| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary hexagonal pipe bracket is a connection component used to support the pipeline system. It is mainly used for pipeline support and fixation to ensure that the pipeline system remains stable during transportation, storage and use. The stainless steel sanitary hexagonal pipe bracket is mainly used in the pipeline systems of the food, beverage, pharmaceutical, chemical and other industries, especially those production lines with high hygiene requirements. It is usually installed at the supporting point of the pipeline to support and fix the horizontal or vertical pipeline to prevent the pipeline from being displaced or damaged due to external force or vibration. There are mainly the following types of stainless steel sanitary hexagonal pipe brackets: fixed hexagonal pipe bracket, adjustable hexagonal pipe bracket, hoisting hexagonal pipe bracket, and angle hexagonal pipe bracket.

JONENG

8481804090

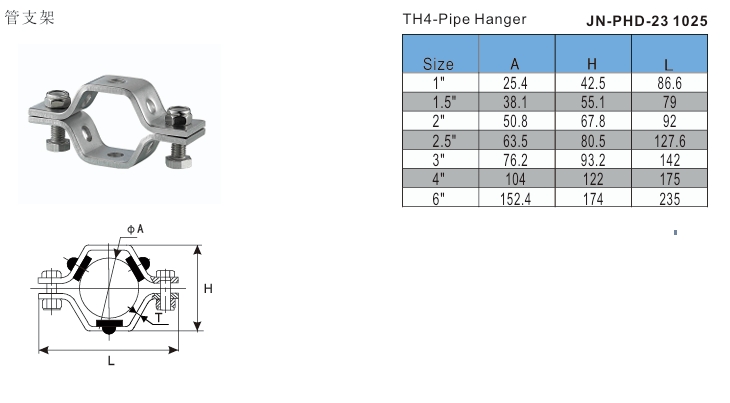

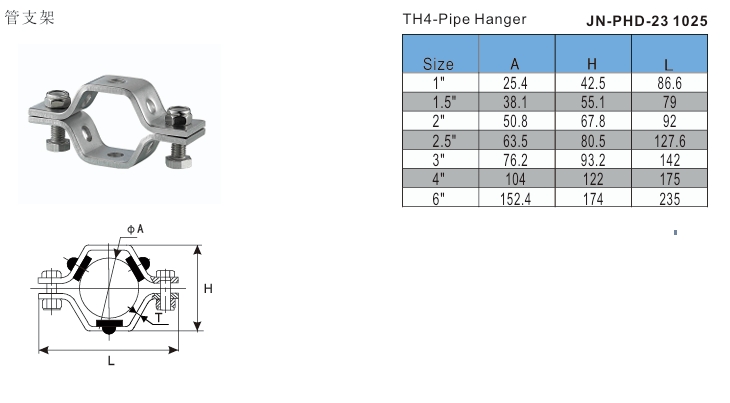

Stainless Steel Sanitary Bolt-Fixed Hexagonal Pipe Bracket

The stainless steel sanitary hexagonal pipe bracket is designed to provide a stable support for the pipeline system. Its hexagonal design not only enhances the strength and stability of the bracket, but also enables it to withstand greater pipeline loads, avoiding displacement or damage of the pipeline due to external force or vibration. The bracket is made of stainless steel with good corrosion resistance and high temperature resistance, ensuring that it will not rust or corrode during long-term use, meet hygiene requirements, and is easy to clean and maintain. In addition, the bracket design takes into account the need for quick installation and removal of the pipeline, reducing the time and cost of installation and maintenance.

Working Principles

The working principle of the stainless steel sanitary hexagonal pipe bracket is based on the stable support and fixing it provides. During installation, the bracket is connected to the pipeline by bolts or welding, and fixed to the ground, wall or supporting structure. The hexagonal design of the bracket enhances its strength and can evenly distribute the load of the pipeline. By adjusting the height or angle of the bracket (for adjustable brackets), the correct position of the pipeline in the system can be ensured. The design of the bracket also takes into account the seismic and vibration resistance, which can effectively prevent the pipeline from being displaced or damaged by external forces or vibration. After installation, the bracket provides stable support throughout the pipeline system, ensuring that the pipeline is always at the correct angle and position during operation, thereby ensuring the smooth flow of fluids and the long-term reliability of the system.

The options of the stainless steel sanitary hexagonal pipe bracket include:

Size: Different bracket sizes can be selected according to the diameter of the pipeline.

Type: Such as fixed type, adjustable type, hoisting type, angle type, etc.

Material: Stainless steel 304 or 316L, adapted to different environmental requirements.

Surface treatment: such as polishing, spraying, pickling, etc. to improve corrosion resistance.

Installation method: bolt fixing, welding or clamping, etc.

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The main body of the stainless steel sanitary hexagonal tube bracket adopts a hexagonal honeycomb hollow design. Under the premise of ensuring the load-bearing strength, the weight is 40% lighter than the traditional solid bracket.

