| Availability: | |

|---|---|

| Quantity: | |

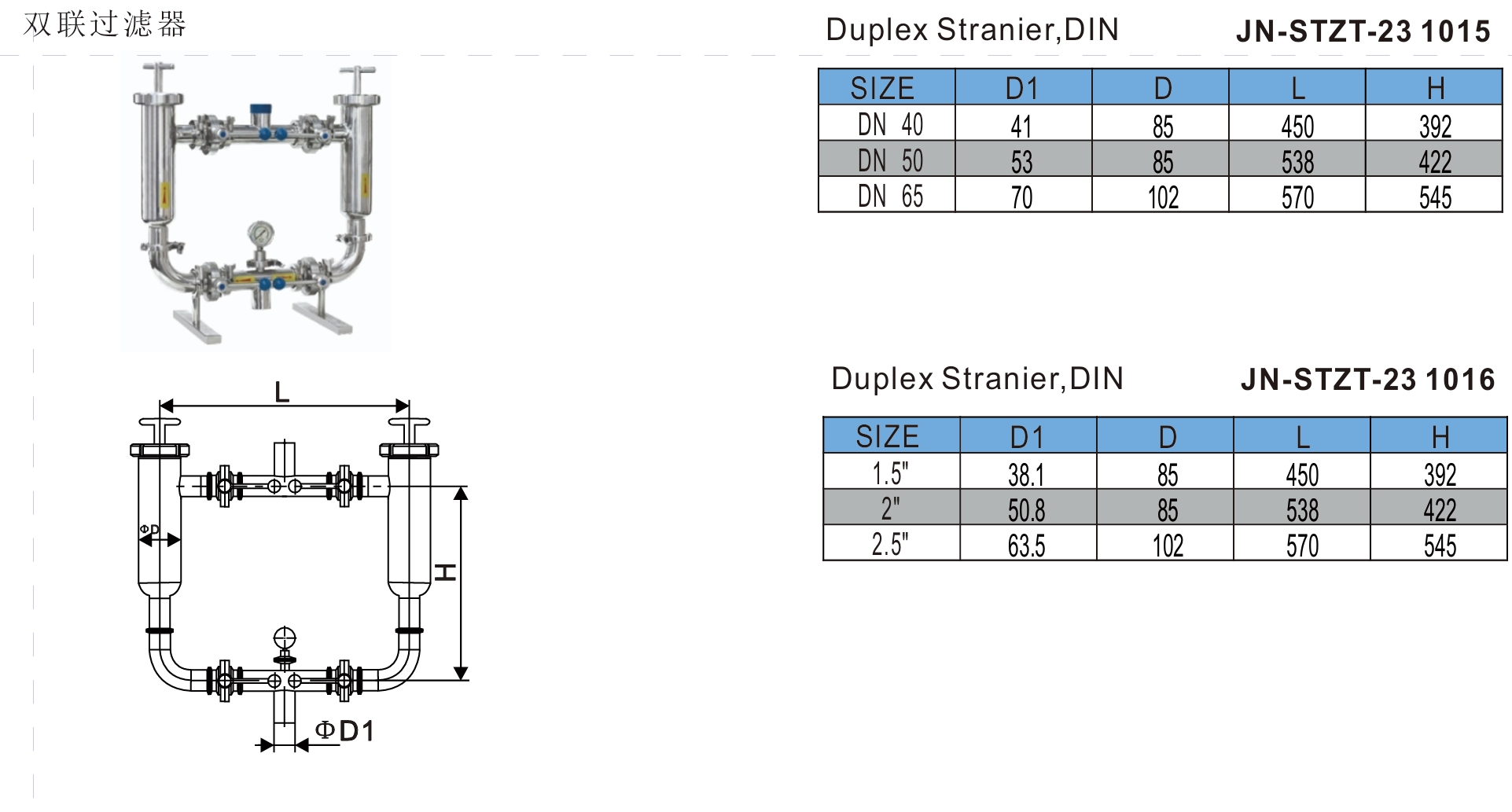

The stainless steel sanitary duplex filter is a highly efficient filtering equipment that can be used in fine chemical production to ensure the stability of chemical reactions in a low-pollution environment, or to filter gases in a high-cleanliness environment to prevent foreign particles from interfering with the production process. The stainless steel sanitary duplex filter is usually used in the pipeline system of the food, beverage, pharmaceutical and other industries, and is installed at the water inlet or outlet of the pipeline. It is used to filter impurities in the liquid, ensure product quality, and prevent pollutants from entering the production or storage process. The common types of stainless steel sanitary duplex filters are mainly the following: Y-type duplex filter, T-type duplex filter, basket duplex filter, precision duplex filter.

