| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary bracket with base is a structural member used to support and fix pipes and equipment, and its design takes special consideration of cleaning and sanitation requirements. The stainless steel sanitary bracket with base is commonly used in pipeline systems in the food, pharmaceutical, chemical and other industries. They are installed in the support position of the pipeline, especially in the middle or corner of the horizontal or vertical pipeline. Common types of stainless steel sanitary brackets with bases include: fixed brackets, adjustable brackets, hanger brackets, angle brackets, double support brackets, and brackets with shock pads.

JONENG

8481804090

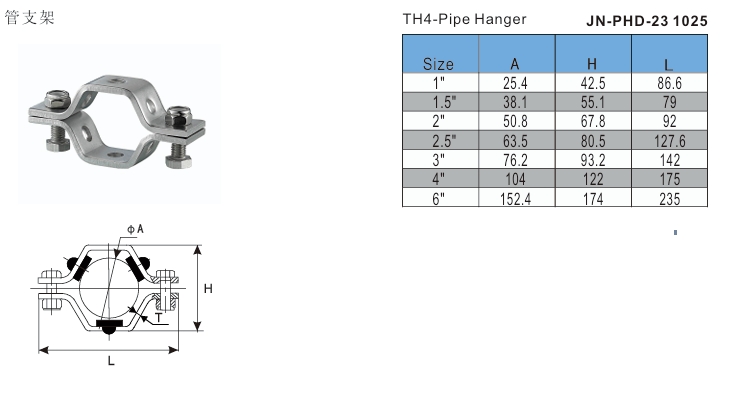

Stainless Steel Sanitary High Performance Round Bracket with Base

The design of the stainless steel sanitary bracket with base is designed to solve the stability problem of pipeline and equipment support while ensuring operation under high hygienic standards. It fixes and supports the pipeline to prevent the pipeline system from being affected by external forces during operation, causing position displacement or vibration, thereby maintaining the smooth flow of the fluid. In addition, the base design can effectively isolate the bracket from the ground, prevent dirt or moisture on the ground from contacting the pipeline, ensure that the equipment and the environment remain clean, and meet strict hygienic requirements. This bracket can improve the durability of the equipment, reduce maintenance frequency, and ensure long-term stable operation.

Working Principles

The working principle of the stainless steel sanitary bracket with base relies on the stable support and isolation of the pipeline system through the structure of the bracket and base. First, the bracket firmly fixes the pipeline in the predetermined position through a fixed or adjustable design to ensure that the pipeline does not deviate or vibrate during operation. Secondly, the design of the bracket and base enables the pipeline to evenly distribute the load when it is stressed, avoiding deformation or damage of the pipeline caused by excessive local pressure. Under the action of vibration or external force, the bracket with base can also effectively absorb and disperse vibration to ensure the long-term stability and hygiene requirements of the pipeline system.

The options of stainless steel sanitary bracket with base include:

Bracket type: fixed type, adjustable type, hanger type, etc.

Material selection: 304 stainless steel, 316 stainless steel, etc.

Bracket size: selected according to the pipe diameter and load-bearing requirements.

Base design: flat base, round base, reinforced base, etc.

Shockproof pad: whether to be equipped with shock-absorbing pads to reduce the impact of vibration.

Anti-corrosion coating: provide additional anti-corrosion protection.

Installation method: wall-mounted, ground-mounted, hanging, etc.

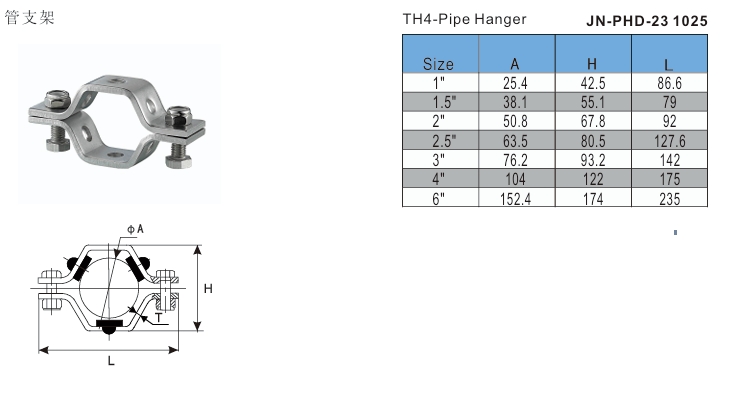

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The stainless steel sanitary bracket with base can automatically adjust the horizontality of the pipeline to ensure that the pipeline is always in the correct position after installation.

