| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary quick-install tubular filter is a filtering device widely used in the food, beverage, medicine, cosmetics and chemical industries. It is made of stainless steel as the main material, has a sanitary design, and is connected to the pipeline system by quick installation to ensure the cleanliness of the production process and the quality of the product.

The stainless steel sanitary quick-install tubular filter is usually installed at the inlet or key process node of the pipeline to remove particulate impurities in the liquid or gas, protect downstream equipment and ensure the cleanliness of the fluid.

The stainless steel sanitary quick-install tubular filter is mainly divided into the following types according to the structure and purpose: straight-through filter, Y-type filter, T-type filter, bag filter, and cartridge filter.

JONENG

8421219990

Stainless Steel Sanitary Quick-install Tube Filter Housing Cartridge

The stainless steel sanitary quick-install tubular filter is designed to remove particulate impurities in liquid or gas, ensure the cleanliness of the fluid, protect downstream equipment, and improve process efficiency and product quality. Its design adopts quick installation connection for easy disassembly and cleaning, which meets the strict requirements of food, beverage, medicine and other industries for hygiene, safety and high-efficiency filtration, prevents secondary pollution, and ensures the stability of the production process and compliance with relevant regulations.

Working Principles

The working principle of the stainless steel sanitary quick-install tubular filter is to intercept particulate impurities in the fluid through the filter element so that the clean fluid is discharged from the outlet. Impurities are concentrated in the filter element. Clean or replace the filter element regularly to ensure filtration efficiency and system hygiene. It is suitable for scenarios with high cleanliness requirements. The use of stainless steel sanitary quick-install tubular filters meets sanitary design standards, avoids secondary pollution, and ensures product quality and safety. It also has the advantages of easy disassembly and cleaning, strong corrosion resistance, and is suitable for high-demand industries such as food, beverages, and medicine to ensure stable and efficient production processes.

The options for stainless steel sanitary quick-install tubular filters include:

