PTFE, EPDM, NBR |

Features

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts an internal and external double-seal structure. The inner seal is responsible for the initial isolation of the fluid, while the outer seal further prevents leakage or cross contamination.

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts a self-cleaning valve seat design, which can automatically remove surface deposits when the valve is switched, avoiding the appearance of sanitary dead corners.

● The stainless steel sanitary single-seat double-seal anti-mixing valve has a high-temperature resistant sealing ring and a high-temperature resistant valve body material, which enables it to work stably in a high-temperature environment and avoid damage to the valve by high-temperature fluids.

● The stainless steel sanitary single-seat double-seal anti-mixing valve body is equipped with a pressure balancing device, which can effectively alleviate the impact caused by pressure fluctuations.

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts a low-friction bearing design, and the valve core can move more smoothly during the switching process.

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts an all-metal heat exchange structure inside, which effectively improves the heat transfer efficiency.

Application

Stainless steel sanitary single-seat double-seal anti-mixing valve is widely used in the following industries: Food industry: used to prevent mixing of different raw materials to ensure product quality. Beverage industry: control fluid distribution, prevent cross contamination, and ensure hygiene standards. Pharmaceutical industry: used to accurately control the flow of drug ingredients to avoid cross contamination. Cosmetic industry: used for high-precision fluid control to keep the product pure. Dairy industry: prevent dairy products from mixing to ensure product hygiene and safety. Chemical industry: isolate different chemical fluids to prevent reactions and contamination. Biological agent industry: ensure a clean production environment to avoid cross-contamination of biological components.