| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless Steel Sanitary Manual Fluoropolymer-lined Diaphragm Valve

The Stainless Steel Sanitary Manual Fluoropolymer-lined Diaphragm Valve is a hygienic hand-operated valve designed for corrosive or high-purity media. Its fluoropolymer lining enhances chemical resistance, while the diaphragm provides a clean, leak-free seal suitable for sanitary fluid control.

Working Principles

The Stainless Steel Sanitary Manual Fluoropolymer-lined Diaphragm Valve operates by using a handwheel to manually move a stem connected to a flexible diaphragm. When the handwheel is turned, the stem pushes the diaphragm downward to seal against the valve seat, stopping flow, or lifts it to allow media to pass. The fluoropolymer lining provides a chemically resistant barrier between the process fluid and the metal body, ensuring safe handling of corrosive or high-purity media. The diaphragm isolates the fluid from mechanical components, preventing contamination and ensuring sanitary performance. This design delivers reliable shutoff, smooth flow control, and easy maintenance in hygienic applications

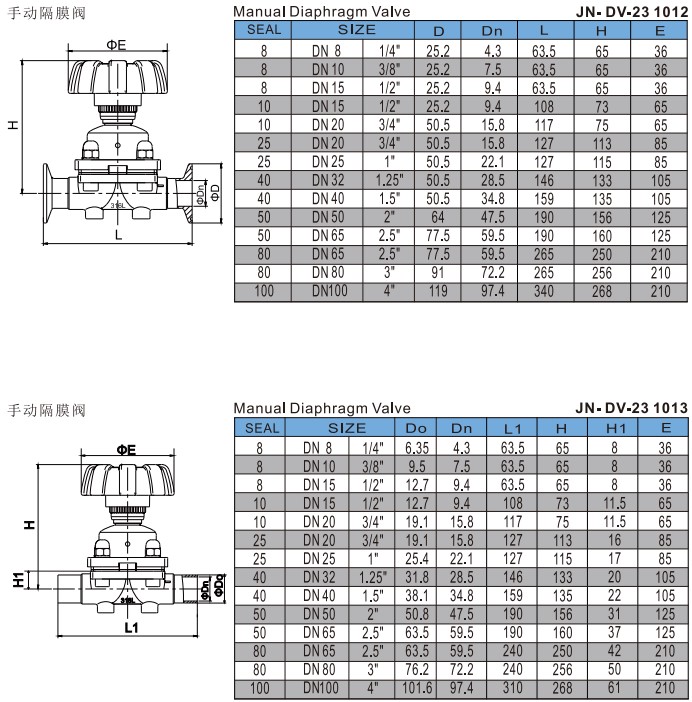

Stainless Steel Diaphragm Valve Specification Chart

Body Material | Stainless Steel 304 / 316L |

Lining Material | PTFE / PFA / FEP Fluoropolymer |

Diaphragm Material | 1" to 6" |

Operation Mode | Manual Handwheel |

Connection Style | Clamp, Welded, or Threaded Sanitary Connections |

Nominal Sizes | DN10 – DN100 (or customer-specified) |

Design Standard | Sanitary / Hygienic Valve Standards |

Working Pressure | ≤ 10 bar (varies by size and lining) |

Working Temperature | -20°C to 150°C (depending on fluoropolymer lining) |

Surface Finish | Ra ≤ 0.8 μm (internal), sanitary polished |

Features

The fluoropolymer lining provides exceptional chemical resistance, allowing the valve to handle corrosive or high-purity media without degrading or contaminating the process.

The sanitary diaphragm design isolates the fluid from moving parts, ensuring a clean flow path and preventing microbial buildup in hygienic applications.

Manual handwheel operation offers simple, precise control for throttling or shutoff, making it suitable for systems requiring reliable manual adjustment.

Smooth, crevice-free stainless steel construction enhances cleanliness and supports easy CIP/SIP procedures in sanitary processing environments.

Multiple connection options, including clamp, welded, and threaded ends, allow flexible installation and compatibility with various hygienic pipeline systems.

