| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless Steel Sanitary Pneumatic Split Rotary Butterfly Valve

The Stainless Steel Sanitary Pneumatic Split Rotary Butterfly Valve is an automated valve designed for hygienic flow control. Its split rotary disc allows precise modulation, while the pneumatic actuator enables fast, reliable operation in food, pharmaceutical, and biotechnology processing systems

Working Principles

Stainless Steel Sanitary Pneumatic Split Rotary Butterfly Valve operates using a pneumatic actuator to control a split rotary disc mounted on a central shaft. When compressed air is applied, the actuator rotates the disc to align with the pipeline, allowing fluid to pass, or rotates it perpendicular to stop flow. The split rotary design ensures smooth modulation, reducing pressure fluctuations and enabling precise flow control. Seals around the disc provide leak-free operation while maintaining hygienic standards. Its stainless steel construction and sanitary design minimize dead space, prevent contamination, and support cleaning-in-place (CIP) procedures, making it ideal for food, pharmaceutical, and biotech applications

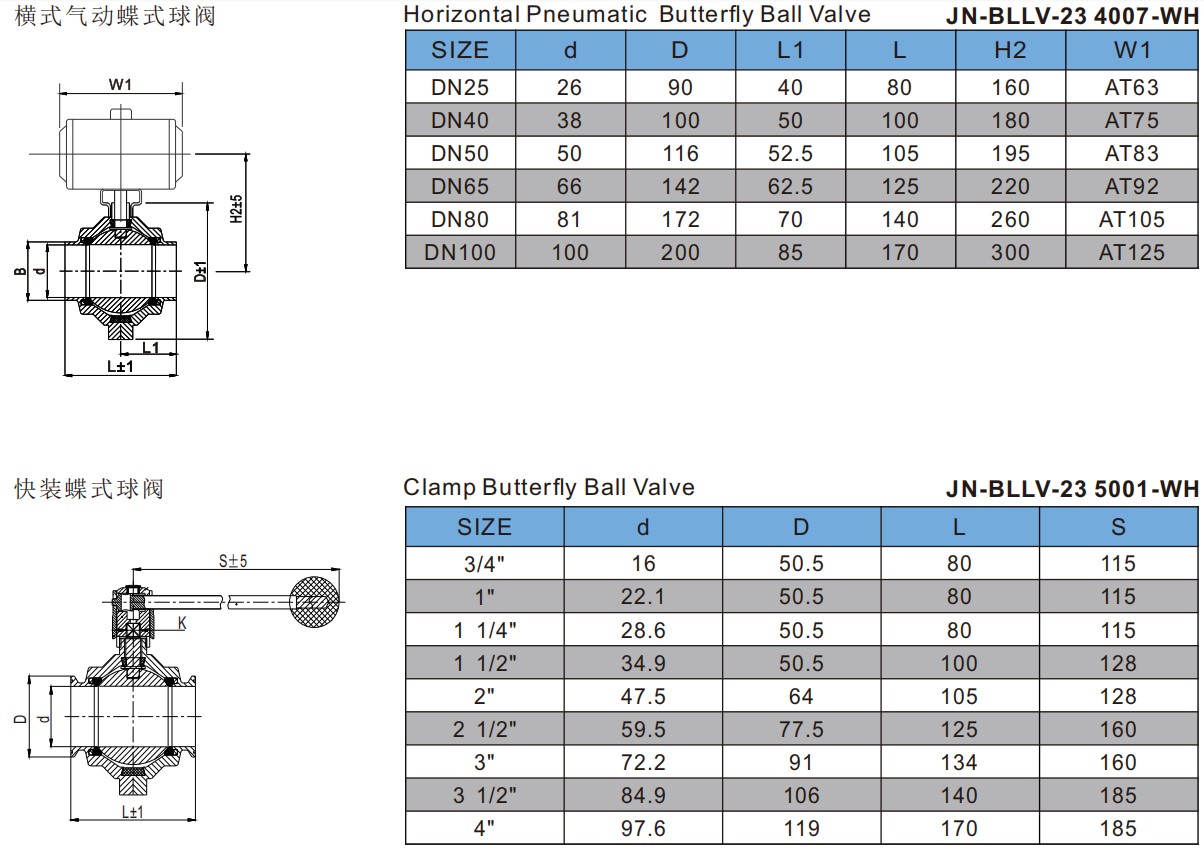

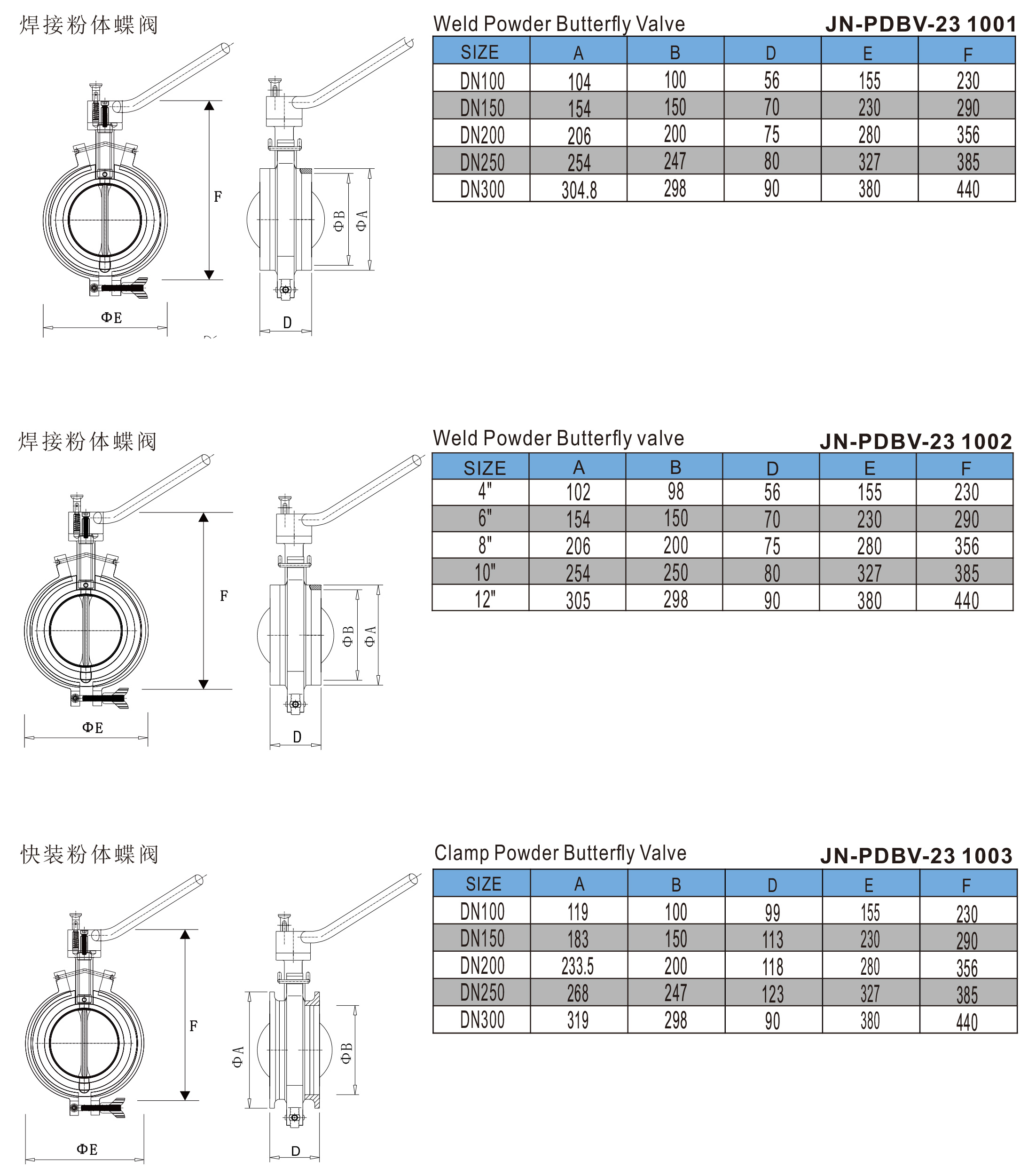

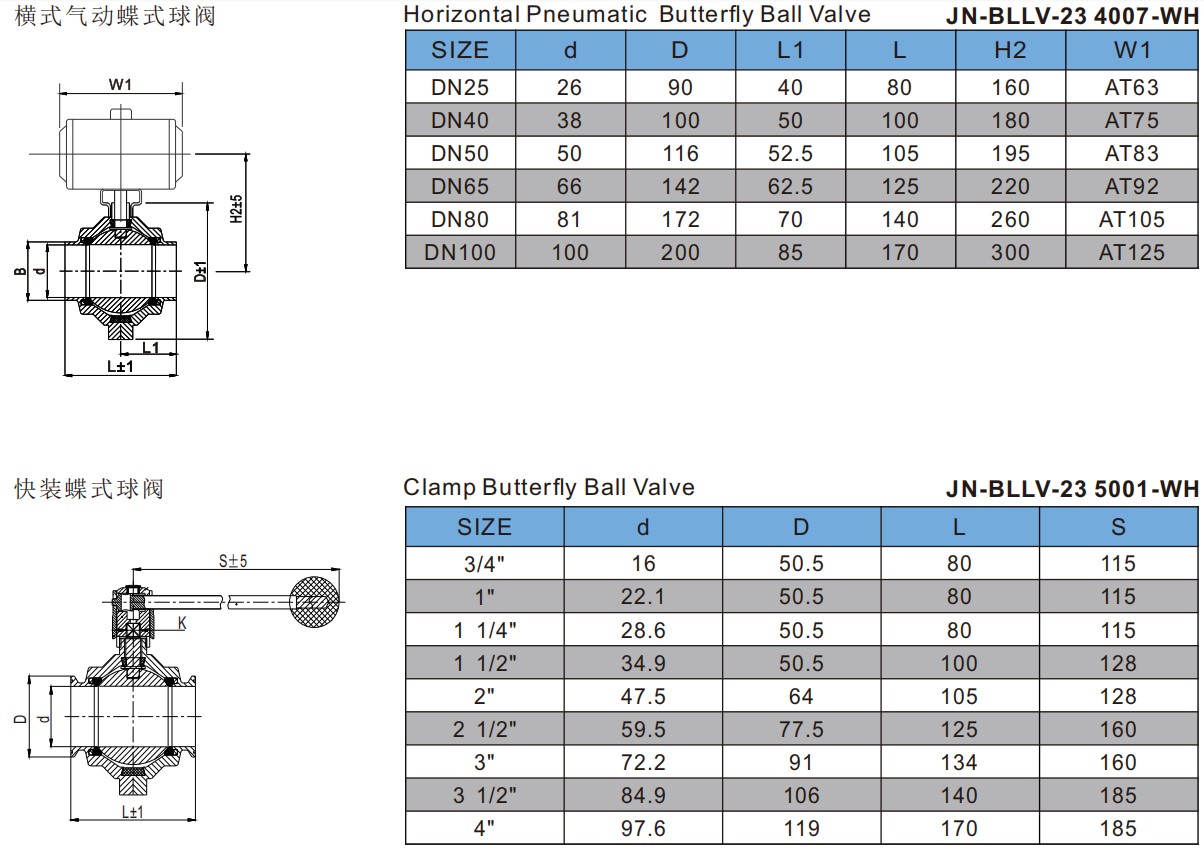

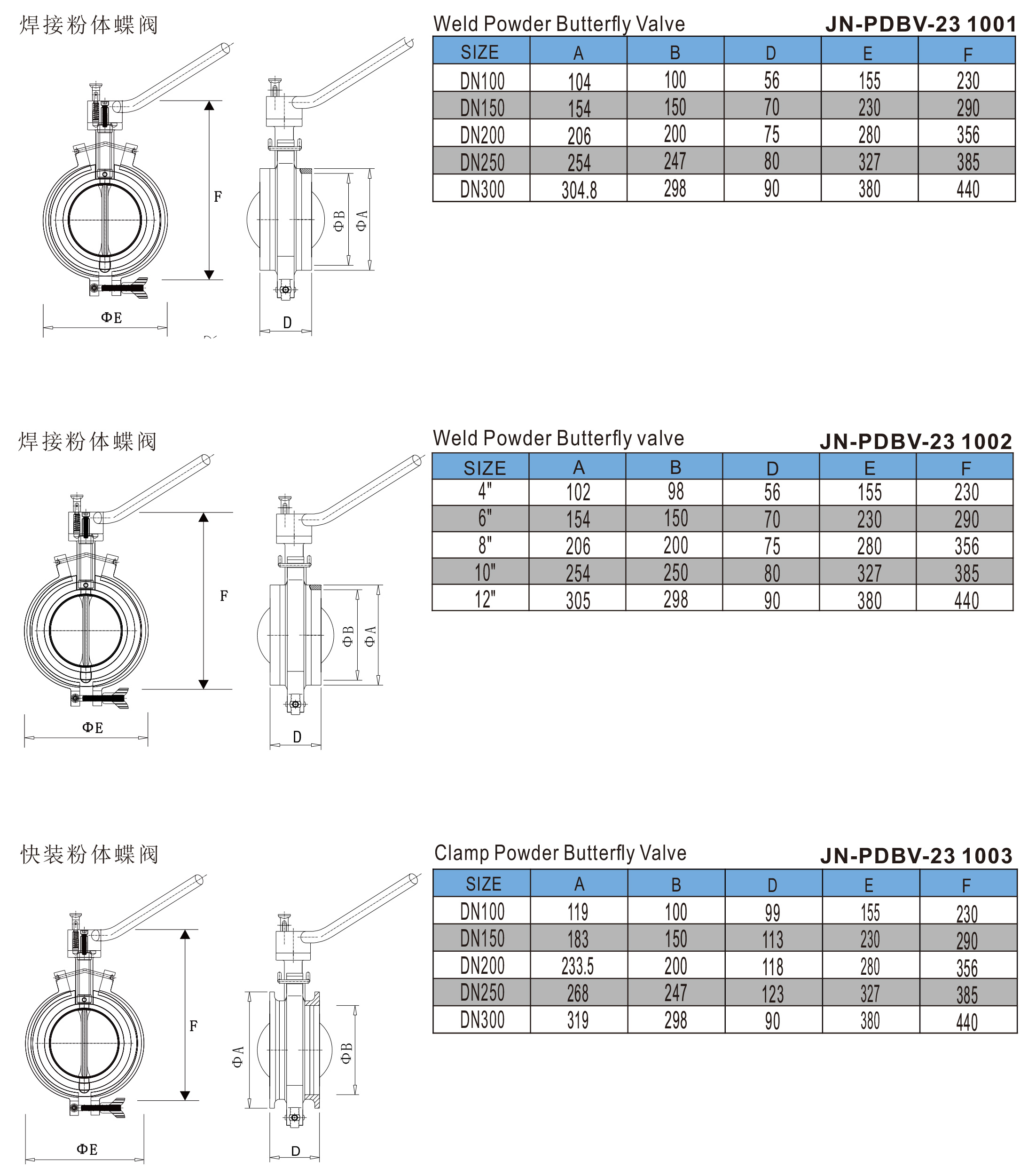

Stainless Steel Butterfly Valve Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Features

Pneumatic Actuation – Provides fast, automated operation for precise flow control, reducing manual intervention and improving process efficiency.

Split Rotary Disc Design – Ensures smooth, stable flow modulation with minimal pressure drop and accurate control.

Stainless Steel Construction – Durable and corrosion-resistant, suitable for hygienic and high-purity applications.

Leak-Free Sealing – Precision-engineered seats ensure reliable shutoff and maintain sanitary integrity.

Sanitary Surface Finish – Smooth, crevice-free interior surfaces support cleaning-in-place (CIP) and minimize contamination risks.

Compact and Versatile – Space-saving design allows easy installation in pipelines and integration with automated systems

Application

