| Availability: | |

|---|---|

| Quantity: | |

JONENG

8421219990

Stainless Steel Sanitary Ordinary Manual Tank Bottom Valve

The core purpose of the design of the stainless steel sanitary ordinary manual tank bottom valve is to provide a reliable and efficient solution when precise control of fluid discharge is required. It accurately adjusts the discharge of liquid from the bottom of the tank through manual operation to prevent any accidental leakage or contamination. In industries with strict hygiene requirements such as food and pharmaceuticals, the tank bottom valve ensures the integrity and safety of the liquid through precise structure and seamless sealing design. In addition, its special design can withstand high pressure, ensure long-term stable operation, and maintain efficient and pollution-free fluid management even in harsh environments.

Working Principles

The working principle of the stainless steel sanitary ordinary manual tank bottom valve is to control the opening and closing of the valve through manual operation to regulate the flow of liquid. First, by rotating the handle or handwheel, the valve core or valve plate inside the valve body moves to open or close the fluid channel. When opened, the sealing surface inside the valve separates from the valve seat, and the fluid can be discharged from the bottom of the tank; when closed, the valve plate or valve core is in close contact with the valve seat to ensure that the fluid stops flowing completely and avoids leakage.

Common options for stainless steel sanitary ordinary manual tank bottom valves include:

Valve body material: different types of stainless steel can be selected, such as 304, 316L, etc.

Sealing material: different sealing ring materials can be selected, such as EPDM, PTFE, etc.

Connection method: welding, threaded or flange connection can be selected.

Operation method: manual rotation of the handle or handwheel operation.

Valve size: valves of different specifications can be selected according to the pipeline size.

Valve type: different types such as ball valve, butterfly valve or gate valve.

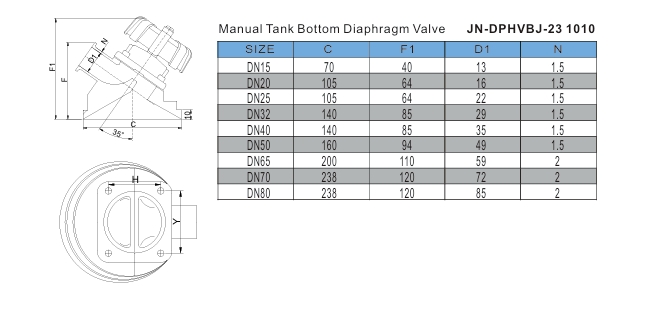

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● Stainless steel sanitary general manual tank bottom valves often have a self-cleaning design. The internal structure of the valve reduces material deposition and avoids clogging through the flushing effect of the fluid.

● Stainless steel sanitary general manual tank bottom valves adopt a multi-seal design, usually including O-rings and annular sealing structures, which can provide a stronger sealing effect.

● Stainless steel sanitary general manual tank bottom valves are designed with flow regulation function, allowing the liquid flow rate to be adjusted as needed.

● Stainless steel sanitary general manual tank bottom valves usually adopt a streamlined design to reduce the resistance of fluid flow. The flow channel inside the valve is precisely calculated to reduce the turbulence of the fluid and maintain the stability of the flow rate.

● Stainless steel sanitary general manual tank bottom valves are equipped with a special fast-response switching mechanism, allowing operators to quickly control the opening and closing of the valve. This design optimizes the operating time and is particularly suitable for production lines with frequent switching.

● Stainless steel sanitary general manual tank bottom valves use anti-corrosion coatings, usually based on polytetrafluoroethylene (PTFE) or other highly corrosion-resistant materials.

Application

Stainless steel sanitary ordinary manual tank bottom valves are widely used in the following industries: Food industry: used for the control and discharge of liquid food to ensure product safety and hygiene. Pharmaceutical industry: used for precise control of fluids in the production process of drugs, in compliance with strict hygiene standards. Beverage industry: control the production process of beverages to ensure the accuracy of liquid flow. Cosmetic industry: used for the discharge and regulation of cosmetic liquids to ensure the quality of finished products. Chemical industry: control the discharge of chemical liquids, especially in highly corrosive environments. Dairy industry: used for fluid control in dairy production to ensure the sterility of the production process.

Working Principles

The working principle of the stainless steel sanitary ordinary manual tank bottom valve is to control the opening and closing of the valve through manual operation to regulate the flow of liquid. First, by rotating the handle or handwheel, the valve core or valve plate inside the valve body moves to open or close the fluid channel. When opened, the sealing surface inside the valve separates from the valve seat, and the fluid can be discharged from the bottom of the tank; when closed, the valve plate or valve core is in close contact with the valve seat to ensure that the fluid stops flowing completely and avoids leakage.

Common options for stainless steel sanitary ordinary manual tank bottom valves include:

Valve body material: different types of stainless steel can be selected, such as 304, 316L, etc.

Sealing material: different sealing ring materials can be selected, such as EPDM, PTFE, etc.

Connection method: welding, threaded or flange connection can be selected.

Operation method: manual rotation of the handle or handwheel operation.

Valve size: valves of different specifications can be selected according to the pipeline size.

Valve type: different types such as ball valve, butterfly valve or gate valve.

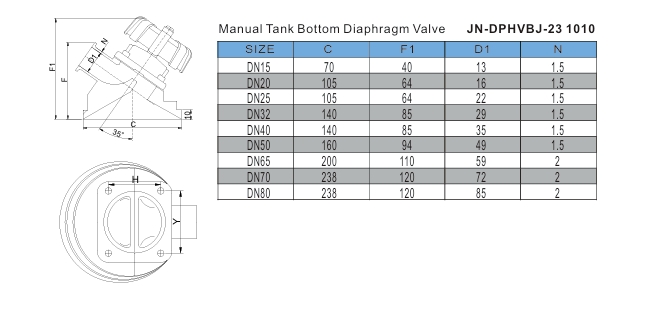

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● Stainless steel sanitary general manual tank bottom valves often have a self-cleaning design. The internal structure of the valve reduces material deposition and avoids clogging through the flushing effect of the fluid.

● Stainless steel sanitary general manual tank bottom valves adopt a multi-seal design, usually including O-rings and annular sealing structures, which can provide a stronger sealing effect.

● Stainless steel sanitary general manual tank bottom valves are designed with flow regulation function, allowing the liquid flow rate to be adjusted as needed.

● Stainless steel sanitary general manual tank bottom valves usually adopt a streamlined design to reduce the resistance of fluid flow. The flow channel inside the valve is precisely calculated to reduce the turbulence of the fluid and maintain the stability of the flow rate.

● Stainless steel sanitary general manual tank bottom valves are equipped with a special fast-response switching mechanism, allowing operators to quickly control the opening and closing of the valve. This design optimizes the operating time and is particularly suitable for production lines with frequent switching.

● Stainless steel sanitary general manual tank bottom valves use anti-corrosion coatings, usually based on polytetrafluoroethylene (PTFE) or other highly corrosion-resistant materials.

Application

Stainless steel sanitary ordinary manual tank bottom valves are widely used in the following industries: Food industry: used for the control and discharge of liquid food to ensure product safety and hygiene. Pharmaceutical industry: used for precise control of fluids in the production process of drugs, in compliance with strict hygiene standards. Beverage industry: control the production process of beverages to ensure the accuracy of liquid flow. Cosmetic industry: used for the discharge and regulation of cosmetic liquids to ensure the quality of finished products. Chemical industry: control the discharge of chemical liquids, especially in highly corrosive environments. Dairy industry: used for fluid control in dairy production to ensure the sterility of the production process.