| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless Steel Sanitary Pneumatic Intelligent Positioning Angle Seat Valve

Stainless Steel Sanitary Pneumatic Intelligent Positioning Angle Seat Valve is an automated valve designed for precise fluid control. Its intelligent positioning system allows accurate adjustment of flow, while the angle seat design ensures smooth, hygienic operation in sanitary processing applications

Working Principles

The working principle of a Stainless Steel Sanitary Pneumatic Intelligent Positioning Angle Seat Valve involves automated control of fluid flow using a pneumatic actuator combined with an intelligent positioning system. When a control signal is sent, compressed air moves the actuator piston, lifting the valve plug from the angled seat to allow fluid to flow. The intelligent positioning module continuously monitors and adjusts the valve position to maintain precise flow rates. Closing the valve reverses the actuator motion, pressing the plug firmly against the seat for a tight seal. The angled seat design ensures smooth flow, minimal pressure loss, and hygienic operation, making it suitable for automated sanitary processes requiring accurate fluid control

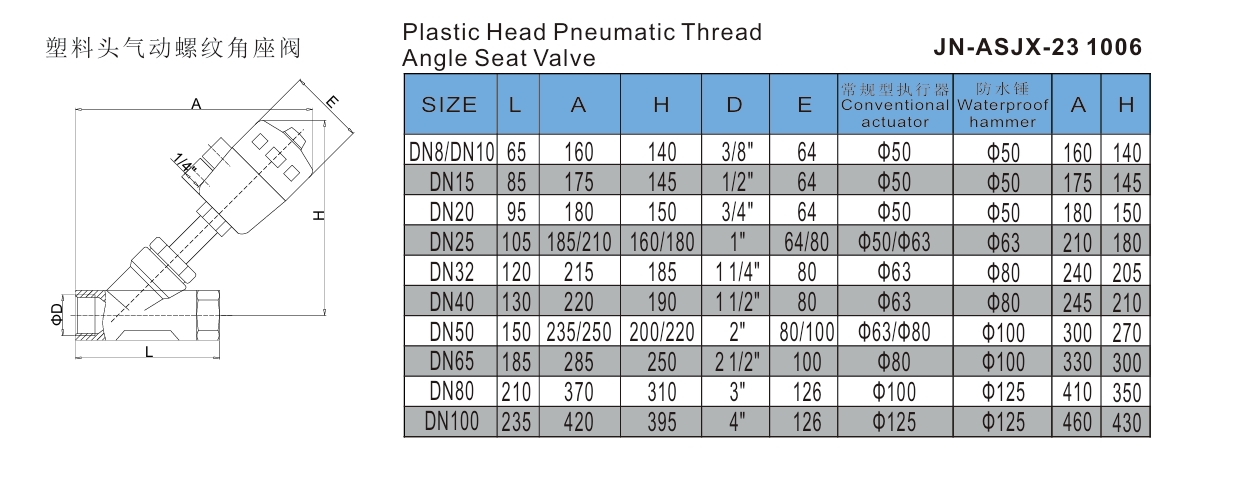

Specification Chart

Max Working Pressure | 1.6MPa |

Medium Temperature | -10℃~+180℃ |

Ambient Temperature | -10℃~+55℃ |

Body Materials | CF8M(SS316),CF8(SS304) |

Sealing Material | PTFE |

Operation | Normally Closed, Normally Open, Double-acting or Manually |

Connection End | Female, Weld,Clamp, Flange or on request |

Size Range | DN10-DN100 |

Surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Standards | DIN, SMS, ISO / IDF, BS / RJT, ASME / BPE. |

Control type | Single acting, double acting |

Features

Constructed from high-quality stainless steel, ensuring corrosion resistance, durability, and suitability for hygienic processing environments.

Pneumatic actuator with intelligent positioning provides precise, automated control of fluid flow for consistent process performance.

Angle seat design ensures smooth flow, reduces pressure loss, and supports efficient discharge in sanitary piping systems.

Hygienic polished surfaces and tight sealing prevent leakage, enabling clean-in-place (CIP) and sterilize-in-place (SIP) operations.