JONENG

8421219990

Stainless Steel Sanitary TriClamp Duplex Micron Filter Housing

The stainless steel sanitary duplex filter is mainly used for liquid filtration in the pipeline system of the food, beverage, pharmaceutical and other industries. Its design purpose is to improve the filtration efficiency through the duplex structure and ensure that the liquid is not contaminated by impurities during the processing process. The duplex filter is usually equipped with two filter units, which can be used in turn to ensure that when one unit needs to be cleaned or maintained, the other unit continues to operate to avoid interruption of the production process. This design not only improves the reliability of the system, but also reduces maintenance costs. It is suitable for occasions that require high hygiene standards and continuous production.

Working Principles

The working principle of the stainless steel sanitary duplex filter is based on the design of alternating use of dual filter elements. When the system is working, one filter element is in the filtering state, while the other is in the standby state. When the filter element needs to be cleaned or replaced, the system automatically switches to the standby filter element to ensure the continuous operation of the filtration system. The double-link design inside the filter makes the cleaning, maintenance and replacement process not affect the production process, and is widely used in industrial environments that require high cleanliness, such as food, beverage and pharmaceutical fields. Each filter element has an independent inlet and outlet to ensure that the fluid flow is not disturbed.

The options of the stainless steel sanitary duplex filter include:

Filter mesh aperture: choose different apertures according to the filtration accuracy.

Connection method: such as welding, threading, quick installation, etc.

Cleaning method: manual cleaning or automatic backwashing.

Material: 304, 316L stainless steel, etc.

Drainage method: manual or automatic drainage function.

