| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary round manhole is a special equipment opening device, mainly used to close or open the inspection port of a tank, pipeline or reactor. The stainless steel sanitary round manhole is usually used in key positions of liquid, gas or powder conveying pipelines, especially in occasions where regular maintenance, cleaning, sampling or replacement of internal components is required. It is widely used in closed systems such as storage tanks, reactors, pressure vessels, steam systems, etc. There are mainly the following types of stainless steel sanitary round manholes: standard manhole, manhole with observation window, pressurized manhole, manhole with airtight seal, quick opening and closing manhole, adjustable manhole.

JONENG

8421219990

Stainless Steel Sanitary Quick-open Bolt Round Tank Cover Manhole

The stainless steel sanitary round manhole is designed to achieve efficient access and operation of closed equipment while ensuring strict hygiene standards. Its unique circular structure makes installation and sealing more stable and reliable, and can effectively prevent external contamination from entering. The design of the manhole can provide the convenience of rapid internal inspection, cleaning, sampling and maintenance of the equipment, while avoiding leakage and contamination, and meets the strict hygiene requirements of the pharmaceutical, food and other industries. Through precise sealing technology, the safety of the medium in the production process is ensured, the entry of microorganisms or foreign substances is prevented, and the potential risk of cross contamination is greatly reduced. This design is particularly suitable for processes that require extremely high cleanliness and aseptic environment, such as liquid food, pharmaceutical and biological product production.

Working Principles

The working principle of the stainless steel sanitary round manhole is mainly based on its sealing structure and convenient operation design. First, the round manhole is connected to the container or pipeline through a fixed frame to ensure firmness and stability. The sealing gasket ensures a high degree of airtightness and liquid tightness when the manhole is closed to prevent contaminants from entering. When opening, the operator opens the manhole cover by quickly opening or unlocking the device to connect its inner cavity to the external environment. After the operation is completed, the cover is re-covered and locked again by the sealing device to restore the sealing of the equipment and prevent external contamination.

The options of the stainless steel sanitary round manhole include:

Material: 304 or 316L stainless steel to meet different corrosion resistance requirements.

Size: A variety of diameter specifications, suitable for different containers or pipelines.

Sealing material: EPDM, silicone or PTFE, suitable for different media and temperatures.

Surface treatment: electrolytic polishing or mirror polishing to improve the hygiene level.

Opening method: quick-open bolt, clamp or hinge design.

Pressure level: normal pressure or high pressure design to meet different working conditions.

Additional functions: with sight glass, cleaning ball or exhaust port.

Certification standard: in line with international hygiene certifications such as 3A, FDA, EHEDG, etc.

