| Availability: | |

|---|---|

| Quantity: | |

JN-BV 1007

JONENG

8481804090

Stainless Steel Sanitary Food Grade Vibrating Manual Butterfly Valve

The stainless steel sanitary duckbill manual butterfly valve is designed to meet the complex needs of high hygiene standards and precise flow control. Its duckbill shape design ensures that a tighter seal can be formed when the fluid is closed, reducing the possibility of fluid backflow and leakage, and is particularly suitable for handling high-viscosity liquids or fluids containing particles. Through manual adjustment operations, the flow rate and flow state of the fluid can be controlled more accurately, especially in environments where the flow rate needs to be gradually adjusted or sudden pressure fluctuations in the system are prevented, which can provide higher stability and safety. Suitable for production links that have extremely high requirements for fluid flow processes, such as pharmaceutical and dairy processing industries.

Working Principles

The working principle of the stainless steel sanitary duckbill manual butterfly valve is based on the rotation of the manually operated butterfly plate to adjust the flow of the fluid. When the handle rotates, the butterfly plate inside the valve is driven to rotate through the bearing to control the opening of the fluid channel. When closed, the valve plate completely blocks the flow channel to achieve a complete seal, which is suitable for occasions with high requirements for flow and sealing.

The options of the stainless steel sanitary duckbill manual butterfly valve include:

Sealing material: EPDM, PTFE and other sanitary sealing materials.

Drive mode: manual operation or equipped with electric/pneumatic drive.

Interface type: clamp type, threaded or flange interface.

Valve body material: 304 or 316L stainless steel.

Valve plate type: full open or half open design.