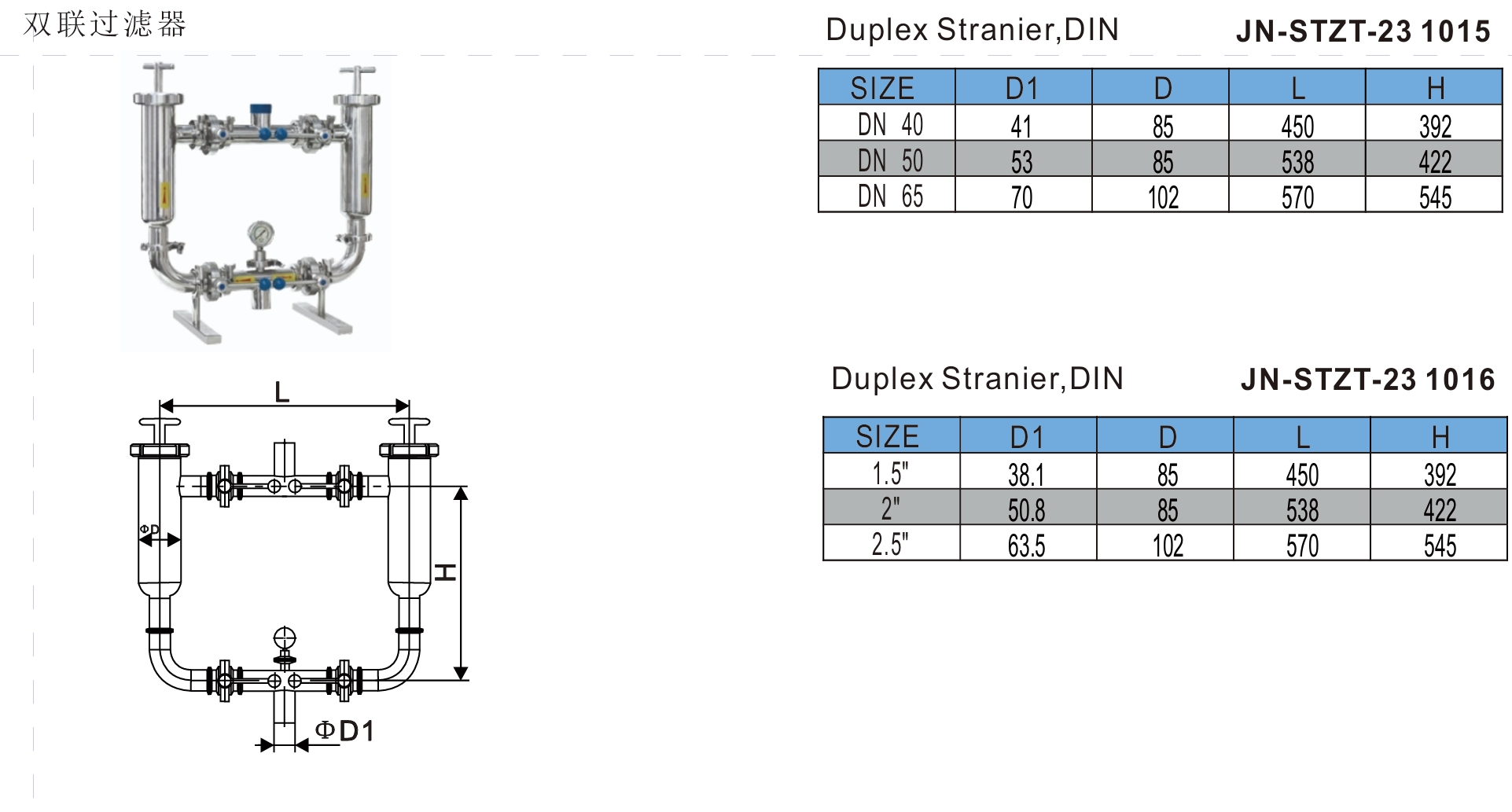

Specification Chart

Material | SS304, SS316L |

Size | 1”-4” |

Inner surface finish | Ra0.5 |

External surface finish | Ra 0.8 |

Standard | SMS, 3A, BPE, ISO |

Seals | EPDM, PTFE, Silicone |

Max pressure | 10 bar |

Max temperature | -10℃ to 120℃ |

| End connection | Threaded, welded, clamped |

| Screen | 30-300 meshes |

| Screen hole | 0.5mm-2mm |

Features

● The stainless steel sanitary duplex filter adopts a double sealing structure to effectively prevent liquid leakage, ensure the safety and reliability of the pipeline system, and adapt to high-pressure environments.

● The stainless steel sanitary duplex filter is equipped with an automatic backwashing system, which can regularly clean the filter screen, reduce the frequency of manual maintenance, and extend the service life.

● The inner wall of the stainless steel sanitary duplex filter is mirror-polished to reduce the resistance in the flow of liquid and effectively prevent dirt deposition to ensure long-term stable operation.

● The stainless steel sanitary duplex filter adopts a special filter screen design and flow channel structure to optimize the flow path of the fluid, reduce flow resistance, and improve the overall efficiency of the system.

● The stainless steel sanitary duplex filter uses a snap-on connection design, which can be quickly disassembled, reducing the workload during maintenance and saving equipment downtime.

● The stainless steel sanitary duplex filter integrates a temperature control system, which can automatically adjust the filtration rate according to the liquid temperature to ensure the filtration efficiency under different working conditions.

Application

Stainless steel sanitary duplex filters are used in the following industries: Food industry: filter liquids, keep products clean, and prevent impurity contamination. Pharmaceutical industry: ensure the purity of fluids in the drug production process to avoid cross contamination. Beverage industry: filter beverage raw materials to ensure product quality and safety. Cosmetics industry: filter liquids in the production process to ensure that the product is free of impurities. Water treatment industry: remove solid impurities in water and improve water quality. Biotechnology: Filter culture and experimental fluids to ensure contamination-free.

Working Principles

The working principle of the stainless steel sanitary duplex filter is based on the design of alternating use of dual filter elements. When the system is working, one filter element is in the filtering state, while the other is in the standby state. When the filter element needs to be cleaned or replaced, the system automatically switches to the standby filter element to ensure the continuous operation of the filtration system. The double-link design inside the filter makes the cleaning, maintenance and replacement process not affect the production process, and is widely used in industrial environments that require high cleanliness, such as food, beverage and pharmaceutical fields. Each filter element has an independent inlet and outlet to ensure that the fluid flow is not disturbed.

The options of the stainless steel sanitary duplex filter include:

Filter mesh aperture: choose different apertures according to the filtration accuracy.

Connection method: such as welding, threading, quick installation, etc.

Cleaning method: manual cleaning or automatic backwashing.

Material: 304, 316L stainless steel, etc.

Drainage method: manual or automatic drainage function.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary duplex filter adopts a double sealing structure to effectively prevent liquid leakage, ensure the safety and reliability of the pipeline system, and adapt to high-pressure environments.

● The stainless steel sanitary duplex filter is equipped with an automatic backwashing system, which can regularly clean the filter screen, reduce the frequency of manual maintenance, and extend the service life.

● The inner wall of the stainless steel sanitary duplex filter is mirror-polished to reduce the resistance in the flow of liquid and effectively prevent dirt deposition to ensure long-term stable operation.

● The stainless steel sanitary duplex filter adopts a special filter screen design and flow channel structure to optimize the flow path of the fluid, reduce flow resistance, and improve the overall efficiency of the system.

● The stainless steel sanitary duplex filter uses a snap-on connection design, which can be quickly disassembled, reducing the workload during maintenance and saving equipment downtime.

● The stainless steel sanitary duplex filter integrates a temperature control system, which can automatically adjust the filtration rate according to the liquid temperature to ensure the filtration efficiency under different working conditions.

Application

Stainless steel sanitary duplex filters are used in the following industries: Food industry: filter liquids, keep products clean, and prevent impurity contamination. Pharmaceutical industry: ensure the purity of fluids in the drug production process to avoid cross contamination. Beverage industry: filter beverage raw materials to ensure product quality and safety. Cosmetics industry: filter liquids in the production process to ensure that the product is free of impurities. Water treatment industry: remove solid impurities in water and improve water quality. Biotechnology: Filter culture and experimental fluids to ensure contamination-free.