| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary butt-weld ferrule fitting is a pipe connector that combines butt-welding technology and ferrule design, and is usually used in industrial piping systems that require high sanitation requirements. The stainless steel sanitary butt-weld ferrule fitting is usually used in piping systems in industries such as food, beverages, and pharmaceuticals, especially pipes that require high sanitation, pressure resistance, and corrosion resistance. It is mostly used for straight connections, branches, corners, or interface locations with other equipment. Common types of stainless steel sanitary butt-weld ferrule fittings include: straight-through butt-weld ferrule fittings, elbow butt-weld ferrule fittings, tee butt-weld ferrule fittings, flange butt-weld ferrule fittings, and reducing butt-weld ferrule fittings.

JONENG

8421219990

Stainless Steel Sanitary Quick Clamping Butt Welding Ferrule Fittings

The stainless steel sanitary butt-weld ferrule fitting is designed to provide a sealed and stable pipe connection solution under extreme sanitary conditions. It combines the advantages of butt-welding technology and ferrules to prevent leakage and corrosion while keeping the piping system hygienic and safe. This fitting is particularly suitable for industries with extremely high pressure, temperature, and sanitation requirements, such as food, beverages, and pharmaceuticals. By ensuring the perfect seal of each connection point, avoiding material residue and contamination, the fluid quality and long-term reliability of the system are maintained to the greatest extent.

Working Principles

The working principle of the stainless steel sanitary butt-weld ferrule fitting is based on the dual effects of butt welding and ferrule. First, the two ends of the pipe are connected by butt welding to ensure that the joint area has sufficient strength and sealing. After welding, the ferrule part is installed on the outside of the pipe, and the fitting is firmly fixed to the pipe by the tightening action of the ferrule. The design of the ferrule provides additional sealing force to ensure that there is no leakage between the pipes.

The options of the stainless steel sanitary butt-weld ferrule fitting include:

Material: 304, 316L stainless steel, suitable for different corrosive environments.

Connection method: butt welding, ferrule fixing.

Size: customized according to the pipe diameter.

Surface treatment: mirror polishing, matte polishing.

Sealing method: O-ring sealing, flat sealing.

Type: straight, elbow, tee, etc.

Pressure level: choose different pressure levels according to system requirements.

