| Availability: | |

|---|---|

| Quantity: | |

A stainless steel double filter is a filtration system that uses two filter elements, usually installed in a pipe, to remove contaminants from the liquid. It consists of two parallel filter housings, usually made of durable stainless steel, that allow continuous operation. When one filter needs cleaning or replacement, traffic is diverted to the other filter, ensuring uninterrupted service.

JONENG

8421219990

Stainless Steel Sanitary TriClamp Single Catridge Duplex Bag Filter

The stainless steel double filter is a filtration system consisting of two interconnected filtration units that enables continuous filtration without system downtime. It plays a vital role in protecting downstream equipment such as pumps, valves and other process components, preventing solid particles from entering and causing damage or disruption.

Working Principles

The stainless steel double filter utilizes two parallel filter units to provide continuous filtration. When fluid enters the system, it passes through one of the filters, trapping impurities and contaminants while the second filter remains in standby mode. If the first filter is blocked or needs maintenance, the water flow is automatically redirected to the second filter, ensuring uninterrupted filtration. After cleaning or replacing the first filter, the first filter is brought back online and the cycle continues.

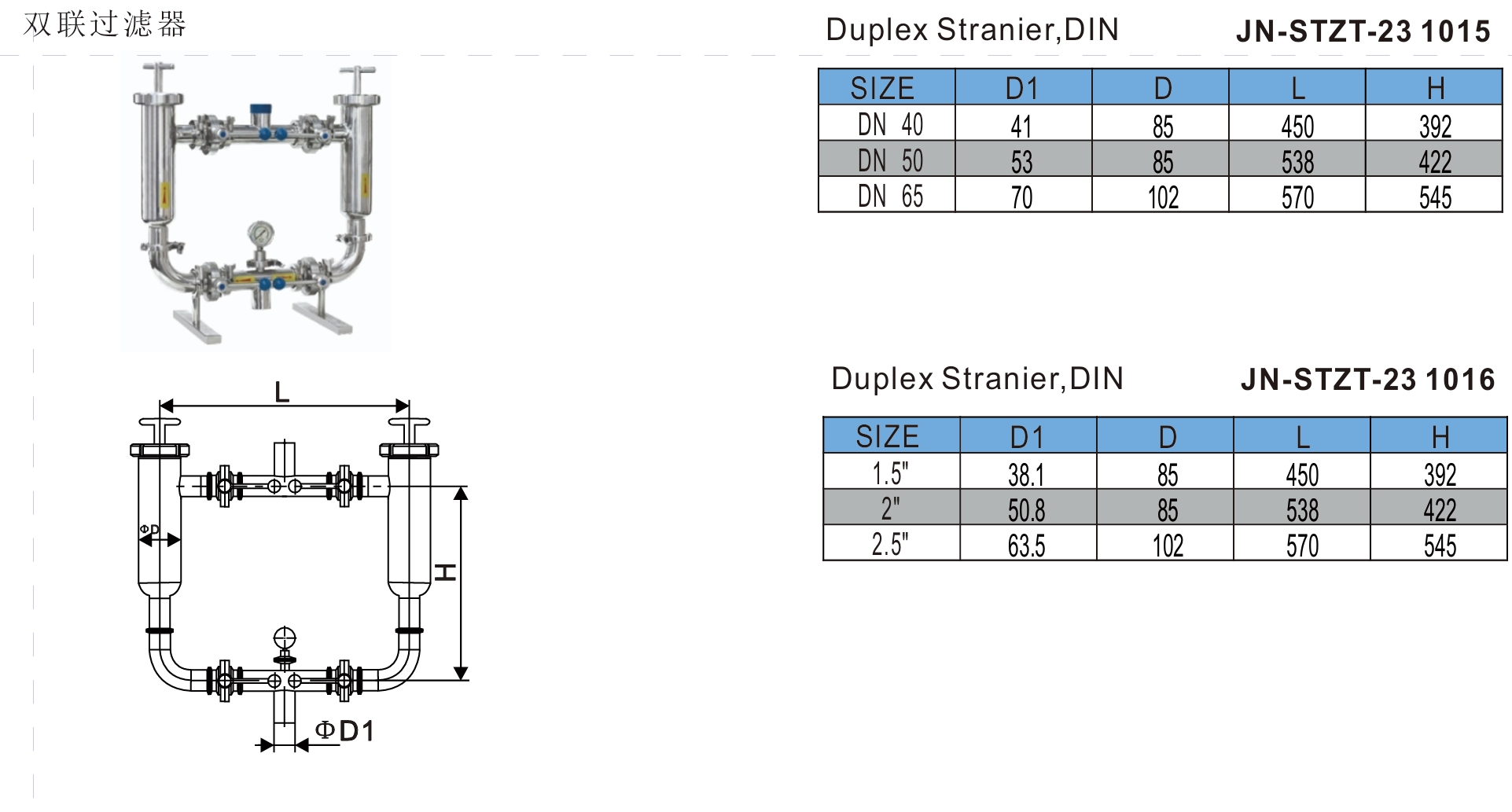

Stainless Steel Duplex Filter Specification Chart

Material | SS304, SS316L |

Size | 1”-4” |

Inner surface finish | Ra0.5 |

External surface finish | Ra 0.8 |

Standard | SMS, 3A, BPE, ISO |

Seals | EPDM, PTFE, Silicone |

Max pressure | 10 bar |

Max temperature | -10℃ to 120℃ |

| End connection | Threaded, welded, clamped |

| Screen | 30-300 meshes |

| Screen hole | 0.5mm-2mm |

Features

● Durability: Made of high-quality stainless steel.

● Continuous operation: The dual filter design allows for uninterrupted filtration.

● High filtration efficiency: Captures fine particles, contaminants, and impurities in liquids and gases.

● Easy maintenance: The filter can be cleaned or replaced without interrupting system flow.

● High pressure and temperature resistance: Suitable for high pressure and high temperature environments.

● Versatility: Suitable for a variety of industries such as chemical, oil and gas, water treatment, and food processing.

● Compact design: Often designed to fit into limited spaces.

Application

Stainless steel duplex filters are widely used in industries that require efficient and continuous filtration, such as the oil and gas industry, chemical industry, food and beverage industry, pharmaceutical industry, water treatment, power plants, HVAC systems and marine applications, ensuring a reliable and uninterrupted filtration process.

Working Principles

The stainless steel double filter utilizes two parallel filter units to provide continuous filtration. When fluid enters the system, it passes through one of the filters, trapping impurities and contaminants while the second filter remains in standby mode. If the first filter is blocked or needs maintenance, the water flow is automatically redirected to the second filter, ensuring uninterrupted filtration. After cleaning or replacing the first filter, the first filter is brought back online and the cycle continues.

Specification

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● Durability: Made of high-quality stainless steel.

● Continuous operation: The dual filter design allows for uninterrupted filtration.

● High filtration efficiency: Captures fine particles, contaminants, and impurities in liquids and gases.

● Easy maintenance: The filter can be cleaned or replaced without interrupting system flow.

●High pressure and temperature resistance: Suitable for high pressure and high temperature environments.

● Versatility: Suitable for a variety of industries such as chemical, oil and gas, water treatment, and food processing.

●Compact design: Often designed to fit into limited spaces.

Application

Stainless steel duplex filters are widely used in industries that require efficient and continuous filtration, such as the oil and gas industry, chemical industry, food and beverage industry, pharmaceutical industry, water treatment, power plants, HVAC systems and marine applications, ensuring a reliable and uninterrupted filtration process.