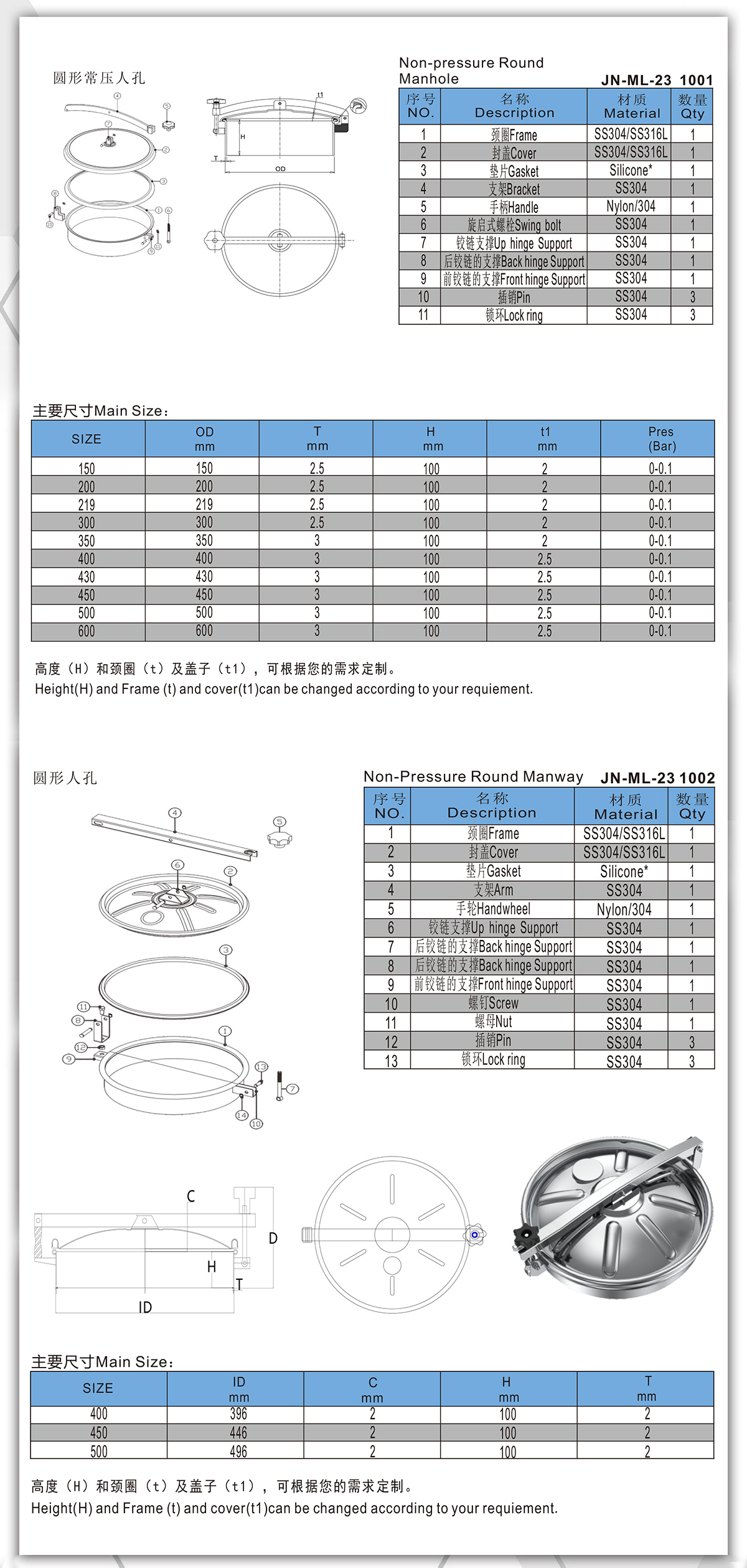

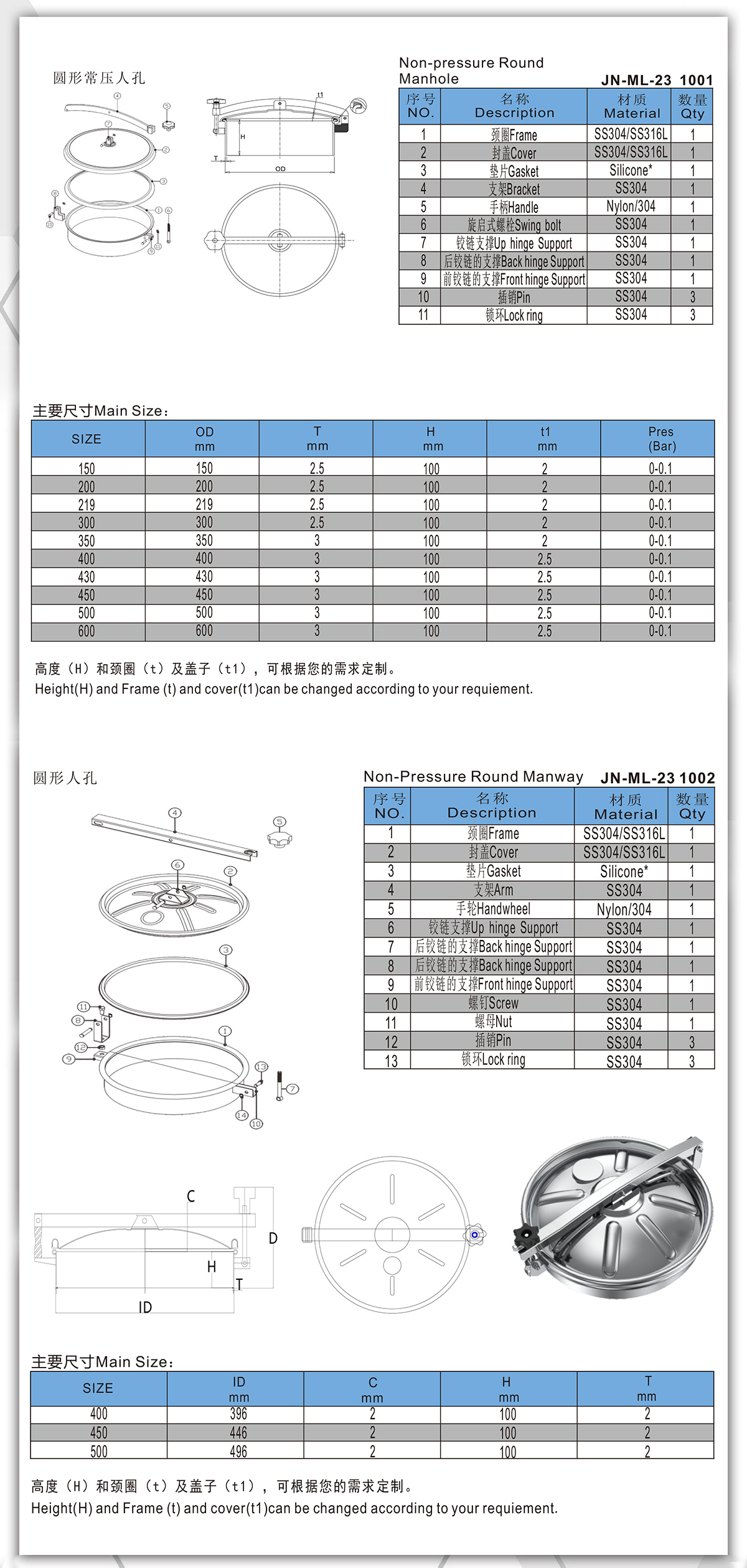

Specification Chart

Size | 200 to 600 mm |

Material | AISI304, AISI316L |

Seal | EPDM, PTFE, silicon |

Height | 100,120,150mm |

Maximum pressure | 10 bar |

Temperature range | -10 °C ~ 120 °C |

Features

● The stainless steel sanitary round manhole cover has a built-in magnetic sealing ring, which enhances the sealing effect through magnetic force to ensure zero leakage under vibration or pressure fluctuations.

● The stainless steel sanitary round manhole adopts a mechanical self-locking design. No tools are required when opening, and it can be completed with one-handed operation. It automatically locks when closed to prevent accidental opening.

● The inner wall of the stainless steel sanitary round manhole is coated with nano-level antibacterial material to inhibit the growth of microorganisms, which is particularly suitable for sterile or high-cleanliness environments.

● The stainless steel sanitary round manhole is integrated with a dual-channel exhaust valve to ensure that the internal pressure is quickly balanced when opening to avoid medium splashing or vacuum adsorption.

● The stainless steel sanitary round manhole adopts ultra-low temperature compatible sealing materials and anti-cold brittle stainless steel, which can operate stably in a -50℃ environment and is suitable for freezing projects.

● The stainless steel sanitary round manhole cover is designed with a silencer gasket on the contact surface with the flange to reduce the metal collision noise when opening and closing.