The Stainless Steel Sanitary Pneumatic Split Rotary Butterfly Valve is widely used in industries requiring precise, automated, and hygienic flow control. Typical applications include beverage production for controlled liquid distribution, pharmaceutical manufacturing for sterile fluid handling, biotechnology for media transfer, and food processing where contamination-free, accurate flow regulation is essential

Working Principles

The Stainless Steel Sanitary Pneumatic Split Rotary Butterfly Valve operates using a pneumatic actuator to control a split rotary disc mounted on a central shaft. When compressed air is applied, the actuator rotates the disc to align with the pipeline, allowing fluid to pass, or rotates it perpendicular to stop flow. The split rotary design ensures smooth modulation, reducing pressure fluctuations and enabling precise flow control. Seals around the disc provide leak-free operation while maintaining hygienic standards. Its stainless steel construction and sanitary design minimize dead space, prevent contamination, and support cleaning-in-place (CIP) procedures, making it ideal for food, pharmaceutical, and biotech applications

Feature and Specification

Stainless Steel Butterfly Valve Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Features

Pneumatic Actuation – Provides fast, automated operation for precise flow control, reducing manual intervention and improving process efficiency.

Split Rotary Disc Design – Ensures smooth, stable flow modulation with minimal pressure drop and accurate control.

Stainless Steel Construction – Durable and corrosion-resistant, suitable for hygienic and high-purity applications.

Leak-Free Sealing – Precision-engineered seats ensure reliable shutoff and maintain sanitary integrity.

Sanitary Surface Finish – Smooth, crevice-free interior surfaces support cleaning-in-place (CIP) and minimize contamination risks.

Compact and Versatile – Space-saving design allows easy installation in pipelines and integration with automated systems

Application

The Stainless Steel Sanitary Pneumatic Split Rotary Butterfly Valve is widely used in industries requiring precise, automated, and hygienic flow control. Typical applications include beverage production for controlled liquid distribution, pharmaceutical manufacturing for sterile fluid handling, biotechnology for media transfer, and food processing where contamination-free, accurate flow regulation is essential