| Availability: | |

|---|---|

| Quantity: | |

The stainless steel double-bolt round pipe bracket is a pipe fixing designed for round pipe fixing. The stainless steel double-bolt round pipe bracket is mainly used for fixing and supporting sanitary stainless steel round pipes. It is usually installed at the wall support point when the pipe is laid along the wall, the hoisting point of the ceiling suspension section, the stable point of the equipment interface pipe section, and the pipe corner or key stress position. Common types of stainless steel double-bolt round pipe brackets include: standard double-bolt pipe bracket, widened double-bolt pipe bracket, double-bolt pipe bracket with anti-vibration pad, and one-piece base double-bolt pipe bracket.

JONENG

8481804090

Stainless Steel Sanitary High Performance Two-Bolt Round Pipe Bracket

The stainless steel double-bolt round pipe bracket is not just a simple fixing device. Its core design purpose is to provide double-point precise locking and impact-resistant buffering functions for sanitary pipe systems. It takes into account the slight vibration of clean pipes in dynamic liquid transportation, the dimensional drift caused by thermal expansion and contraction, and the axial thrust that the pipe may be subjected to when the equipment is started and stopped. The double-bolt structure ensures that the pipe can maintain a stable support state even under complex working conditions, and is convenient for regular disassembly and cleaning or position fine-tuning, taking into account durability, fatigue resistance and maintenance convenience.

Working Principles

The working principle of the stainless steel double-bolt circular pipe bracket is based on the principle of double-point clamping and locking and evenly distributed stress to fix the pipe. During installation, first select a bracket of matching size according to the pipe diameter, put the pipe into the lower half of the bracket, and then cover the outer wall of the pipe with the upper half of the bracket to form a complete wrapping structure. By gradually tightening the double bolts on both sides at the same time, the pre-tightening force of the bolts drives the inner side of the ring to evenly fit the pipe surface to achieve full circumferential clamping. The bracket base is fixed on the wall, bracket beam or ceiling hanger to form a stable three-point force system: the bracket base bears the dead weight of the pipe, the double bolts embrace the outer wall of the pipe to limit radial and axial displacement, and the thread pre-tightening force offsets the stress impact caused by slight expansion or vibration of the pipe.

Stainless steel double bolt round tube bracket options:

Material: 304, 316L

Surface treatment: mirror polishing, pickling passivation

Pad: silicone, EPDM, PTFE or no pad

Base type: flat bottom, U-shaped, guide rail sliding type

Bolt type: standard bolt, quick release bolt

Height adjustment: fixed type, adjustable type

Installation method: wall mount, floor mount, hanging mount

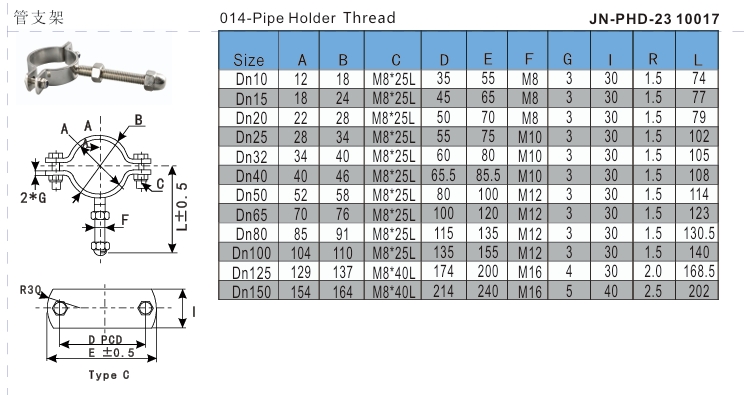

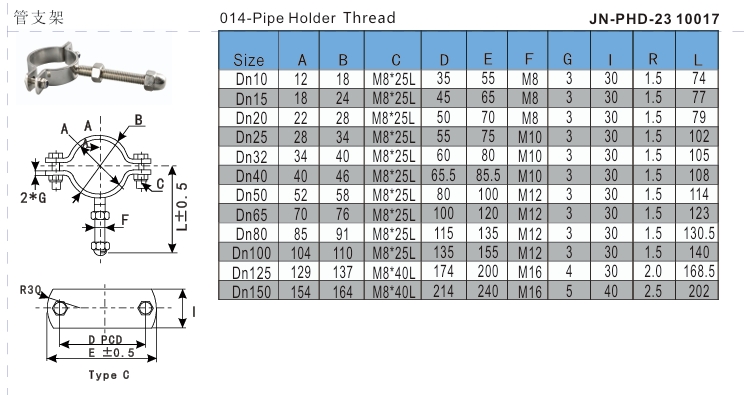

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The upper and lower semicircular clamping rings of the stainless steel double-bolt round pipe bracket adopt specific tolerance control to ensure that the two half rings form a full-circumferential isobaric fitting surface after closing, and the pipeline surface will not be sunken or stressed due to excessive or insufficient local bolt tightening force.

● The stainless steel double-bolt round pipe bracket is designed with a hidden micro-step structure on the inner side of the clamping ring. The step height matches the pipe wall thickness to form a secondary positioning effect without affecting surface cleaning.

● The double bolts of the stainless steel double-bolt round pipe bracket are not simply symmetrically distributed, but the connection angle between the bolt and the clamping ring is fine-tuned according to parameters such as pipe diameter, fluid medium density, and pipeline vibration frequency.

