| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless Steel Sanitary Rubbe Manual Water Diaphragm Valve

The Stainless Steel Sanitary Rubber Manual Water Diaphragm Valve is a hand-operated valve designed for sanitary water control. Its rubber-lined diaphragm ensures leak-free operation, smooth flow, and corrosion resistance, making it suitable for food, beverage, pharmaceutical, and high-purity water systems.

Working Principles

The Stainless Steel Sanitary Rubber Manual Water Diaphragm Valve operates by manually turning a handwheel or lever to move a stem connected to a flexible rubber diaphragm. As the diaphragm presses down onto the valve seat, it blocks the flow of water, creating a tight, leak-free seal. Lifting the diaphragm opens the flow path, allowing water to pass through smoothly. The rubber lining provides corrosion resistance and isolates the fluid from the metal valve body, ensuring hygienic operation. This manual mechanism allows precise flow control and reliable shutoff, making the valve suitable for sanitary water systems in food, beverage, and pharmaceutical applications.

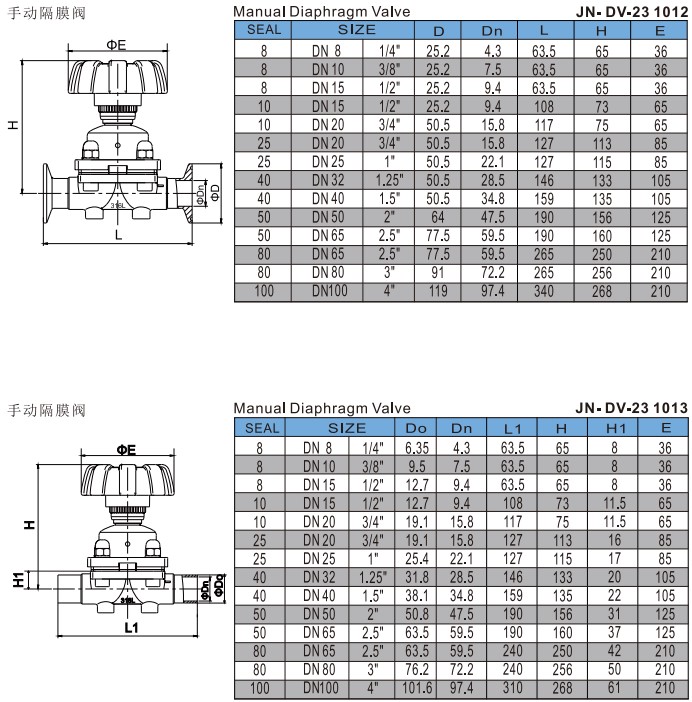

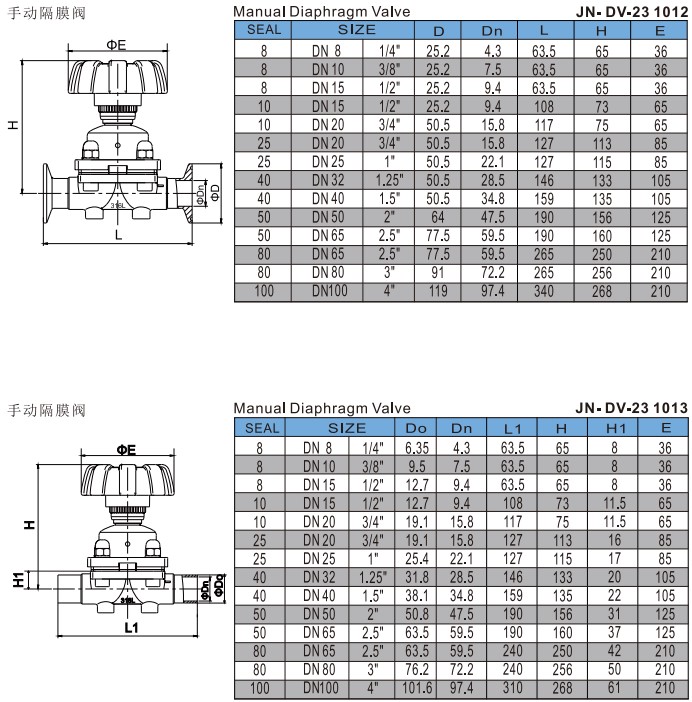

Stainless Steel Diaphragm Valve Specification Chart

Body Material | Stainless Steel 304 / 316L |

Valve Type | Manual Diaphragm Valve |

Diaphragm Material | EPDM / NBR / FDA-compliant Rubber |

Operation Mode | Handwheel or Lever Manual Operation |

Connection Style | Clamp, Welded, or Threaded Sanitary Connections |

Typical Industries | Food and beverage, pharmaceutical, biotechnology, and high-purity water systems |