1. Material: 304 or 316L stainless steel.

2. Filter element: filter screen, filter bag, folded filter element.

3. Interface: quick installation, thread, welding interface.

4. Structure: straight-through, Y-type, T-type.

5. Seal: silicone, EPDM, PTFE.

6. Specifications: different pipe diameters and flow options.

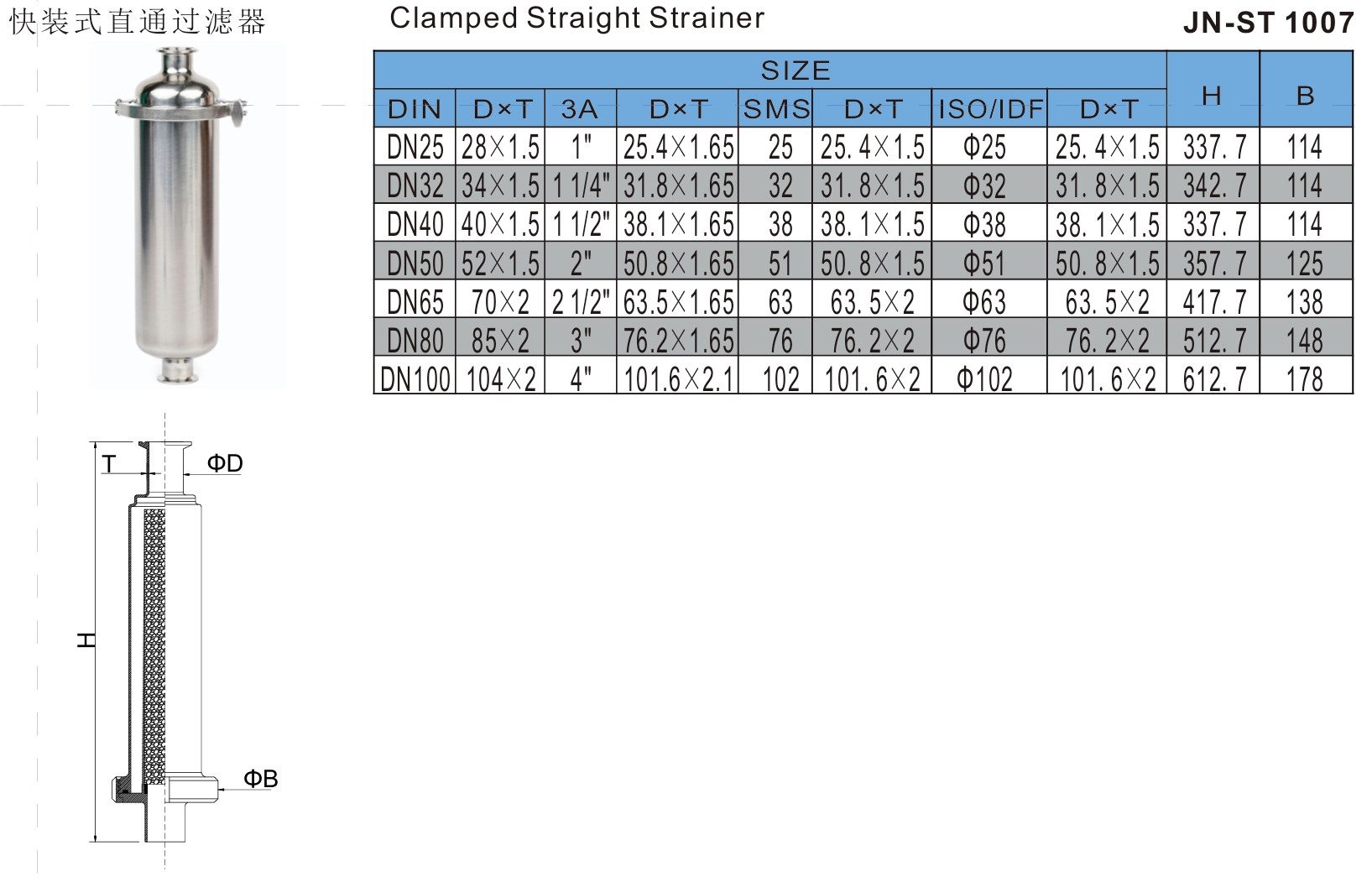

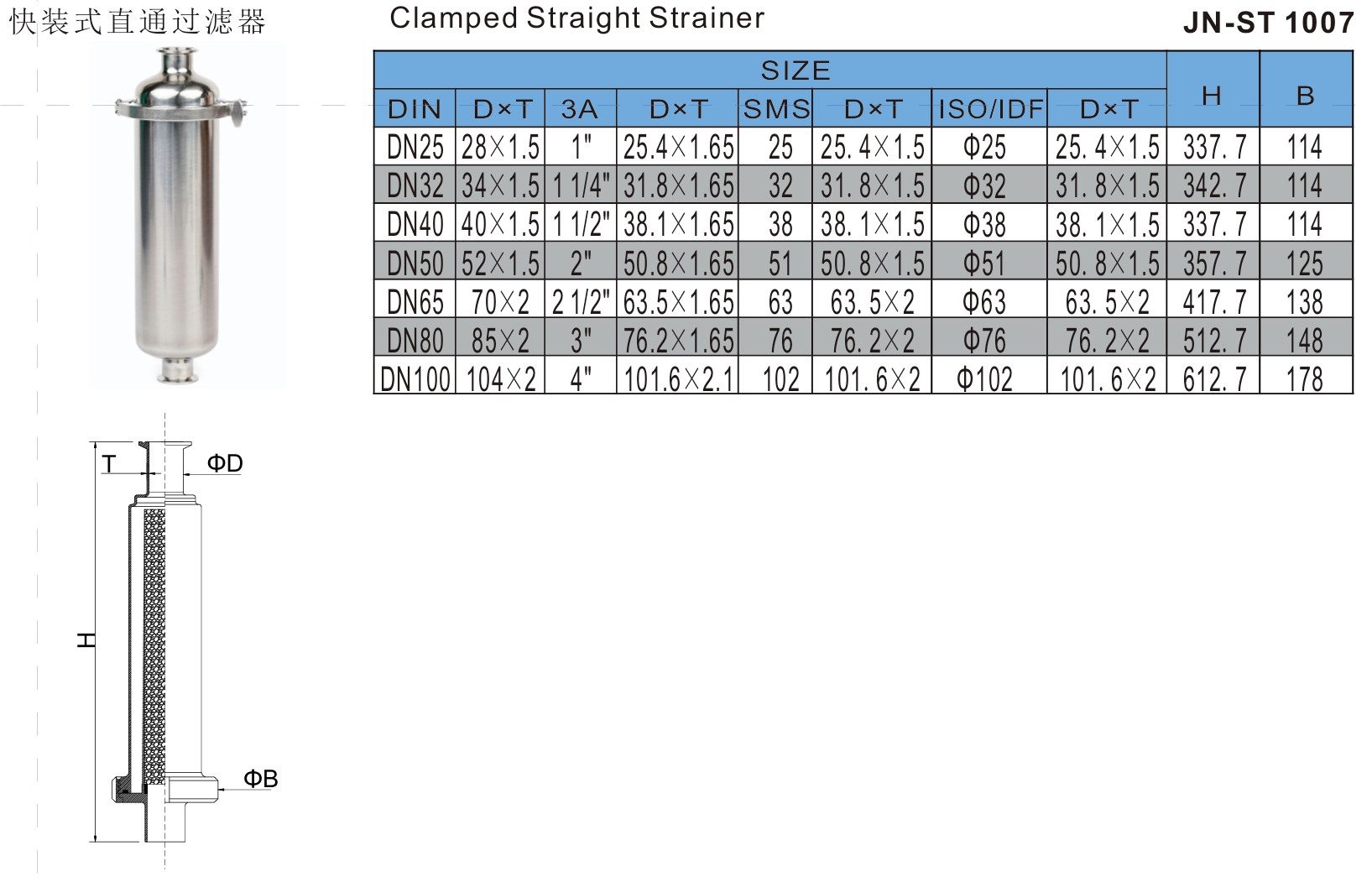

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary quick-install tubular filter adopts quick-install clamps or quick-install threaded interfaces, which is convenient for disassembly, cleaning and replacement of filter elements, and improves maintenance efficiency.

● The stainless steel sanitary quick-install tubular filter is equipped with filter elements of different precisions, and the filtration precision can reach 0.2μm, which meets different process requirements.

● The inner and outer surfaces of the stainless steel sanitary quick-install tubular filter are finely polished, smooth and without dead corners, easy to clean and disinfect, and meet strict hygiene requirements.

● The stainless steel sanitary quick-install tubular filter adopts a modular structure, which is convenient for adjusting the filter configuration according to actual needs and has high flexibility.

● The design of the stainless steel sanitary quick-install tubular filter ensures that the fluid produces minimal pressure loss during the passage process, improving system efficiency.

● The stainless steel sanitary quick-install tubular filter has a compact structure and small footprint, which is suitable for a variety of installation environments and is convenient for industrial production applications.

Application

Stainless steel sanitary quick-install tubular filters are widely used in the following fields: Food industry: Ensure the cleanliness of the product, prevent impurities from entering, and maintain product quality. Beverage industry: Filter impurities in beverages to ensure the hygiene and taste of beverages. Pharmaceutical industry: Ensure sterility and high quality, in line with GMP requirements. Cosmetics industry: Ensure product safety and stability. Chemical industry: Protect equipment and ensure smooth production process. Water treatment industry: Ensure that water quality meets high standards.

Working Principles

