| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary three-piece clamp is a fastener for pipe connections, consisting of three separate parts to provide fast and reliable connections. Stainless steel sanitary three-piece clamps are widely used in sanitary piping systems in the food, pharmaceutical, dairy and chemical industries, and are usually installed at pipe connections that require rapid disassembly, cleaning or maintenance. It is used to connect different pipe segments, equipment interfaces or fluid shunt points to provide reliable sealing and ensure smooth flow of fluid in the pipe. There are mainly the following types of stainless steel sanitary three-piece clamps: standard type, reducer type, washer type, quick disassembly type, and high-pressure type.

JONENG

8481804090

Stainless Steel Sanitary Three-piece Clamp For Pharmaceutical Preparation

The stainless steel sanitary three-piece clamp is designed to provide a reliable and flexible pipe connection solution in a highly demanding sanitary environment. Compared with traditional clamps, the three-piece clamp is composed of three separate sections (clutch, bolts and washers), providing better sealing performance, ensuring that the pipeline connection is stable, leak-free, and easier to disassemble and replace in high-frequency cleaning and high-pressure fluid delivery processes. At the same time, its removable properties reduce equipment downtime, simplify maintenance, and enable piping systems to remain efficient and continuous, meeting industry strict hygiene standards.

Working Principles

The working principle of stainless steel sanitary three-piece clamp is based on its three parts of structure: clamp, washer and bolts. First, during installation, the two ends of the clamp are aligned with the connecting ports of the pipe or equipment to ensure that the pipes at both ends are in solid contact. The gasket is then placed at the connection to act as a sealing function to prevent fluid leakage. Next, the two ends of the clamp are fixed by bolting and applying pressure to tightly press the pipe to ensure that the connection is firm and there is no leakage. The three-piece clamp design enables quick installation and disassembly of the connection, especially for piping systems that require frequent cleaning and maintenance.

Options for stainless steel sanitary three-piece clamps include:

Size: Different pipe diameters (such as DN25, DN50, etc.).

Sealing materials: silicone, EPDM, PTFE, etc.

Surface treatment: polishing, Ra≤0.8μm, etc.

Pressure level: Suitable for different pressure pipes.

Bolt material: stainless steel, alloy material, etc.

Connection method: optional flange, welding, quick loading and other methods.

