| Availability: | |

|---|---|

| Quantity: | |

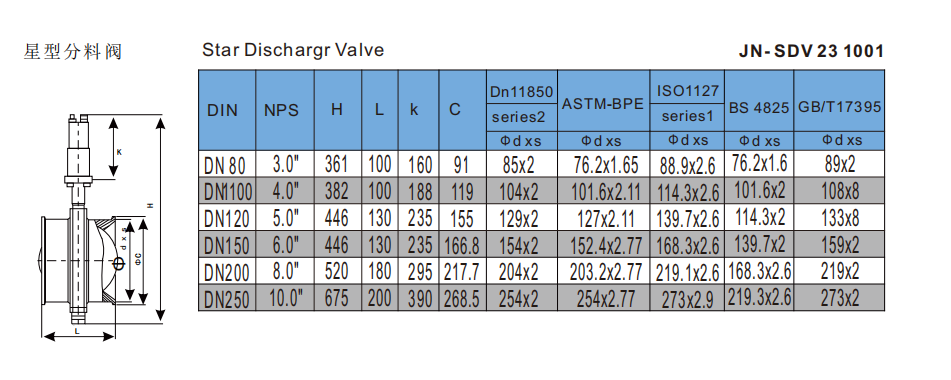

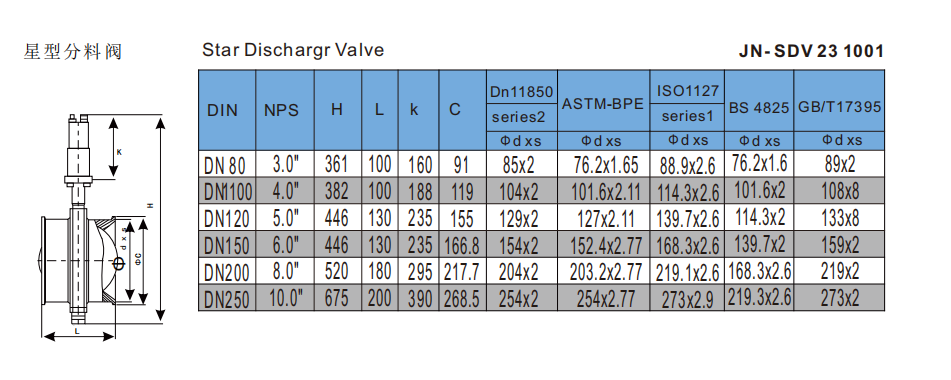

JN- SDV 23 1001

JONENG

8481804090

Stainless Steel Sanitary Triclamp Pneumatic Rotary Split Butterfly Valve

The stainless steel sanitary star-shaped distributor valve is designed to achieve efficient and accurate material distribution in an environment with high hygienic standards. Its unique star-shaped structure can handle multiple fluid paths in one device at the same time, ensuring that the distribution of different materials does not cross-contaminate. It is particularly suitable for handling materials with high viscosity and uneven flow, and can maintain stable and uniform flow distribution on complex production lines. The design also takes into account easy cleaning and low maintenance, making it perform well in demanding food, beverage, pharmaceutical and other industries.

Working Principles

The working principle of the stainless steel sanitary star-shaped distributor valve is based on the precise fit between the star-shaped rotor and the valve body. When the drive system is started, the star-shaped rotor begins to rotate, distributing the material entering the valve body to multiple outlets along the rotor gap. First, the material enters the valve body through the feed port, and as the rotor rotates, the material is evenly distributed to each outlet channel. The stainless steel sanitary star-shaped distributor valve shows extremely high stability and reliability during long-term operation, reducing the equipment failure rate and maintenance frequency.

The options of the stainless steel sanitary star-shaped distributor valve include:

Different number of channels: select single-channel or multi-channel distribution as needed.

Flow control device: optional flow control function to accurately control the flow of each outlet.

Drive mode: manual, pneumatic or electric drive optional.