Design Standard | Sanitary / Hygienic Valve Standards |

Working Pressure | ≤ 10 bar (varies by size and lining) |

Working Temperature | 0°C to 100°C (depending on rubber type) |

Surface Finish | Ra ≤ 0.8 μm (internal), sanitary polished |

Features

Rubber Diaphragm Seal – Provides leak-free shutoff and isolates fluid from mechanical parts, ensuring hygienic operation and corrosion resistance.

Manual Operation – Handwheel or lever allows precise control over water flow without requiring external power.

Stainless Steel Body – Durable, corrosion-resistant, and suitable for sanitary applications in food, beverage, pharmaceutical, and water systems.

Hygienic Design – Smooth, crevice-free surfaces reduce contamination risk and support easy cleaning and maintenance.

Versatile Connections – Supports clamp, welded, or threaded ends for easy integration into various pipeline systems.

Reliable Performance – Ensures consistent flow control, durable sealing, and long service life in high-purity water applications.

Application

The Stainless Steel Sanitary Rubber Manual Water Diaphragm Valve is used in industries requiring safe and hygienic water handling. Typical applications include beverage production, dairy processing, pharmaceutical water systems, laboratory water distribution, and clean-in-place (CIP) circuits, where reliable, leak-free flow control is essential.

Working Principles

The Stainless Steel Sanitary Rubber Manual Water Diaphragm Valve operates by manually turning a handwheel or lever to move a stem connected to a flexible rubber diaphragm. As the diaphragm presses down onto the valve seat, it blocks the flow of water, creating a tight, leak-free seal. Lifting the diaphragm opens the flow path, allowing water to pass through smoothly. The rubber lining provides corrosion resistance and isolates the fluid from the metal valve body, ensuring hygienic operation. This manual mechanism allows precise flow control and reliable shutoff, making the valve suitable for sanitary water systems in food, beverage, and pharmaceutical applications.

Stainless Steel Diaphragm Valve Specification Chart

Body Material | Stainless Steel 304 / 316L |

Valve Type | Manual Diaphragm Valve |

Diaphragm Material | EPDM / NBR / FDA-compliant Rubber |

Operation Mode | Handwheel or Lever Manual Operation |

Connection Style | Clamp, Welded, or Threaded Sanitary Connections |

Typical Industries | Food and beverage, pharmaceutical, biotechnology, and high-purity water systems |

Design Standard | Sanitary / Hygienic Valve Standards |

Working Pressure | ≤ 10 bar (varies by size and lining) |

Working Temperature | 0°C to 100°C (depending on rubber type) |

Surface Finish | Ra ≤ 0.8 μm (internal), sanitary polished |

Features

Rubber Diaphragm Seal – Provides leak-free shutoff and isolates fluid from mechanical parts, ensuring hygienic operation and corrosion resistance.

Manual Operation – Handwheel or lever allows precise control over water flow without requiring external power.

Stainless Steel Body – Durable, corrosion-resistant, and suitable for sanitary applications in food, beverage, pharmaceutical, and water systems.

Hygienic Design – Smooth, crevice-free surfaces reduce contamination risk and support easy cleaning and maintenance.

Versatile Connections – Supports clamp, welded, or threaded ends for easy integration into various pipeline systems.

Reliable Performance – Ensures consistent flow control, durable sealing, and long service life in high-purity water applications

Application

The Stainless Steel Sanitary Rubber Manual Water Diaphragm Valve is used in industries requiring safe and hygienic water handling. Typical applications include beverage production, dairy processing, pharmaceutical water systems, laboratory water distribution, and clean-in-place (CIP) circuits, where reliable, leak-free flow control is essential.