● The stainless steel double-bolt round pipe bracket is pre-installed with a wear-resistant PTFE anti-slip bushing inside the hole where the bolt passes through the clamping ring, and the outer layer of the bushing fits the bolt thread.

● The stainless steel double-bolt round pipe bracket adds a micro anti-slip ring groove in the thread area outside the bolt, which is used in conjunction with a special double-tooth anti-loosening nut to prevent the bolt from loosening due to equipment vibration or thermal expansion and contraction of the pipeline.

● The welding part of the stainless steel double-bolt circular tube bracket base and the connection surface of the clamping ring adopt the electrolytic flattening process to eliminate the micro-ripples caused by welding thermal deformation, ensure the full contact and seamless fit of the ring surface and the pipeline, and avoid the hidden dangers of residual liquid or bacteria breeding during the cleaning process.

Application

Stainless steel double bolt round pipe brackets are widely used in the following industries: Food processing: ensure that the pipeline transmits fluid stably to avoid vibration contamination during food processing. Beverage production: stabilize the pipeline of the beverage production line to ensure the sealing and stability of the fluid transportation process and prevent the movement of the pipeline from affecting production efficiency. Dairy processing: support the pipeline of the dairy production line to ensure that the pipeline is not affected by external forces, meet hygiene requirements, and avoid bacterial growth. Beer brewing: fix the pipeline in the beer brewing process to prevent vibration or displacement from affecting fluid flow and ensure production quality. Pharmaceutical industry: prevent any form of pollution or pipeline damage and meet pharmaceutical production standards. Biological fermentation: support and fix the pipeline system for conveying liquids in biological fermentation projects to avoid the fermentation process affected by pipeline displacement. Fine chemicals: support pipelines during chemical reactions to avoid chemical leakage or pipeline damage and ensure production safety and stability.

Working Principles

The working principle of the stainless steel double-bolt circular pipe bracket is based on the principle of double-point clamping and locking and evenly distributed stress to fix the pipe. During installation, first select a bracket of matching size according to the pipe diameter, put the pipe into the lower half of the bracket, and then cover the outer wall of the pipe with the upper half of the bracket to form a complete wrapping structure. By gradually tightening the double bolts on both sides at the same time, the pre-tightening force of the bolts drives the inner side of the ring to evenly fit the pipe surface to achieve full circumferential clamping. The bracket base is fixed on the wall, bracket beam or ceiling hanger to form a stable three-point force system: the bracket base bears the dead weight of the pipe, the double bolts embrace the outer wall of the pipe to limit radial and axial displacement, and the thread pre-tightening force offsets the stress impact caused by slight expansion or vibration of the pipe.

Stainless steel double bolt round tube bracket options:

Material: 304, 316L

Surface treatment: mirror polishing, pickling passivation

Pad: silicone, EPDM, PTFE or no pad

Base type: flat bottom, U-shaped, guide rail sliding type

Bolt type: standard bolt, quick release bolt

Height adjustment: fixed type, adjustable type

Installation method: wall mount, floor mount, hanging mount

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The upper and lower semicircular clamping rings of the stainless steel double-bolt round pipe bracket adopt specific tolerance control to ensure that the two half rings form a full-circumferential isobaric fitting surface after closing, and the pipeline surface will not be sunken or stressed due to excessive or insufficient local bolt tightening force.

● The stainless steel double-bolt round pipe bracket is designed with a hidden micro-step structure on the inner side of the clamping ring. The step height matches the pipe wall thickness to form a secondary positioning effect without affecting surface cleaning.

● The double bolts of the stainless steel double-bolt round pipe bracket are not simply symmetrically distributed, but the connection angle between the bolt and the clamping ring is fine-tuned according to parameters such as pipe diameter, fluid medium density, and pipeline vibration frequency.

● The stainless steel double-bolt round pipe bracket is pre-installed with a wear-resistant PTFE anti-slip bushing inside the hole where the bolt passes through the clamping ring, and the outer layer of the bushing fits the bolt thread.

● The stainless steel double-bolt round pipe bracket adds a micro anti-slip ring groove in the thread area outside the bolt, which is used in conjunction with a special double-tooth anti-loosening nut to prevent the bolt from loosening due to equipment vibration or thermal expansion and contraction of the pipeline.

● The welding part of the stainless steel double-bolt circular tube bracket base and the connection surface of the clamping ring adopt the electrolytic flattening process to eliminate the micro-ripples caused by welding thermal deformation, ensure the full contact and seamless fit of the ring surface and the pipeline, and avoid the hidden dangers of residual liquid or bacteria breeding during the cleaning process.

Application

Stainless steel double bolt round pipe brackets are widely used in the following industries: Food processing: ensure that the pipeline transmits fluid stably to avoid vibration contamination during food processing. Beverage production: stabilize the pipeline of the beverage production line to ensure the sealing and stability of the fluid transportation process and prevent the movement of the pipeline from affecting production efficiency. Dairy processing: support the pipeline of the dairy production line to ensure that the pipeline is not affected by external forces, meet hygiene requirements, and avoid bacterial growth. Beer brewing: fix the pipeline in the beer brewing process to prevent vibration or displacement from affecting fluid flow and ensure production quality. Pharmaceutical industry: prevent any form of pollution or pipeline damage and meet pharmaceutical production standards. Biological fermentation: support and fix the pipeline system for conveying liquids in biological fermentation projects to avoid the fermentation process affected by pipeline displacement. Fine chemicals: support pipelines during chemical reactions to avoid chemical leakage or pipeline damage and ensure production safety and stability.