| Availability: | |

|---|---|

| Quantity: | |

JONENG

8421219990

Stainless Steel Sanitary Threaded Manual Ball Tank Bottom Valve

The stainless steel sanitary manual ball tank bottom valve is mainly used for the controlled discharge of fluid at the bottom of the tank body, especially when liquid or slurry is easy to remain at the bottom of the tank, to ensure that each discharge is thorough and residue-free. It uses the design of the spherical valve seat through manual operation to accurately adjust the fluid flow or completely close the fluid channel, avoiding material retention in the valve body. In high-demand hygienic environments such as food, beverages, and pharmaceuticals, it can effectively avoid risks such as contamination and cross-infection, while facilitating cleaning and maintenance to ensure long-term stable and safe operation of the equipment.

remain at the bottom of the tank, to ensure that each discharge is thorough and residue-free. It uses the design of the spherical valve seat through manual operation to accurately adjust the fluid flow or completely close the fluid channel, avoiding material retention in the valve body. In high-demand hygienic environments such as food, beverages, and pharmaceuticals, it can effectively avoid risks such as contamination and cross-infection, while facilitating cleaning and maintenance to ensure long-term stable and safe operation of the equipment.

Working Principles

The working principle of the stainless steel sanitary manual ball tank bottom valve is based on the ball valve seat and manual control. First, when the operator rotates the valve handle, the ball valve core in the valve body begins to rotate, opening or closing the fluid channel. There is a spherical hole in the spherical valve seat, and the fluid can only flow through this hole. When the valve is fully closed, the ball valve core is in close contact with the valve seat to ensure sealing and no fluid leakage. In the open state, the fluid flows out of the tank through the spherical hole for discharge.

The options of the stainless steel sanitary manual ball tank bottom valve include:

Drive mode: manual, pneumatic.

Sealing material: silicone, PTFE, EPDM.

Connection method: clamp, welding, thread.

Valve size: different diameters, suitable for different tanks.

Valve type: normally closed, normally open.

Cleaning function: optional automatic cleaning function.

Discharge port design: straight-through, L-type, T-type.