Compatible with control systems, offering real-time position feedback for accurate monitoring and integration into automated production lines

Application

Stainless Steel Sanitary Pneumatic Intelligent Positioning Angle Seat Valves are widely used in pharmaceutical and biotechnology industries for precise, automated control of sterile liquids in production lines. They are also applied in food and beverage manufacturing for controlling flow during mixing, filling, or heating processes. The combination of pneumatic actuation and intelligent positioning ensures accurate flow regulation, hygienic operation, and seamless integration into automated systems, making them suitable for industries requiring high precision, sanitary standards, and reliable process control

Working Principles

The working principle of a Stainless Steel Sanitary Pneumatic Intelligent Positioning Angle Seat Valve involves automated control of fluid flow using a pneumatic actuator combined with an intelligent positioning system. When a control signal is sent, compressed air moves the actuator piston, lifting the valve plug from the angled seat to allow fluid to flow. The intelligent positioning module continuously monitors and adjusts the valve position to maintain precise flow rates. Closing the valve reverses the actuator motion, pressing the plug firmly against the seat for a tight seal. The angled seat design ensures smooth flow, minimal pressure loss, and hygienic operation, making it suitable for automated sanitary processes requiring accurate fluid control

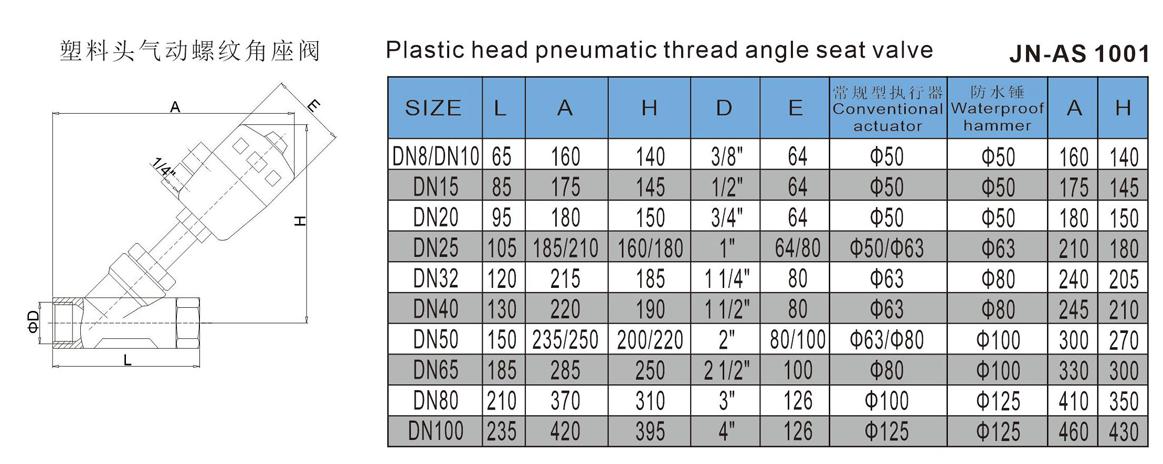

Specification Chart

Max Working Pressure | 1.6MPa |

Medium Temperature | -10℃~+180℃ |

Ambient Temperature | -10℃~+55℃ |

Body Materials | CF8M(SS316),CF8(SS304) |

Sealing Material | PTFE |

Operation | Normally Closed, Normally Open, Double-acting or Manually |

Connection End | Female, Weld,Clamp, Flange or on request |

Size Range | DN10-DN100 |

Surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Standards | DIN, SMS, ISO / IDF, BS / RJT, ASME / BPE. |

Control type | Single acting, double acting |

Features

Constructed from high-quality stainless steel, ensuring corrosion resistance, durability, and suitability for hygienic processing environments.

Pneumatic actuator with intelligent positioning provides precise, automated control of fluid flow for consistent process performance.

Angle seat design ensures smooth flow, reduces pressure loss, and supports efficient discharge in sanitary piping systems.

Hygienic polished surfaces and tight sealing prevent leakage, enabling clean-in-place (CIP) and sterilize-in-place (SIP) operations.

Compatible with control systems, offering real-time position feedback for accurate monitoring and integration into automated production lines

Application

Stainless Steel Sanitary Pneumatic Intelligent Positioning Angle Seat Valves are widely used in pharmaceutical and biotechnology industries for precise, automated control of sterile liquids in production lines. They are also applied in food and beverage manufacturing for controlling flow during mixing, filling, or heating processes. The combination of pneumatic actuation and intelligent positioning ensures accurate flow regulation, hygienic operation, and seamless integration into automated systems, making them suitable for industries requiring high precision, sanitary standards, and reliable process control