| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary circular pipe bracket is a structural part specially used to fix and support sanitary circular pipes, with high stability and corrosion resistance. The stainless steel sanitary circular pipe bracket is usually installed at key positions such as the support points, corners, connection nodes and vertical sections of the pipe to stabilize the suspended pipe to prevent sagging or shaking due to gravity or fluid impact; it is installed at corners and intersections to disperse stress and avoid fatigue damage caused by bending or vibration. Common types of stainless steel sanitary circular pipe brackets include: quick-install pipe brackets, welded pipe brackets, threaded fixed pipe brackets, shockproof pipe brackets, double-ring pipe brackets, and hanging pipe brackets.

JONENG

8481804090

Stainless Steel Sanitary Round Pipe Bracket For Medical Use

The design purpose of the stainless steel sanitary circular pipe bracket is not only to fix the pipe, but also to optimize the long-term stability of the pipe system and reduce fatigue damage caused by small displacements. It can disperse the thermal expansion and contraction stress caused by temperature changes in the pipe, and prevent microcrack expansion or sealing failure due to long-term stress concentration. In addition, it can reduce the resonance effect caused by turbulence or pulsating pressure during fluid transportation, and avoid equipment damage or noise pollution caused by resonance. In special environments, such as clean rooms or ultra-low temperature conditions, the bracket can also provide additional insulation protection, reduce the adhesion of condensed water, thereby reducing the risk of microbial growth and ensuring the sterility and safety of the production environment.

Working Principles

The working principle of the stainless steel sanitary round pipe bracket is based on four core functions: stable support, shock absorption and buffering, stress dispersion and anti-corrosion protection. First, the bracket body is fixed to the wall, ground or supporting structure by bolts, welding or quick-installation to ensure overall stability. Subsequently, the pipe is placed in the clamping part of the bracket and fastened by clamps, bolts or quick-install clamps to stabilize the pipe position and avoid loosening or displacement. During the operation of the pipeline, the embedded shock-absorbing gasket or shock-proof layer can absorb the impact force caused by fluid flow, equipment vibration or environmental factors, reduce resonance, and reduce wear between the pipe and the bracket.

The options of the stainless steel sanitary round pipe bracket include:

Material: 304 or 316 stainless steel, 316 is more corrosion-resistant.

Surface treatment: polished, brushed or passivated to meet different hygiene and aesthetic requirements.

Connection method: welding, clamp or threaded connection to meet different installation requirements.

Size: various diameters and lengths to match different pipe or equipment specifications.

Load-bearing capacity: light load, medium load or heavy load design to meet different load requirements.

Additional functions: adjustable height, angle or shockproof design to enhance applicability.

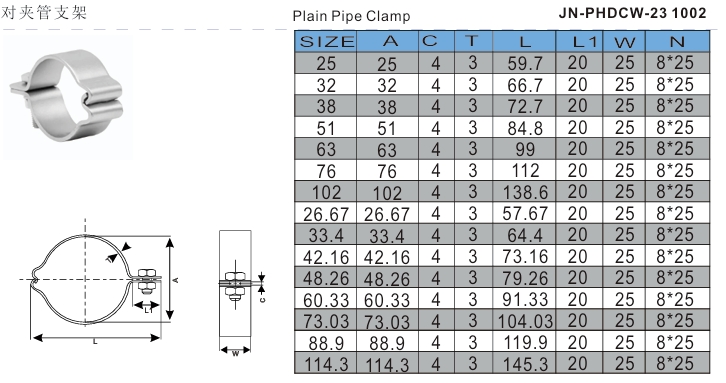

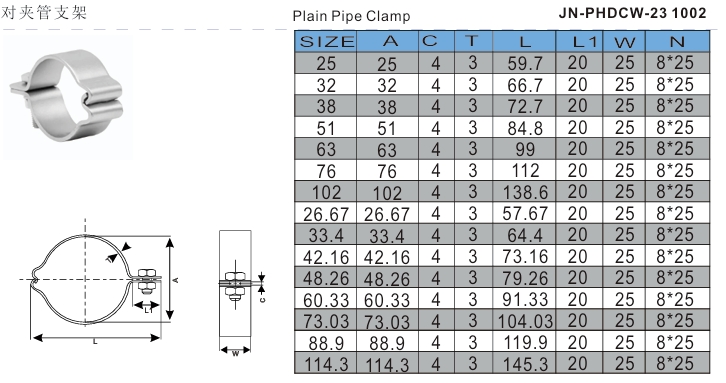

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The contact part between the stainless steel sanitary round tube bracket and the pipeline adopts a streamlined transition to reduce eddy currents and dust accumulation, and reduce the risk of microbial breeding.