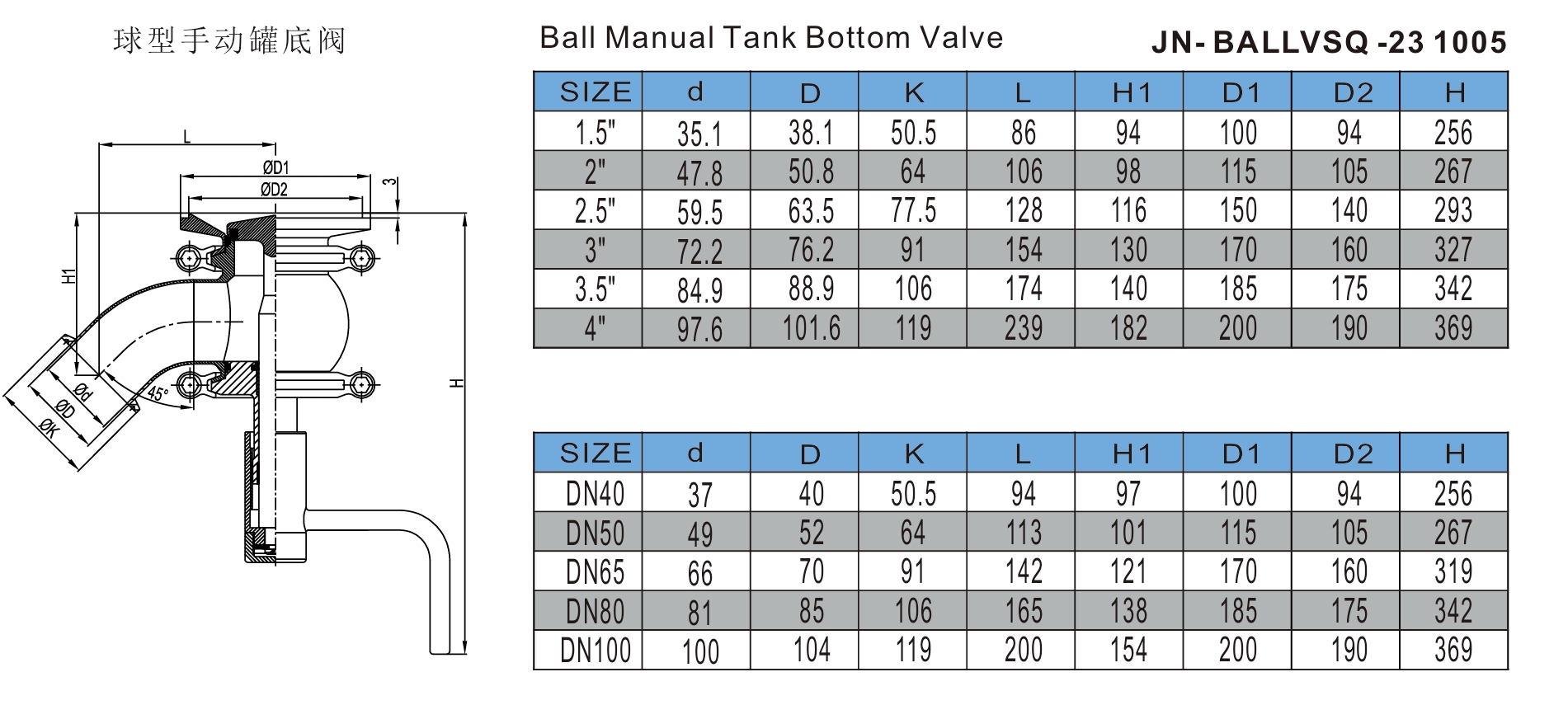

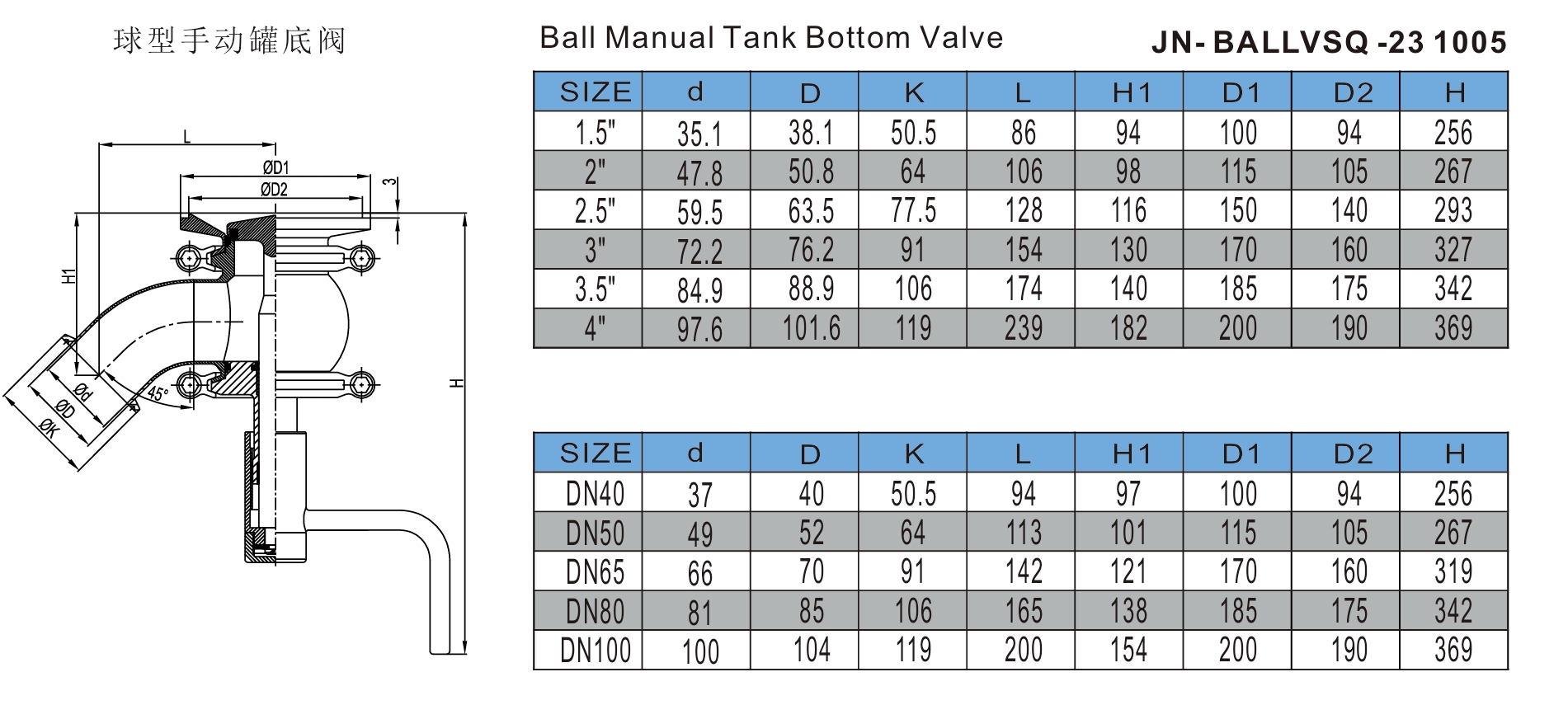

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● The stainless steel sanitary manual ball tank bottom valve is designed with a self-cleaning ball valve core. When the valve is opened, the fluid passes through the movement path of the ball valve core and can take away the dirt and impurities attached to the valve core.