Application

The Stainless Steel Sanitary Manual Fluoropolymer-lined Diaphragm Valve is widely used in industries requiring corrosion-resistant and hygienic flow control. Typical applications include chemical processing for acids and solvents, pharmaceutical production for sterile solutions, biotechnology for culture media, and food processing for high-purity or acidic liquids.

Working Principles

The Stainless Steel Sanitary Manual Fluoropolymer-lined Diaphragm Valve operates by using a handwheel to manually move a stem connected to a flexible diaphragm. When the handwheel is turned, the stem pushes the diaphragm downward to seal against the valve seat, stopping flow, or lifts it to allow media to pass. The fluoropolymer lining provides a chemically resistant barrier between the process fluid and the metal body, ensuring safe handling of corrosive or high-purity media. The diaphragm isolates the fluid from mechanical components, preventing contamination and ensuring sanitary performance. This design delivers reliable shutoff, smooth flow control, and easy maintenance in hygienic applications

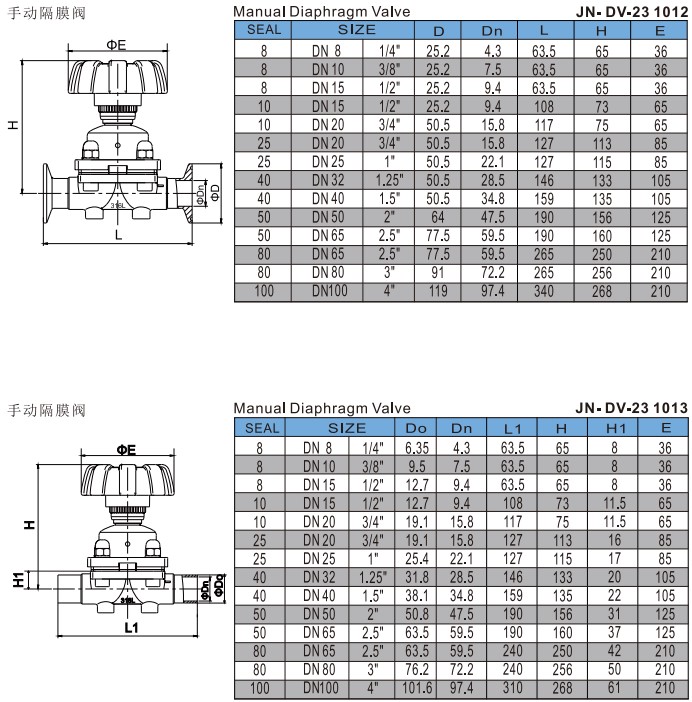

Stainless Steel Diaphragm Valve Specification Chart

Body Material | Stainless Steel 304 / 316L |

Lining Material | PTFE / PFA / FEP Fluoropolymer |

Diaphragm Material | 1" to 6" |

Operation Mode | Manual Handwheel |

Connection Style | Clamp, Welded, or Threaded Sanitary Connections |

Nominal Sizes | DN10 – DN100 (or customer-specified) |

Design Standard | Sanitary / Hygienic Valve Standards |

Working Pressure | ≤ 10 bar (varies by size and lining) |

Working Temperature | -20°C to 150°C (depending on fluoropolymer lining) |

Surface Finish | Ra ≤ 0.8 μm (internal), sanitary polished |

Features

The fluoropolymer lining provides exceptional chemical resistance, allowing the valve to handle corrosive or high-purity media without degrading or contaminating the process.

The sanitary diaphragm design isolates the fluid from moving parts, ensuring a clean flow path and preventing microbial buildup in hygienic applications.

Manual handwheel operation offers simple, precise control for throttling or shutoff, making it suitable for systems requiring reliable manual adjustment.

Smooth, crevice-free stainless steel construction enhances cleanliness and supports easy CIP/SIP procedures in sanitary processing environments.

Multiple connection options, including clamp, welded, and threaded ends, allow flexible installation and compatibility with various hygienic pipeline systems.

Application

The Stainless Steel Sanitary Manual Fluoropolymer-lined Diaphragm Valve is widely used in industries requiring corrosion-resistant and hygienic flow control. Typical applications include chemical processing for acids and solvents, pharmaceutical production for sterile solutions, biotechnology for culture media, and food processing for high-purity or acidic liquids.