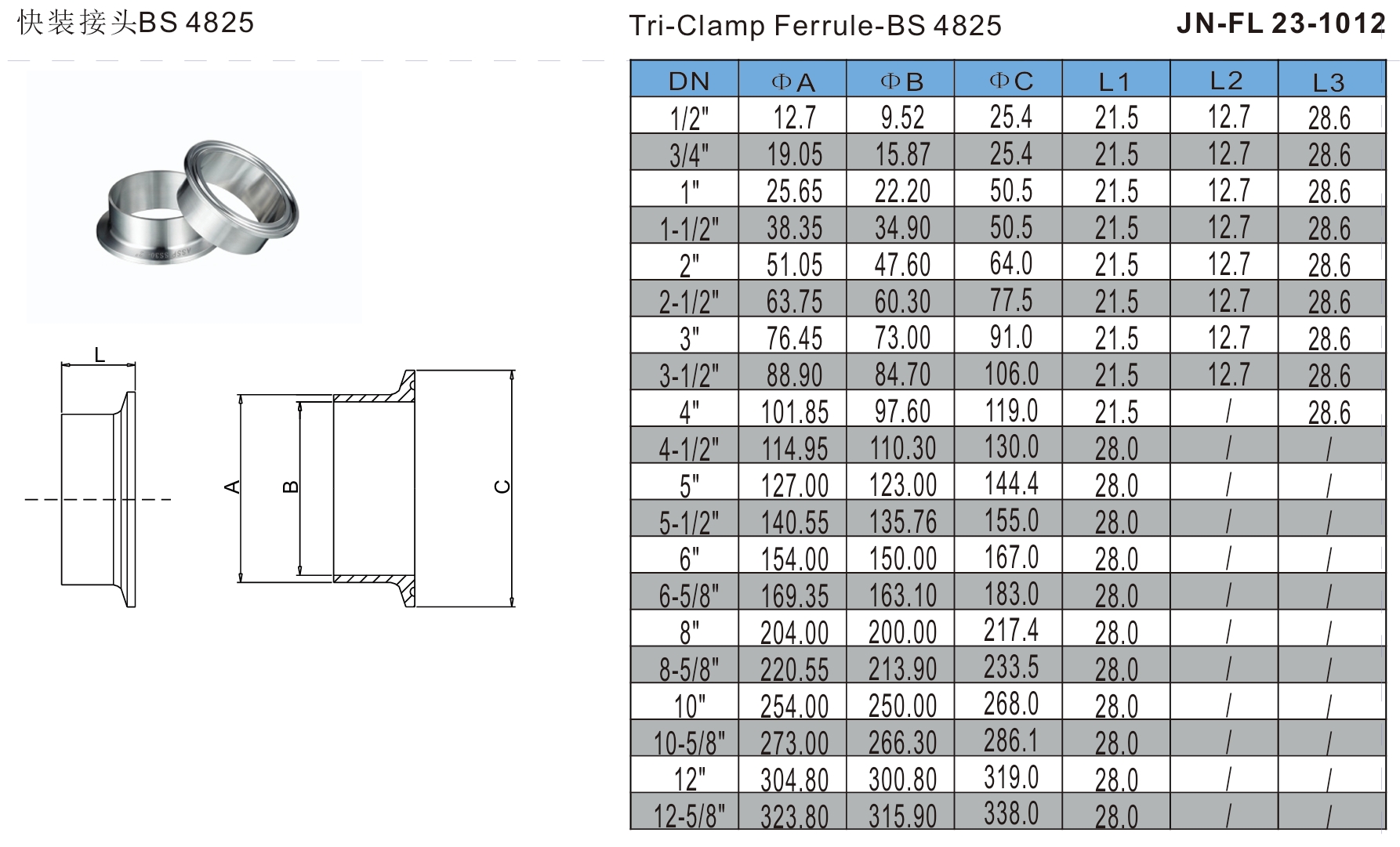

Specification Chart

Material | ASI304, 316L |

Size | ½ “ to 12” |

Gaskets or seals | Silicone, EPDM, Viton,NBR.. |

Pressure | 6 to 20 bars |

Temperature | 20C to 150C |

Standard | SMS, DIN, 3A,RJT,BSM,IDF.. |

Features

● The stainless steel sanitary butt-weld ferrule joint is designed with a tiny bending effect inside the joint, which can optimize fluid flow and reduce friction and pressure loss.

● During the welding process, the inside and outside of the stainless steel sanitary butt-weld ferrule joint are welded to ensure strength and sealing.

● During the cooling process after welding, the stainless steel sanitary butt-weld ferrule joint controls the shrinkage stress in the joint through a special cooling method.

● The stainless steel sanitary butt-weld ferrule joint has a gradual design of the sealing surface of the joint, so that the sealing force is self-enhanced as the pipeline pressure increases.

● The stainless steel sanitary butt-weld ferrule joint uses laser to accurately control the welding temperature area to ensure uniform local temperature distribution and reduce thermal damage.

● The stainless steel sanitary butt-weld ferrule joint is coated with an anti-oxidation coating on the inner wall of the welded joint to prevent oxidation reactions at high temperatures.

Application

Stainless steel sanitary butt-welding ferrule joints are widely used in the following industries: Food industry: used in production lines such as beverages, dairy products, and juices to ensure that the pipeline system meets hygiene requirements and avoids contamination of products. Pharmaceutical industry: used to ensure a sterile environment and avoid contamination of drugs during the production and transmission of drugs. Cosmetics industry: used to transport raw materials and finished products in the production process of cosmetics to ensure product quality and hygiene. Bioengineering: used in biopharmaceuticals and fermentation processes to ensure that fluid transportation is not contaminated and meets GMP standards. Beverage industry: used for pipeline connections in the production process of beer, beverages, etc. to ensure hygiene and quality control. Chemical industry: used to transport chemical raw materials, solvents and other fluids to ensure the sealing and corrosion resistance of pipeline connections.

Working Principles

The working principle of the stainless steel sanitary butt-weld ferrule fitting is based on the dual effects of butt welding and ferrule. First, the two ends of the pipe are connected by butt welding to ensure that the joint area has sufficient strength and sealing. After welding, the ferrule part is installed on the outside of the pipe, and the fitting is firmly fixed to the pipe by the tightening action of the ferrule. The design of the ferrule provides additional sealing force to ensure that there is no leakage between the pipes.

The options of the stainless steel sanitary butt-weld ferrule fitting include:

Material: 304, 316L stainless steel, suitable for different corrosive environments.

Connection method: butt welding, ferrule fixing.

Size: customized according to the pipe diameter.

Surface treatment: mirror polishing, matte polishing.

Sealing method: O-ring sealing, flat sealing.

Type: straight, elbow, tee, etc.

Pressure level: choose different pressure levels according to system requirements.

Specification Chart

Material | ASI304, 316L |

Size | ½ “ to 12” |

Gaskets or seals | Silicone, EPDM, Viton,NBR.. |

Pressure | 6 to 20 bars |

Temperature | 20C to 150C |

Standard | SMS, DIN, 3A,RJT,BSM,IDF.. |

Features

● The stainless steel sanitary butt-weld ferrule joint is designed with a tiny bending effect inside the joint, which can optimize fluid flow and reduce friction and pressure loss.

● During the welding process, the inside and outside of the stainless steel sanitary butt-weld ferrule joint are welded to ensure strength and sealing.

● During the cooling process after welding, the stainless steel sanitary butt-weld ferrule joint controls the shrinkage stress in the joint through a special cooling method.

● The stainless steel sanitary butt-weld ferrule joint has a gradual design of the sealing surface of the joint, so that the sealing force is self-enhanced as the pipeline pressure increases.

● The stainless steel sanitary butt-weld ferrule joint uses laser to accurately control the welding temperature area to ensure uniform local temperature distribution and reduce thermal damage.

● The stainless steel sanitary butt-weld ferrule joint is coated with an anti-oxidation coating on the inner wall of the welded joint to prevent oxidation reactions at high temperatures.

Application

Stainless steel sanitary butt-welding ferrule joints are widely used in the following industries: Food industry: used in production lines such as beverages, dairy products, and juices to ensure that the pipeline system meets hygiene requirements and avoids contamination of products. Pharmaceutical industry: used to ensure a sterile environment and avoid contamination of drugs during the production and transmission of drugs. Cosmetics industry: used to transport raw materials and finished products in the production process of cosmetics to ensure product quality and hygiene. Bioengineering: used in biopharmaceuticals and fermentation processes to ensure that fluid transportation is not contaminated and meets GMP standards. Beverage industry: used for pipeline connections in the production process of beer, beverages, etc. to ensure hygiene and quality control. Chemical industry: used to transport chemical raw materials, solvents and other fluids to ensure the sealing and corrosion resistance of pipeline connections.