Specification Chart

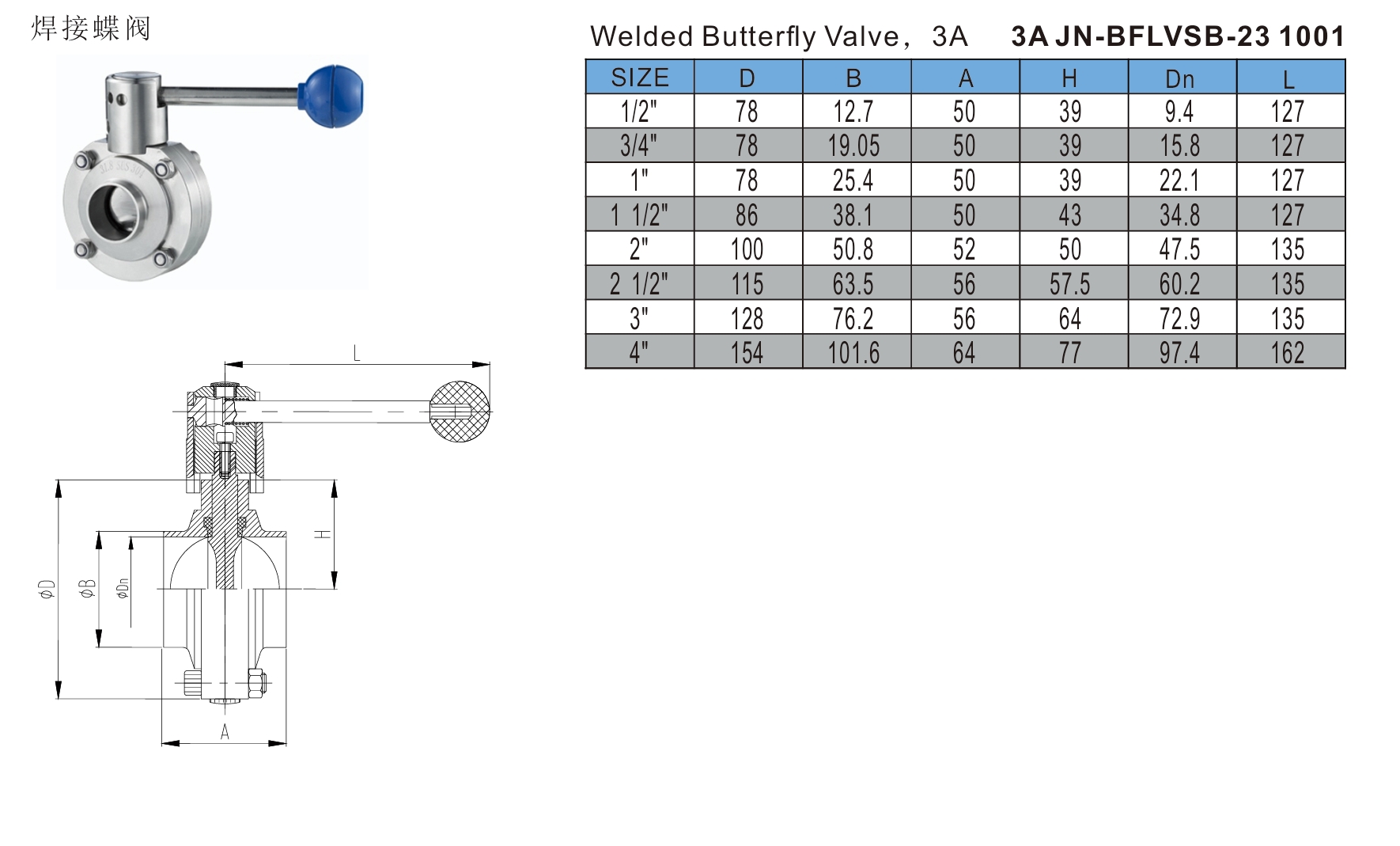

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

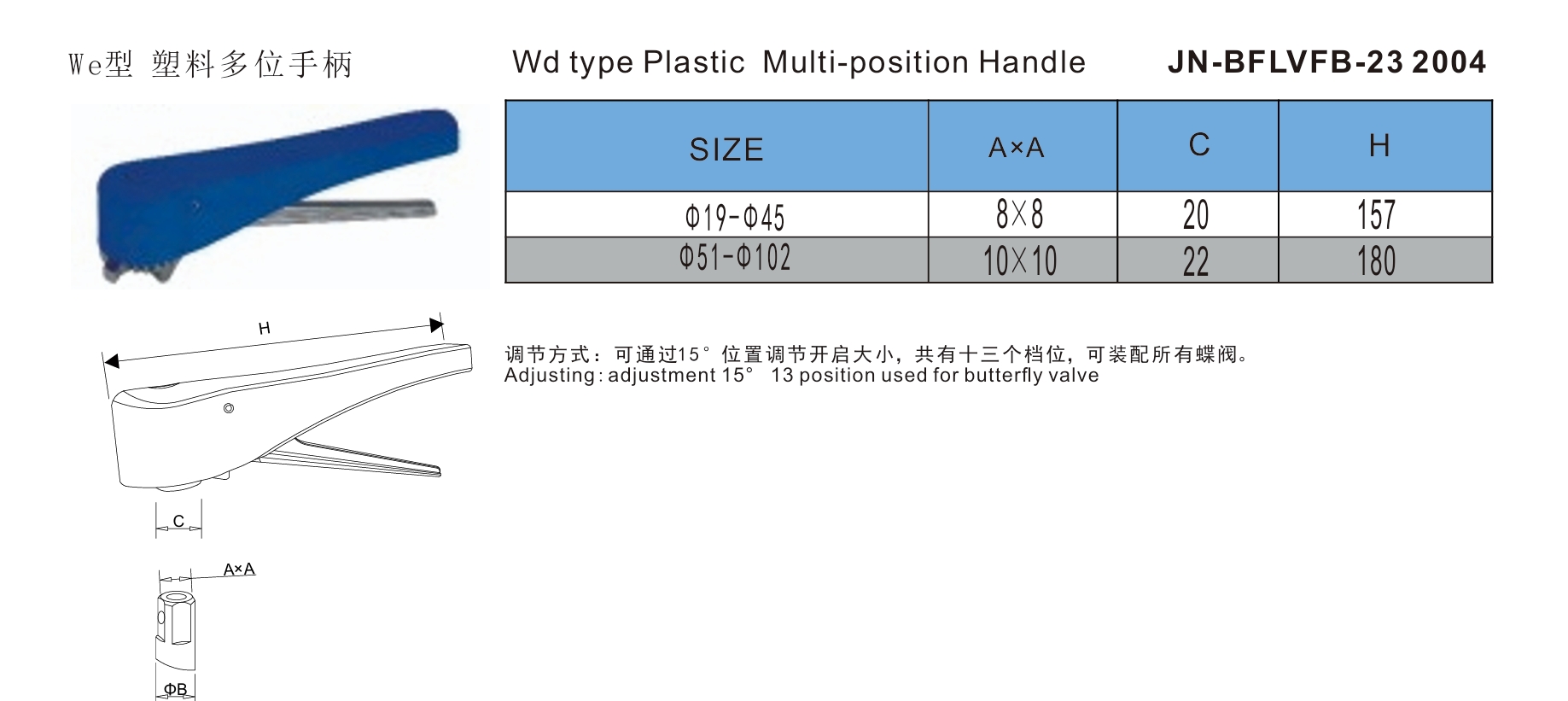

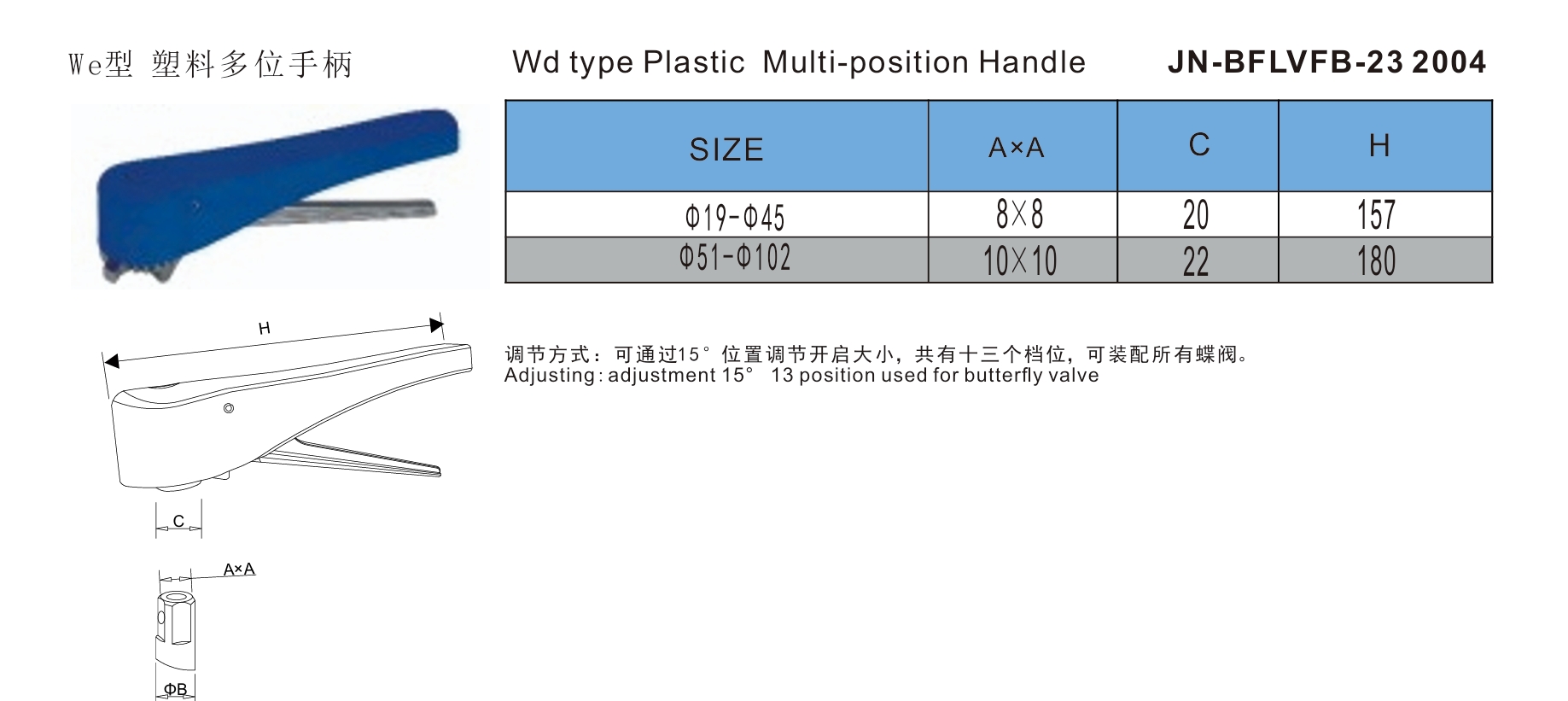

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● The stainless steel sanitary duckbill manual butterfly valve stem seal design adopts O-ring and anti-leakage design to effectively prevent liquid from leaking from the valve stem.

● The angle of the stainless steel sanitary duckbill manual butterfly valve butterfly plate is adjustable, and different flow control ranges can be set according to actual needs.

● All parts of the stainless steel sanitary duckbill manual butterfly valve that come into contact with liquid are made of corrosion-resistant stainless steel.

● The stainless steel sanitary duckbill manual butterfly valve is equipped with a humanized manual operating device, making the opening and closing of the valve very simple and fast.

● The stainless steel sanitary duckbill manual butterfly valve adopts a dead zone-free design to ensure that the fluid can flow evenly in the pipeline and reduce fluid retention.

● The stainless steel sanitary duckbill manual butterfly valve can work stably in a high temperature environment and adapt to the control needs of high-temperature fluids.

Application

The industries where stainless steel sanitary duckbill manual butterfly valves are applied are mainly the following: Food industry: used to control the flow of fluids in the production process of beverages and dairy products. Pharmaceutical