The working principle of the stainless steel sanitary quick-install tubular filter is to intercept particulate impurities in the fluid through the filter element so that the clean fluid is discharged from the outlet. Impurities are concentrated in the filter element. Clean or replace the filter element regularly to ensure filtration efficiency and system hygiene. It is suitable for scenarios with high cleanliness requirements. The use of stainless steel sanitary quick-install tubular filters meets sanitary design standards, avoids secondary pollution, and ensures product quality and safety. It also has the advantages of easy disassembly and cleaning, strong corrosion resistance, and is suitable for high-demand industries such as food, beverages, and medicine to ensure stable and efficient production processes.

The options for stainless steel sanitary quick-install tubular filters include:

1. Material: 304 or 316L stainless steel.

2. Filter element: filter screen, filter bag, folded filter element.

3. Interface: quick installation, thread, welding interface.

4. Structure: straight-through, Y-type, T-type.

5. Seal: silicone, EPDM, PTFE.

6. Specifications: different pipe diameters and flow options.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary quick-install tubular filter adopts quick-install clamps or quick-install threaded interfaces, which is convenient for disassembly, cleaning and replacement of filter elements, and improves maintenance efficiency.

● The stainless steel sanitary quick-install tubular filter is equipped with filter elements of different precisions, and the filtration precision can reach 0.2μm, which meets different process requirements.

● The inner and outer surfaces of the stainless steel sanitary quick-install tubular filter are finely polished, smooth and without dead corners, easy to clean and disinfect, and meet strict hygiene requirements.

● The stainless steel sanitary quick-install tubular filter adopts a modular structure, which is convenient for adjusting the filter configuration according to actual needs and has high flexibility.

● The design of the stainless steel sanitary quick-install tubular filter ensures that the fluid produces minimal pressure loss during the passage process, improving system efficiency.

● The stainless steel sanitary quick-install tubular filter has a compact structure and small footprint, which is suitable for a variety of installation environments and is convenient for industrial production applications.

Application

Stainless steel sanitary quick-install tubular filters are widely used in the following fields: Food industry: Ensure the cleanliness of the product, prevent impurities from entering, and maintain product quality. Beverage industry: Filter impurities in beverages to ensure the hygiene and taste of beverages. Pharmaceutical industry: Ensure sterility and high quality, in line with GMP requirements. Cosmetics industry: Ensure product safety and stability. Chemical industry: Protect equipment and ensure smooth production process. Water treatment industry: Ensure that water quality meets high standards.