● The stainless steel sanitary round tube bracket is embedded with a polymer elastic material such as PTFE or silicone layer to absorb vibration and noise.

● The stainless steel sanitary round tube bracket adopts seamless welding and overall stretching forming process, so that the bracket will not break or corrode due to weld defects when it is stressed.

● The stainless steel sanitary round tube bracket is designed with a structure that can slide or retract slightly, which can adapt to the thermal expansion and contraction of the pipeline due to temperature changes, and avoid deformation or breakage of the pipeline fixing point due to stress concentration.

● The stainless steel sanitary round tube bracket adopts a nano-level anti-fouling coating to effectively reduce dust, oil stains or liquid adhesion and keep it clean for a long time.

● The stainless steel sanitary round tube bracket adopts a double-layer clamping design, which enhances the fixing force through the inner and outer layer clamping method to avoid local uneven force caused by single-point fixation.

Application

Stainless steel sanitary round pipe brackets are widely used in the following industries: Food industry: ensure pipeline stability, prevent pollution, and meet hygiene standards. Pharmaceutical industry: support pipelines, avoid vibration and pollution, and ensure a sterile environment. Bioengineering: ensure pipeline fixation and adapt to high cleanliness and special process requirements. Chemical industry: Strong corrosion resistance, suitable for piping systems in harsh chemical environments. Beverage industry: Ensure the stability of production line pipelines to avoid affecting product quality. Medical industry: Ensure pipeline stability, reduce vibration, and meet strict hygiene requirements. Cosmetics industry: Avoid pipeline failure due to vibration or thermal expansion and contraction, and ensure cleanliness.

Working Principles

The working principle of the stainless steel sanitary round pipe bracket is based on four core functions: stable support, shock absorption and buffering, stress dispersion and anti-corrosion protection. First, the bracket body is fixed to the wall, ground or supporting structure by bolts, welding or quick-installation to ensure overall stability. Subsequently, the pipe is placed in the clamping part of the bracket and fastened by clamps, bolts or quick-install clamps to stabilize the pipe position and avoid loosening or displacement. During the operation of the pipeline, the embedded shock-absorbing gasket or shock-proof layer can absorb the impact force caused by fluid flow, equipment vibration or environmental factors, reduce resonance, and reduce wear between the pipe and the bracket.

The options of the stainless steel sanitary round pipe bracket include:

Material: 304 or 316 stainless steel, 316 is more corrosion-resistant.

Surface treatment: polished, brushed or passivated to meet different hygiene and aesthetic requirements.

Connection method: welding, clamp or threaded connection to meet different installation requirements.

Size: various diameters and lengths to match different pipe or equipment specifications.

Load-bearing capacity: light load, medium load or heavy load design to meet different load requirements.

Additional functions: adjustable height, angle or shockproof design to enhance applicability.

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The contact part between the stainless steel sanitary round tube bracket and the pipeline adopts a streamlined transition to reduce eddy currents and dust accumulation, and reduce the risk of microbial breeding.

● The stainless steel sanitary round tube bracket is embedded with a polymer elastic material such as PTFE or silicone layer to absorb vibration and noise.

● The stainless steel sanitary round tube bracket adopts seamless welding and overall stretching forming process, so that the bracket will not break or corrode due to weld defects when it is stressed.

● The stainless steel sanitary round tube bracket is designed with a structure that can slide or retract slightly, which can adapt to the thermal expansion and contraction of the pipeline due to temperature changes, and avoid deformation or breakage of the pipeline fixing point due to stress concentration.

● The stainless steel sanitary round tube bracket adopts a nano-level anti-fouling coating to effectively reduce dust, oil stains or liquid adhesion and keep it clean for a long time.

● The stainless steel sanitary round tube bracket adopts a double-layer clamping design, which enhances the fixing force through the inner and outer layer clamping method to avoid local uneven force caused by single-point fixation.

Application

Stainless steel sanitary round pipe brackets are widely used in the following industries: Food industry: ensure pipeline stability, prevent pollution, and meet hygiene standards. Pharmaceutical industry: support pipelines, avoid vibration and pollution, and ensure a sterile environment. Bioengineering: ensure pipeline fixation and adapt to high cleanliness and special process requirements. Chemical industry: Strong corrosion resistance, suitable for piping systems in harsh chemical environments. Beverage industry: Ensure the stability of production line pipelines to avoid affecting product quality. Medical industry: Ensure pipeline stability, reduce vibration, and meet strict hygiene requirements. Cosmetics industry: Avoid pipeline failure due to vibration or thermal expansion and contraction, and ensure cleanliness.