industry: accurately control the flow of liquids in the manufacturing process of drugs. Chemical industry: handle chemical fluids to prevent corrosion and pollution. Beverage industry: control the flow of beverages such as juice and beer to ensure product quality. Bioengineering: used for flow regulation of fluids in bioreactors. Water treatment: used for precise flow regulation of liquids in sewage treatment systems.

Working Principles

The working principle of the stainless steel sanitary duckbill manual butterfly valve is based on the rotation of the manually operated butterfly plate to adjust the flow of the fluid. When the handle rotates, the butterfly plate inside the valve is driven to rotate through the bearing to control the opening of the fluid channel. When closed, the valve plate completely blocks the flow channel to achieve a complete seal, which is suitable for occasions with high requirements for flow and sealing.

The options of the stainless steel sanitary duckbill manual butterfly valve include:

Sealing material: EPDM, PTFE and other sanitary sealing materials.

Drive mode: manual operation or equipped with electric/pneumatic drive.

Interface type: clamp type, threaded or flange interface.

Valve body material: 304 or 316L stainless steel.

Valve plate type: full open or half open design.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Features

● The stainless steel sanitary duckbill manual butterfly valve stem seal design adopts O-ring and anti-leakage design to effectively prevent liquid from leaking from the valve stem.

● The angle of the stainless steel sanitary duckbill manual butterfly valve butterfly plate is adjustable, and different flow control ranges can be set according to actual needs.

● All parts of the stainless steel sanitary duckbill manual butterfly valve that come into contact with liquid are made of corrosion-resistant stainless steel.

● The stainless steel sanitary duckbill manual butterfly valve is equipped with a humanized manual operating device, making the opening and closing of the valve very simple and fast.

● The stainless steel sanitary duckbill manual butterfly valve adopts a dead zone-free design to ensure that the fluid can flow evenly in the pipeline and reduce fluid retention.

● The stainless steel sanitary duckbill manual butterfly valve can work stably in a high temperature environment and adapt to the control needs of high-temperature fluids.

Application

The industries where stainless steel sanitary duckbill manual butterfly valves are applied are mainly the following: Food industry: used to control the flow of fluids in the production process of beverages and dairy products. Pharmaceutical industry: accurately control the flow of liquids in the manufacturing process of drugs. Chemical industry: handle chemical fluids to prevent corrosion and pollution. Beverage industry: control the flow of beverages such as juice and beer to ensure product quality. Bioengineering: used for flow regulation of fluids in bioreactors. Water treatment: used for precise flow regulation of liquids in sewage treatment systems.