● The stainless steel sanitary bracket with base adds a layer of anti-corrosion coating on the stainless steel surface, which is particularly suitable for environments that handle corrosive substances.

● The structural design of the stainless steel sanitary bracket with base adopts the dynamic load balancing principle, which can evenly distribute pressure when subjected to external vibration or load changes, reducing the risk of uneven force on the pipeline.

● The stainless steel sanitary bracket with base is designed with a special anti-seismic energy absorption structure, which can absorb part of the energy during external vibration and reduce the impact of vibration transmission to the pipeline.

● The stainless steel sanitary bracket with base adopts a modular design. Users can choose different modules to combine according to their needs to adapt to pipelines of different sizes and configurations.

● The connection of the stainless steel sanitary bracket with base is designed with low friction material or coating to reduce wear and energy loss caused by friction.

Application

Stainless steel sanitary bracket with base is widely used in the following industries: Food industry: used for pipeline support to ensure product safety and hygiene. Pharmaceutical industry: suitable for pipeline installation and fixation in sterile environment. Chemical industry: support chemical pipelines to prevent leakage of corrosive substances. Beverage industry: high requirements for pipeline installation stability to prevent pollution. Dairy industry: pipeline cleaning is convenient to ensure product purity. Bioengineering: used for pipeline support in high-demand sanitary environments. Water treatment industry: ensure safe and stable operation of pipeline systems. Steam treatment: support high-temperature pipelines to ensure safe operation of the system.

Working Principles

The working principle of the stainless steel sanitary bracket with base relies on the stable support and isolation of the pipeline system through the structure of the bracket and base. First, the bracket firmly fixes the pipeline in the predetermined position through a fixed or adjustable design to ensure that the pipeline does not deviate or vibrate during operation. Secondly, the design of the bracket and base enables the pipeline to evenly distribute the load when it is stressed, avoiding deformation or damage of the pipeline caused by excessive local pressure. Under the action of vibration or external force, the bracket with base can also effectively absorb and disperse vibration to ensure the long-term stability and hygiene requirements of the pipeline system.

The options of stainless steel sanitary bracket with base include:

Bracket type: fixed type, adjustable type, hanger type, etc.

Material selection: 304 stainless steel, 316 stainless steel, etc.

Bracket size: selected according to the pipe diameter and load-bearing requirements.

Base design: flat base, round base, reinforced base, etc.

Shockproof pad: whether to be equipped with shock-absorbing pads to reduce the impact of vibration.

Anti-corrosion coating: provide additional anti-corrosion protection.

Installation method: wall-mounted, ground-mounted, hanging, etc.

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The stainless steel sanitary bracket with base can automatically adjust the horizontality of the pipeline to ensure that the pipeline is always in the correct position after installation.

● The stainless steel sanitary bracket with base adds a layer of anti-corrosion coating on the stainless steel surface, which is particularly suitable for environments that handle corrosive substances.

● The structural design of the stainless steel sanitary bracket with base adopts the dynamic load balancing principle, which can evenly distribute pressure when subjected to external vibration or load changes, reducing the risk of uneven force on the pipeline.

● The stainless steel sanitary bracket with base is designed with a special anti-seismic energy absorption structure, which can absorb part of the energy during external vibration and reduce the impact of vibration transmission to the pipeline.

● The stainless steel sanitary bracket with base adopts a modular design. Users can choose different modules to combine according to their needs to adapt to pipelines of different sizes and configurations.

● The connection of the stainless steel sanitary bracket with base is designed with low friction material or coating to reduce wear and energy loss caused by friction.

Application

Stainless steel sanitary bracket with base is widely used in the following industries: Food industry: used for pipeline support to ensure product safety and hygiene. Pharmaceutical industry: suitable for pipeline installation and fixation in sterile environment. Chemical industry: support chemical pipelines to prevent leakage of corrosive substances. Beverage industry: high requirements for pipeline installation stability to prevent pollution. Dairy industry: pipeline cleaning is convenient to ensure product purity. Bioengineering: used for pipeline support in high-demand sanitary environments. Water treatment industry: ensure safe and stable operation of pipeline systems. Steam treatment: support high-temperature pipelines to ensure safe operation of the system.