| Availability: | |

|---|---|

| Quantity: | |

Stainless steel sanitary quick-release connectors are usually made of stainless steel materials (such as 304, 316L). Their design features are that they are very convenient and fast to connect and disassemble, without the need for additional tools or welding. Stainless steel sanitary quick-release connectors are used for quick connection and disassembly of pipeline systems to ensure hygienic, safe and convenient operation.

Stainless steel sanitary quick-release connectors are widely used in pipeline systems in the food, beverage, pharmaceutical and other industries. They are usually used to connect the inlets and outlets of pipelines, valves, pumps, storage tanks and other equipment. There are mainly the following types of stainless steel sanitary quick-release connectors: clamp connectors, threaded connectors, welded connectors, and quick-release connectors.

JONENG

8421219990

Stainless Steel Sanitary Mirror Polished Quick Release Connector

The main purpose of the design of stainless steel sanitary quick-release connectors is to provide a convenient, fast and hygienic way to connect pipelines. Through quick installation and disassembly, the time for maintenance and cleaning is reduced, which is particularly suitable for the food, beverage, pharmaceutical and other industries. Its no dead angle and smooth surface ensure the hygiene of the system and avoid contamination and bacterial growth. Made of stainless steel, it has good corrosion resistance and high temperature resistance, ensuring the long-term stable operation of the pipeline system and meeting high standards of hygiene and safety requirements.

Working Principles

The working principle of the stainless steel sanitary quick-release connector is to achieve quick connection and sealing of the pipe through the clamp and the sealing gasket. After the two ends of the connector are butt-jointed, the sealing gasket is compressed to ensure that there is no leakage at the pipe connection. The clamp or clamping ring firmly fixes the connector to prevent loosening due to pipe vibration or pressure changes. When disassembling, it can be quickly separated by loosening the clamp or rotating it, without tools, which is convenient for cleaning and maintenance. This design ensures the stability and hygiene of the connection and is suitable for industries with high hygiene requirements. The use of stainless steel sanitary quick-release connectors can achieve fast and convenient pipe connection and disassembly, ensure the sealing and hygiene of the system, and reduce maintenance time.

The options of stainless steel sanitary quick-release connectors include: sealing materials such as EPDM, Viton, PTFE, etc.; surface treatments such as mirror polishing and passivation; port types such as flat end and flange end.

