| Availability: | |

|---|---|

| Quantity: | |

AS1528.3- JN-FT-20 5005

JONENG

7307290000

Stainless Steel Sanitary Mirror Polished Welding 90 Degree Elbow

Stainless steel sanitary welded elbows are not only simple pipe corner connectors, but also core components for optimizing fluid flow, reducing turbulent resistance, and reducing pollutant deposition. Its precise curvature radius design helps to maintain the laminar state of the fluid, avoid bubbles or shear forces caused by turbulence, and thus protect the physical and chemical stability of sensitive media. Especially in the fields of pharmaceuticals, biological fermentation, and high-purity food production, it eliminates the dead corners of traditional connectors and reduces the risk of microbial growth through seamless welding. At the same time, the high-precision polishing of its inner wall ensures that the fluid contact surface is extremely smooth, which not only reduces material residue, but also facilitates CIP/SIP online cleaning, improves the hygiene level of the pipeline system, and extends the service life of the equipment.

Working Principles

The working principle of the stainless steel sanitary welded elbow is based on the fluid dynamics optimization of the pipeline system. It changes the flow direction of the fluid through a specific bending angle, while maintaining a stable flow rate and reducing pressure loss and turbulence. Its working steps are as follows: First, the fluid enters the inlet area of the elbow from the straight pipe section. Due to the design of the pipe diameter and bending radius, the flow rate is evenly distributed inside the elbow to avoid eddy currents. Then, when the fluid passes through the curved section, the high-precision polishing of the inner wall reduces the friction resistance between the fluid and the pipe wall, ensuring smooth passage of the medium while reducing the risk of retention of particles or microorganisms. Next, the streamlined design of the elbow allows the fluid to maintain a laminar state when turning, avoiding shear force or bubble formation caused by turbulence, and protecting the fluid characteristics. Finally, the fluid smoothly enters the downstream pipeline from the elbow outlet and maintains a stable flow.

The options for stainless steel sanitary welded elbows include:

Angle selection: conventional 90°, 45°, 180°, or customized special angles.

Radius type: long radius and short radius are optional to adapt to different fluid characteristics.

Wall thickness specifications: a variety of wall thicknesses are available to adapt to different pressure and durability requirements.

Surface treatment: internal and external electrolytic polishing, mechanical polishing or sandblasting.

Material selection: 304, 316L stainless steel, suitable for different media and working conditions.

Interface mode: optional butt welding, flare welding, flanged or customized interface.

Special coating: optional PTFE or antibacterial coating to improve corrosion resistance or hygienic performance.

Testing and certification: optional 3A, FDA, GMP and other certifications to meet industry standards.

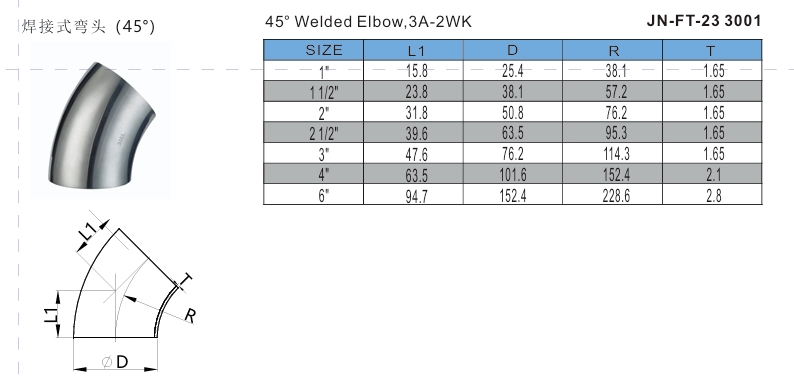

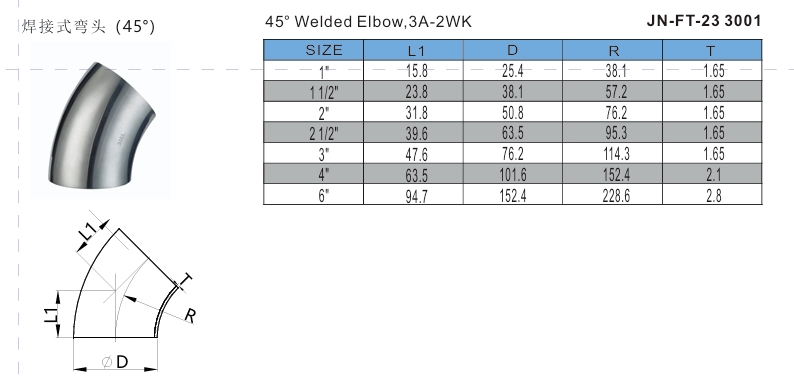

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The inner wall of the stainless steel sanitary welded elbow adopts a micro-arc transition structure, without obvious sharp angles or dead angles, which reduces fluid retention, reduces the risk of microbial breeding, and improves the hygiene level.