Application

Stainless steel sanitary round manholes are widely used in the following industries: Food industry: used for inspection and cleaning of storage tanks and pipelines to ensure hygiene. Pharmaceutical industry: meets the equipment maintenance needs in a sterile environment. Bioengineering: suitable for internal operations of high-cleanliness containers. Cosmetics industry: ensures the sanitation and safety of raw material storage and production. Chemical industry: corrosion-resistant, suitable for chemical storage tank inspection. Brewing industry: used for fermentation tank cleaning and maintenance operations. Environmental protection industry: treatment of high-purity water and wastewater storage tank maintenance.

Working Principles

The fundamental working principle revolves around maintaining the integrity of pressure vessels and preventing the release of high pressure substances. These covers play a vital role in safeguarding both the equipment and for the personnel work around pressure vessels industries.

Specification Chart

Size | 200 to 600 mm |

Material | AISI304, AISI316L |

Seal | EPDM, PTFE, silicon |

Height | 100,120,150mm |

Maximum pressure | 10 bar |

Temperature range | -10 °C ~ 120 °C |

Features

●Safety, durability

●Access for maintenance

●Pressure contaminant

●Airtight sealing

●Versatility, risk reduction

Application

The primary application is in industries like food and beverage, chemical processing plant, pharmaceutical, biotechnology and other industries.