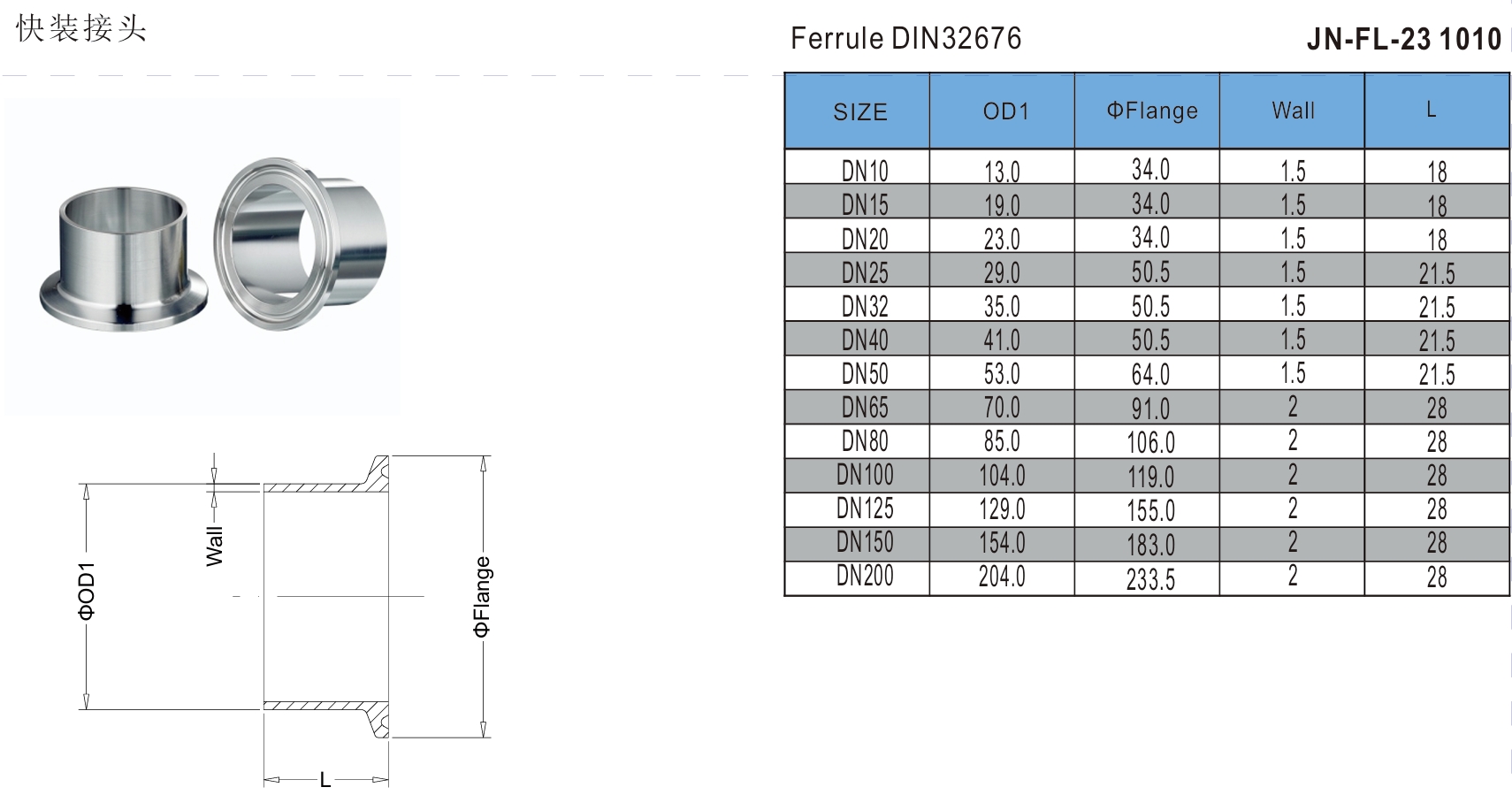

Specification Chart

Material | ASI304, 316L |

Size | ½ “ to 12” |

Gaskets or seals | Silicone, EPDM, Viton,NBR.. |

Pressure | 6 to 20 bars |

Temperature | 20C to 150C |

Standard | SMS, DIN, 3A,RJT,BSM,IDF.. |

Features

● The stainless steel sanitary quick-release connector adopts a clamp or quick-release design. No additional tools are required for the connection and removal process, which greatly improves the convenience of operation.

● The clamp connection of the stainless steel sanitary quick-release connector does not require welding, and the pipe is firmly connected with a clamp and a sealing gasket.

● The stainless steel sanitary quick-release connector can withstand higher flow and pressure, and is suitable for large flow systems.

● The stainless steel sanitary quick-release connector automatically docks when connected and achieves self-sealing without additional operation.

● The stainless steel sanitary quick-release connector has strong shock resistance and impact resistance, and can withstand pipeline vibration and impact.

● The internal structure of the stainless steel sanitary quick-release connector is smooth, without dead corners or difficult-to-clean parts, avoiding material accumulation.

Application

Stainless steel sanitary quick-release connectors are widely used in the following industries: Food and beverage industry: ensure the hygiene of the pipeline system and prevent pollution. Pharmaceutical industry: ensure the safety and purity of the drug production process. Cosmetics industry: ensure the pollution-free raw materials and products. Dairy industry: ensure hygiene and efficient flow of fluids. Biopharmaceutical industry: avoid bacteria and pollution, and meet GMP standards. Chemical industry: used for the transportation and production of chemical raw materials, corrosion-resistant and high-temperature resistant.

Working Principles

The working principle of the stainless steel sanitary quick-release connector is to achieve quick connection and sealing of the pipe through the clamp and the sealing gasket. After the two ends of the connector are butt-jointed, the sealing gasket is compressed to ensure that there is no leakage at the pipe connection. The clamp or clamping ring firmly fixes the connector to prevent loosening due to pipe vibration or pressure changes. When disassembling, it can be quickly separated by loosening the clamp or rotating it, without tools, which is convenient for cleaning and maintenance. This design ensures the stability and hygiene of the connection and is suitable for industries with high hygiene requirements. The use of stainless steel sanitary quick-release connectors can achieve fast and convenient pipe connection and disassembly, ensure the sealing and hygiene of the system, and reduce maintenance time.

Specification Chart

Material | ASI304, 316L |

Size | ½ “ to 12” |

Gaskets or seals | Silicone, EPDM, Viton,NBR.. |

Pressure | 6 to 20 bars |

Temperature | 20C to 150C |

Standard | SMS, DIN, 3A,RJT,BSM,IDF.. |

Features

● The stainless steel sanitary quick-release connector adopts a clamp or quick-release design. No additional tools are required for the connection and removal process, which greatly improves the convenience of operation.

● The clamp connection of the stainless steel sanitary quick-release connector does not require welding, and the pipe is firmly connected with a clamp and a sealing gasket.

● The stainless steel sanitary quick-release connector can withstand higher flow and pressure, and is suitable for large flow systems.

● The stainless steel sanitary quick-release connector automatically docks when connected and achieves self-sealing without additional operation.

● The stainless steel sanitary quick-release connector has strong shock resistance and impact resistance, and can withstand pipeline vibration and impact.

● The internal structure of the stainless steel sanitary quick-release connector is smooth, without dead corners or difficult-to-clean parts, avoiding material accumulation.

Application

Stainless steel sanitary quick-release connectors are widely used in the following industries: Food and beverage industry: ensure the hygiene of the pipeline system and prevent pollution. Pharmaceutical industry: ensure the safety and purity of the drug production process. Cosmetics industry: ensure the pollution-free raw materials and products. Dairy industry: ensure hygiene and efficient flow of fluids. Biopharmaceutical industry: avoid bacteria and pollution, and meet GMP standards. Chemical industry: used for the transportation and production of chemical raw materials, corrosion-resistant and high-temperature resistant.