| Availability: | |

|---|---|

| Quantity: | |

JN SV 1002

JONENG

8481804090

Stainless Steel Sanitary Grade Tri-clamp Cryogenic Safety Valve

The safety valve is used to used to keep the set pressure in the system. When the system pressure is higher than set pressure, valve open to reduce the pressure, so it also named pressure relief valve or pressure release valve.

Before the valve is dispatched, we have set the pressure to given value. If needed, a pressure gauge needs to be installed before the inlet of safety valve.

Working Principles

This safety valve is a self-control valve relying on medium pressure. A specific pressure is calibrated by adjusting the compression spring of the regulating cover and the lock nut. The calibrated pressure is the maximum safe pressure value which set to avoid damage to the pipeline equipment. When the pipeline pressure exceeds the set pressure , the valve seat will automatically open, the medium is discharged and the pressure in the pipeline system is released to protect the pipeline and equipment. When the pressure of pipeline returns to the normal value, the valve seat will be forced automatically to push back, finally valve automatically closes.

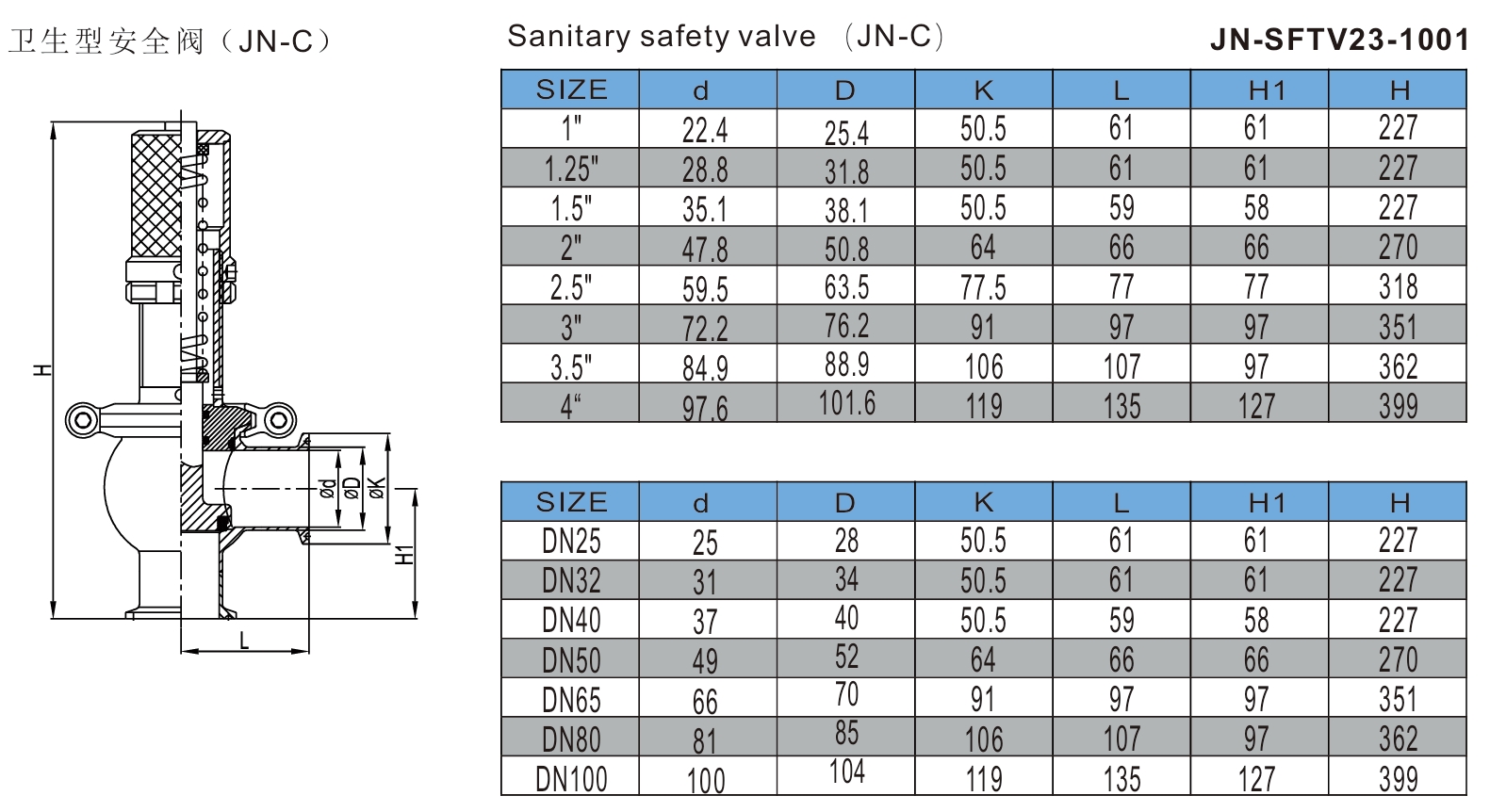

Stainless Steel Safety Valve Specification Chart

Type | Ball type, line type |

Working Pressure | 0bar-10bar |

Working Temperature | -10°C ~ +121°C |

Connection end | welded,clamped , threaded, union type |

Connection Standards | DIN, SMS, 3A, ISO |

Size | 1”-4”, DN25-DN100 |

Material | SS304, SS316L from solid bar raw material |

| With internal finishing Ra16<0.4micron | |

Surface finish | Sand blasting type, or mirror type |

Seal Material | FDA approved EPDM, VITION, NBR, SILICOME |

| Adjusting pressure | 0.5bar/unit |

| Manually adjustable to keep the system safety | |

Lock can be available for settling the relief pressure | |

Features

● Simple structure

● Compact and beautiful appearance , the valves can be installed with limit space

● Quick pressure adjustment

● Convenient maintenance

● Adjustable pressure range

● The valves can not be installed in reversal direction

● Self-draining and crevice free

Application

The sanitary safety relief (release) valves are widely used for food, beverage, dairy, pharmacy, chemical or any food processing industries

Working Principles

This safety valve is a self-control valve relying on medium pressure. A specific pressure is calibrated by adjusting the compression spring of the regulating cover and the lock nut. The calibrated pressure is the maximum safe pressure value which set to avoid damage to the pipeline equipment. When the pipeline pressure exceeds the set pressure , the valve seat will automatically open, the medium is discharged and the pressure in the pipeline system is released to protect the pipeline and equipment. When the pressure of pipeline returns to the normal value, the valve seat will be forced automatically to push back, finally valve automatically closes.

Feature and Specification

Stainless Steel Safety Valve Specification Chart

Type | Ball type, line type |

Working Pressure | 0bar-10bar |

Working Temperature | -10°C ~ +121°C |

Connection end | welded,clamped , threaded, union type |

Connection Standards | DIN, SMS, 3A, ISO |

Size | 1”-4”, DN25-DN100 |

Material | SS304, SS316L from solid bar raw material |

| With internal finishing Ra16<0.4micron | |

Surface finish | Sand blasting type, or mirror type |

Seal Material | FDA approved EPDM, VITION, NBR, SILICOME |

| Adjusting pressure | 0.5bar/unit |

| Manually adjustable to keep the system safety | |

Lock can be available for settling the relief pressure | |

Features

● Simple structure

● Compact and beautiful appearance , the valves can be installed with limit space

● Quick pressure adjustment

● Convenient maintenance

● Adjustable pressure range

● The valves can not be installed in reversal direction

● Self-draining and crevice free

Application

The sanitary safety relief (release) valves are widely used for food, beverage, dairy, pharmacy, chemical or any food processing industries