● The surface of the stainless steel sanitary hexagonal tube bracket is treated with nano-silicon coating to form a hydrophobic and oleophobic film layer to prevent fingerprints or oil stains during operation and keep the appearance clean.

● The stainless steel sanitary hexagonal tube bracket has built-in elastic gaskets and fine-tuning bolts at the connection, allowing ±5° angle adaptive adjustment to compensate for slight deviations during pipeline installation and avoid stress concentration caused by hard connection.

● The stainless steel sanitary hexagonal tube bracket adopts specially smelted 316L stainless steel, doped with trace copper-silver alloy, which gives the material natural antibacterial properties and inhibits the growth of Escherichia coli and Staphylococcus aureus.

● After forming, the stainless steel sanitary hexagonal tube bracket is deep-cold treated with -196℃ liquid nitrogen to eliminate internal residual stress, improve the ability to resist intergranular corrosion, and extend the life by more than 50% in strong acid, strong alkali or high salt environment.

● The contact surface between the stainless steel sanitary hexagonal pipe bracket and the pipeline is embedded with a strong magnet, which automatically adsorbs and positions during installation without manual alignment.

Application

Stainless steel sanitary hexagonal pipe brackets are widely used in the following industries: Food processing industry: used to support pipelines in food production lines to ensure high hygiene standards and prevent pollution. Pharmaceutical industry: support pipelines in pharmaceutical production and distribution systems to meet strict hygiene and corrosion resistance requirements. Beverage industry: support beverage production line pipelines to ensure hygiene and adapt to high requirements for liquid transportation. Chemical industry: used for supporting chemical liquid or gas pipelines, especially in corrosive environments. Dairy processing industry: ensure the stability and hygiene of the pipeline system during dairy processing to prevent pollution.

Working Principles

The working principle of the stainless steel sanitary hexagonal pipe bracket is based on the stable support and fixing it provides. During installation, the bracket is connected to the pipeline by bolts or welding, and fixed to the ground, wall or supporting structure. The hexagonal design of the bracket enhances its strength and can evenly distribute the load of the pipeline. By adjusting the height or angle of the bracket (for adjustable brackets), the correct position of the pipeline in the system can be ensured. The design of the bracket also takes into account the seismic and vibration resistance, which can effectively prevent the pipeline from being displaced or damaged by external forces or vibration. After installation, the bracket provides stable support throughout the pipeline system, ensuring that the pipeline is always at the correct angle and position during operation, thereby ensuring the smooth flow of fluids and the long-term reliability of the system.

The options of the stainless steel sanitary hexagonal pipe bracket include:

Size: Different bracket sizes can be selected according to the diameter of the pipeline.

Type: Such as fixed type, adjustable type, hoisting type, angle type, etc.

Material: Stainless steel 304 or 316L, adapted to different environmental requirements.

Surface treatment: such as polishing, spraying, pickling, etc. to improve corrosion resistance.

Installation method: bolt fixing, welding or clamping, etc.

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The main body of the stainless steel sanitary hexagonal tube bracket adopts a hexagonal honeycomb hollow design. Under the premise of ensuring the load-bearing strength, the weight is 40% lighter than the traditional solid bracket.

● The surface of the stainless steel sanitary hexagonal tube bracket is treated with nano-silicon coating to form a hydrophobic and oleophobic film layer to prevent fingerprints or oil stains during operation and keep the appearance clean.

● The stainless steel sanitary hexagonal tube bracket has built-in elastic gaskets and fine-tuning bolts at the connection, allowing ±5° angle adaptive adjustment to compensate for slight deviations during pipeline installation and avoid stress concentration caused by hard connection.

● The stainless steel sanitary hexagonal tube bracket adopts specially smelted 316L stainless steel, doped with trace copper-silver alloy, which gives the material natural antibacterial properties and inhibits the growth of Escherichia coli and Staphylococcus aureus.

● After forming, the stainless steel sanitary hexagonal tube bracket is deep-cold treated with -196℃ liquid nitrogen to eliminate internal residual stress, improve the ability to resist intergranular corrosion, and extend the life by more than 50% in strong acid, strong alkali or high salt environment.

● The contact surface between the stainless steel sanitary hexagonal pipe bracket and the pipeline is embedded with a strong magnet, which automatically adsorbs and positions during installation without manual alignment.

Application

Stainless steel sanitary hexagonal pipe brackets are widely used in the following industries: Food processing industry: used to support pipelines in food production lines to ensure high hygiene standards and prevent pollution. Pharmaceutical industry: support pipelines in pharmaceutical production and distribution systems to meet strict hygiene and corrosion resistance requirements. Beverage industry: support beverage production line pipelines to ensure hygiene and adapt to high requirements for liquid transportation. Chemical industry: used for supporting chemical liquid or gas pipelines, especially in corrosive environments. Dairy processing industry: ensure the stability and hygiene of the pipeline system during dairy processing to prevent pollution.