● The stainless steel sanitary welded elbow optimizes the bending radius and angle through CFD (computational fluid dynamics), reduces turbulence and pressure loss, and makes the fluid flow smoother.

● After welding, the internal weld of the stainless steel sanitary welded elbow adopts automatic mechanical polishing or electrolytic polishing to ensure that the weld area is as smooth as the inner wall of the pipe to avoid particle deposition.

● The stainless steel sanitary welded elbow adopts high-purity argon protection oxygen-free welding process to effectively prevent weld oxidation, improve welding strength and corrosion resistance, and avoid contamination of the medium due to the shedding of the oxide layer.

● The stainless steel sanitary welded elbow adopts laser weld tracking technology to accurately control the uniformity of the weld, ensure stable welding quality, avoid welding deformation, and improve welding consistency.

● For high flow rate or high-frequency pressure fluctuation environment, the stainless steel sanitary welded elbow adds reinforcement ribs or thick wall design at specific angles to prevent structural fatigue and weld cracks caused by resonance.

Application

Stainless steel sanitary welding elbows are widely used in the following industries: Food industry: used in beverage and dairy product pipeline systems to ensure hygiene. Pharmaceutical industry: meet the aseptic transmission requirements of drug production. Bioengineering: suitable for high-cleanliness fluid transportation. Cosmetic industry: ensure the hygiene and safety of raw materials and products. Chemical industry: corrosion-resistant, suitable for high-purity chemical transportation. Semiconductor industry: used for ultrapure water and high-purity gas pipelines. Brewing industry: used for fermentation liquid transportation to ensure purity.

Working Principles

The working principle of the stainless steel sanitary welded elbow is based on the fluid dynamics optimization of the pipeline system. It changes the flow direction of the fluid through a specific bending angle, while maintaining a stable flow rate and reducing pressure loss and turbulence. Its working steps are as follows: First, the fluid enters the inlet area of the elbow from the straight pipe section. Due to the design of the pipe diameter and bending radius, the flow rate is evenly distributed inside the elbow to avoid eddy currents. Then, when the fluid passes through the curved section, the high-precision polishing of the inner wall reduces the friction resistance between the fluid and the pipe wall, ensuring smooth passage of the medium while reducing the risk of retention of particles or microorganisms. Next, the streamlined design of the elbow allows the fluid to maintain a laminar state when turning, avoiding shear force or bubble formation caused by turbulence, and protecting the fluid characteristics. Finally, the fluid smoothly enters the downstream pipeline from the elbow outlet and maintains a stable flow.

The options for stainless steel sanitary welded elbows include:

Angle selection: conventional 90°, 45°, 180°, or customized special angles.

Radius type: long radius and short radius are optional to adapt to different fluid characteristics.

Wall thickness specifications: a variety of wall thicknesses are available to adapt to different pressure and durability requirements.

Surface treatment: internal and external electrolytic polishing, mechanical polishing or sandblasting.

Material selection: 304, 316L stainless steel, suitable for different media and working conditions.

Interface mode: optional butt welding, flare welding, flanged or customized interface.

Special coating: optional PTFE or antibacterial coating to improve corrosion resistance or hygienic performance.

Testing and certification: optional 3A, FDA, GMP and other certifications to meet industry standards.

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The inner wall of the stainless steel sanitary welded elbow adopts a micro-arc transition structure, without obvious sharp angles or dead angles, which reduces fluid retention, reduces the risk of microbial breeding, and improves the hygiene level.

● The stainless steel sanitary welded elbow optimizes the bending radius and angle through CFD (computational fluid dynamics), reduces turbulence and pressure loss, and makes the fluid flow smoother.

● After welding, the internal weld of the stainless steel sanitary welded elbow adopts automatic mechanical polishing or electrolytic polishing to ensure that the weld area is as smooth as the inner wall of the pipe to avoid particle deposition.

● The stainless steel sanitary welded elbow adopts high-purity argon protection oxygen-free welding process to effectively prevent weld oxidation, improve welding strength and corrosion resistance, and avoid contamination of the medium due to the shedding of the oxide layer.

● The stainless steel sanitary welded elbow adopts laser weld tracking technology to accurately control the uniformity of the weld, ensure stable welding quality, avoid welding deformation, and improve welding consistency.

● For high flow rate or high-frequency pressure fluctuation environment, the stainless steel sanitary welded elbow adds reinforcement ribs or thick wall design at specific angles to prevent structural fatigue and weld cracks caused by resonance.

Application

Stainless steel sanitary welding elbows are widely used in the following industries: Food industry: used in beverage and dairy product pipeline systems to ensure hygiene. Pharmaceutical industry: meet the aseptic transmission requirements of drug production. Bioengineering: suitable for high-cleanliness fluid transportation. Cosmetic industry: ensure the hygiene and safety of raw materials and products. Chemical industry: corrosion-resistant, suitable for high-purity chemical transportation. Semiconductor industry: used for ultrapure water and high-purity gas pipelines. Brewing industry: used for fermentation liquid transportation to ensure purity.