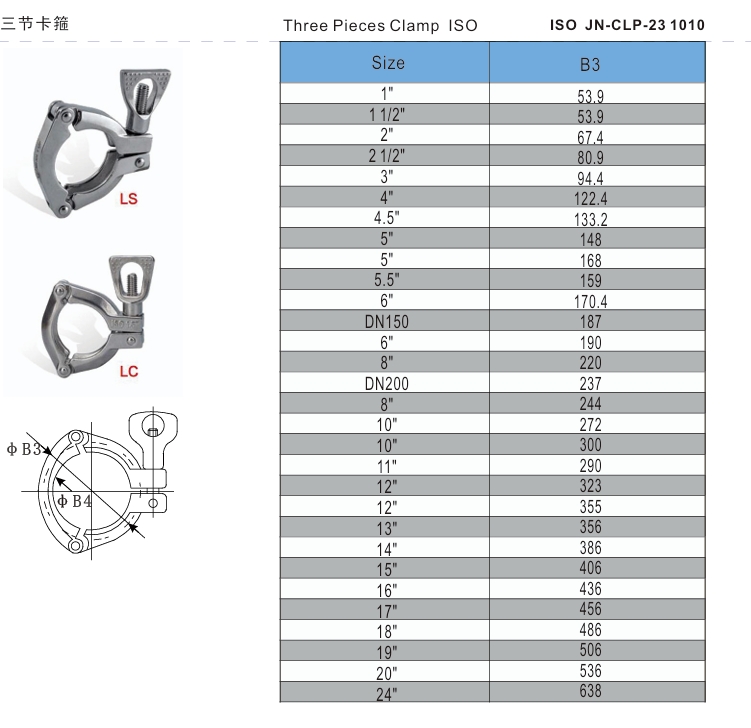

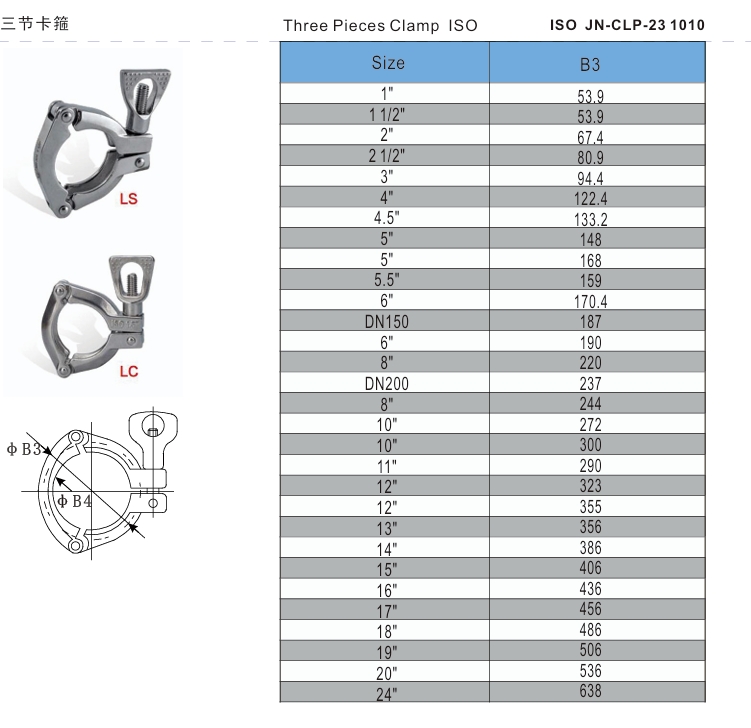

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201,SS201 |

Gasket | Silicone, PTFE, EPDM, viton |

Made from precise casting | |

Features

● The stainless steel sanitary three-piece clamp adopts a self-tightening design. When tightened by bolts, the clamp naturally tightens the pipe connection parts, thereby enhancing the sealing effect.

● The thread locking device on the stainless steel sanitary three-piece clamp can enhance the stability of the connection, and the loosening phenomenon that traditional clamps may occur through locking bolts is effectively avoided.

● The stainless steel sanitary three-piece clamp adopts anti-corrosion surface treatment technology, and adopts special electroplating technology to increase corrosion resistance, which is especially suitable for the transportation of chemicals and corrosive fluids.

● The stainless steel sanitary three-piece clamp design supports a variety of sealing materials (such as EPDM, silicone, PTFE, etc.), and is selected according to different application needs.

● The stainless steel sanitary three-piece clamp has a quick removal function without tools. It can be disassembled by rotating or easily loosening the bolts, which is convenient for daily maintenance and cleaning.

● The internal connection surface of the stainless steel sanitary three-piece clamp is smooth and has no dead corners. The design reduces the opportunity for bacteria and microorganisms to grow, ensuring system hygiene.

Application

Stainless steel sanitary three-piece clamps are widely used in the following industries: Food industry: used for pipeline connections in dairy products, beverages, beer, juice and other production lines. Pharmaceutical industry: Applicable to sterile piping systems to ensure hygiene requirements in the production process of drugs. Biotechnology: used for fluid delivery during fermentation, vaccine production, etc. Cosmetics industry: Connect pipes during cosmetic production to ensure hygiene standards. Chemical industry: Used in chemical conveying systems with high cleanliness requirements. Medical equipment: Liquid delivery and production systems for medical devices.

Working Principles

The working principle of stainless steel sanitary three-piece clamp is based on its three parts of structure: clamp, washer and bolts. First, during installation, the two ends of the clamp are aligned with the connecting ports of the pipe or equipment to ensure that the pipes at both ends are in solid contact. The gasket is then placed at the connection to act as a sealing function to prevent fluid leakage. Next, the two ends of the clamp are fixed by bolting and applying pressure to tightly press the pipe to ensure that the connection is firm and there is no leakage. The three-piece clamp design enables quick installation and disassembly of the connection, especially for piping systems that require frequent cleaning and maintenance.

Options for stainless steel sanitary three-piece clamps include:

Size: Different pipe diameters (such as DN25, DN50, etc.).

Sealing materials: silicone, EPDM, PTFE, etc.

Surface treatment: polishing, Ra≤0.8μm, etc.

Pressure level: Suitable for different pressure pipes.

Bolt material: stainless steel, alloy material, etc.

Connection method: optional flange, welding, quick loading and other methods.

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201,SS201 |

Gasket | Silicone, PTFE, EPDM, viton |

Made from precise casting | |

Features

● The stainless steel sanitary three-piece clamp adopts a self-tightening design. When tightened by bolts, the clamp naturally tightens the pipe connection parts, thereby enhancing the sealing effect.

● The thread locking device on the stainless steel sanitary three-piece clamp can enhance the stability of the connection, and the loosening phenomenon that traditional clamps may occur through locking bolts is effectively avoided.

● The stainless steel sanitary three-piece clamp adopts anti-corrosion surface treatment technology, and adopts special electroplating technology to increase corrosion resistance, which is especially suitable for the transportation of chemicals and corrosive fluids.

● The stainless steel sanitary three-piece clamp design supports a variety of sealing materials (such as EPDM, silicone, PTFE, etc.), and is selected according to different application needs.

● The stainless steel sanitary three-piece clamp has a quick removal function without tools. It can be disassembled by rotating or easily loosening the bolts, which is convenient for daily maintenance and cleaning.

● The internal connection surface of the stainless steel sanitary three-piece clamp is smooth and has no dead corners. The design reduces the opportunity for bacteria and microorganisms to grow, ensuring system hygiene.

Application

Stainless steel sanitary three-piece clamps are widely used in the following industries: Food industry: used for pipeline connections in dairy products, beverages, beer, juice and other production lines. Pharmaceutical industry: Applicable to sterile piping systems to ensure hygiene requirements in the production process of drugs. Biotechnology: used for fluid delivery during fermentation, vaccine production, etc. Cosmetics industry: Connect pipes during cosmetic production to ensure hygiene standards. Chemical industry: Used in chemical conveying systems with high cleanliness requirements. Medical equipment: Liquid delivery and production systems for medical devices.