● The stainless steel sanitary manual ball tank bottom valve adopts low-friction sealing technology to make the contact between the seal and the ball valve core smoother, reduce friction loss, and increase the switching life of the valve.

● The ball design of the stainless steel sanitary manual ball tank bottom valve is embedded with an automatic locking device to ensure that the valve can be automatically locked in the closed state during use to prevent accidental opening of the valve due to pressure fluctuations.

● The flow channel inside the stainless steel sanitary manual ball tank bottom valve is optimized to reduce the resistance in the flow of the fluid and ensure that the fluid can pass smoothly without too much interference.

● The stainless steel sanitary manual ball tank bottom valve is equipped with an anti-scaling coating to prevent minerals or other impurities in the liquid from depositing and scaling inside the valve body.

● The stainless steel sanitary manual spherical tank bottom valve is equipped with an automatic pressure balancing device, which can detect the pressure difference on both sides of the valve in real time and automatically adjust the valve sealing pressure to avoid valve failure due to excessive pressure difference.

Application

Stainless steel sanitary manual ball tank bottom valves are widely used in the following industries: Food industry: used for liquid food discharge to ensure pollution-free and hygienic conditions. Beverage industry: used for beverage raw materials or finished product liquid discharge to ensure hygienic safety. Pharmaceutical industry: discharge pharmaceutical liquids to prevent cross contamination and meet GMP standards. Chemical industry: used for chemical discharge to avoid leakage and ensure safe operation. Dairy industry: liquid dairy product discharge to maintain product quality and hygiene requirements. Water treatment industry: used to discharge treated water to ensure that water quality meets standards. Cosmetics industry: discharge liquids in the cosmetics production process to prevent pollution. Biotechnology industry: used for culture liquid discharge to maintain a sterile environment.

Working Principles

The working principle of the stainless steel sanitary manual ball tank bottom valve is based on the ball valve seat and manual control. First, when the operator rotates the valve handle, the ball valve core in the valve body begins to rotate, opening or closing the fluid channel. There is a spherical hole in the spherical valve seat, and the fluid can only flow through this hole. When the valve is fully closed, the ball valve core is in close contact with the valve seat to ensure sealing and no fluid leakage. In the open state, the fluid flows out of the tank through the spherical hole for discharge.

The options of the stainless steel sanitary manual ball tank bottom valve include:

Drive mode: manual, pneumatic.

Sealing material: silicone, PTFE, EPDM.

Connection method: clamp, welding, thread.

Valve size: different diameters, suitable for different tanks.

Valve type: normally closed, normally open.

Cleaning function: optional automatic cleaning function.

Discharge port design: straight-through, L-type, T-type.

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● The stainless steel sanitary manual ball tank bottom valve is designed with a self-cleaning ball valve core. When the valve is opened, the fluid passes through the movement path of the ball valve core and can take away the dirt and impurities attached to the valve core.

● The stainless steel sanitary manual ball tank bottom valve adopts low-friction sealing technology to make the contact between the seal and the ball valve core smoother, reduce friction loss, and increase the switching life of the valve.

● The ball design of the stainless steel sanitary manual ball tank bottom valve is embedded with an automatic locking device to ensure that the valve can be automatically locked in the closed state during use to prevent accidental opening of the valve due to pressure fluctuations.

● The flow channel inside the stainless steel sanitary manual ball tank bottom valve is optimized to reduce the resistance in the flow of the fluid and ensure that the fluid can pass smoothly without too much interference.

● The stainless steel sanitary manual ball tank bottom valve is equipped with an anti-scaling coating to prevent minerals or other impurities in the liquid from depositing and scaling inside the valve body.

● The stainless steel sanitary manual spherical tank bottom valve is equipped with an automatic pressure balancing device, which can detect the pressure difference on both sides of the valve in real time and automatically adjust the valve sealing pressure to avoid valve failure due to excessive pressure difference.

Application

Stainless steel sanitary manual ball tank bottom valves are widely used in the following industries: Food industry: used for liquid food discharge to ensure pollution-free and hygienic conditions. Beverage industry: used for beverage raw materials or finished product liquid discharge to ensure hygienic safety. Pharmaceutical industry: discharge pharmaceutical liquids to prevent cross contamination and meet GMP standards. Chemical industry: used for chemical discharge to avoid leakage and ensure safe operation. Dairy industry: liquid dairy product discharge to maintain product quality and hygiene requirements. Water treatment industry: used to discharge treated water to ensure that water quality meets standards. Cosmetics industry: discharge liquids in the cosmetics production process to prevent pollution. Biotechnology industry: used for culture liquid discharge to maintain a sterile environment.