Sealing material: different sealing materials can be selected to adapt to different materials.

Cleaning system: equipped with automatic cleaning device to simplify maintenance.

Anti-corrosion coating: for special materials, anti-corrosion coating is optional.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● The rotor of the stainless steel sanitary star-shaped dispensing valve adopts a unique tooth shape design, which not only optimizes the smoothness of material distribution, but also reduces the clogging of granular materials.

● The stainless steel sanitary star-shaped dispensing valve is equipped with an intelligent speed adjustment system, which can automatically adjust the rotor rotation speed according to the viscosity of different materials.

● The internal surface of the stainless steel sanitary star-shaped dispensing valve adopts antimicrobial treatment technology, the surface is smooth and has antibacterial function, which can effectively prevent bacterial growth.

● The stainless steel sanitary star-shaped dispensing valve adopts low-friction materials and advanced sealing technology, and the friction between the valve seat and the rotor is greatly reduced to prevent sealing loss.

● The stainless steel sanitary star-shaped dispensing valve adopts a modular design, which is convenient for replacing or adjusting the number and specifications of the dispensing ports according to production needs.

● The stainless steel sanitary star-shaped dispensing valve is equipped with a multi-way flow adjustment device inside, which can accurately control the flow of each outlet to meet the needs of different material distribution.

Application

Stainless steel sanitary star-shaped dispensing valves are widely used in the following industries: Food industry: used for uniform distribution of liquid and granular materials. Beverage industry: accurate distribution of juice, carbonated beverages and other materials. Pharmaceutical industry: ensure the hygiene and accuracy of the distribution of pharmaceutical raw materials. Cosmetic industry: distribution of emulsions and paste materials. Chemical industry: handling the distribution of chemicals and powder materials. Dairy Industry: Distribution of dairy products such as milk, cream, etc. Tobacco Industry: Distribution of tobacco raw materials or processed materials.

Working Principles

The working principle of the stainless steel sanitary star-shaped distributor valve is based on the precise fit between the star-shaped rotor and the valve body. When the drive system is started, the star-shaped rotor begins to rotate, distributing the material entering the valve body to multiple outlets along the rotor gap. First, the material enters the valve body through the feed port, and as the rotor rotates, the material is evenly distributed to each outlet channel. The stainless steel sanitary star-shaped distributor valve shows extremely high stability and reliability during long-term operation, reducing the equipment failure rate and maintenance frequency.

The options of the stainless steel sanitary star-shaped distributor valve include:

Different number of channels: select single-channel or multi-channel distribution as needed.

Flow control device: optional flow control function to accurately control the flow of each outlet.

Drive mode: manual, pneumatic or electric drive optional.

Sealing material: different sealing materials can be selected to adapt to different materials.

Cleaning system: equipped with automatic cleaning device to simplify maintenance.

Anti-corrosion coating: for special materials, anti-corrosion coating is optional.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● The rotor of the stainless steel sanitary star-shaped dispensing valve adopts a unique tooth shape design, which not only optimizes the smoothness of material distribution, but also reduces the clogging of granular materials.

● The stainless steel sanitary star-shaped dispensing valve is equipped with an intelligent speed adjustment system, which can automatically adjust the rotor rotation speed according to the viscosity of different materials.

● The internal surface of the stainless steel sanitary star-shaped dispensing valve adopts antimicrobial treatment technology, the surface is smooth and has antibacterial function, which can effectively prevent bacterial growth.

● The stainless steel sanitary star-shaped dispensing valve adopts low-friction materials and advanced sealing technology, and the friction between the valve seat and the rotor is greatly reduced to prevent sealing loss.

● The stainless steel sanitary star-shaped dispensing valve adopts a modular design, which is convenient for replacing or adjusting the number and specifications of the dispensing ports according to production needs.

● The stainless steel sanitary star-shaped dispensing valve is equipped with a multi-way flow adjustment device inside, which can accurately control the flow of each outlet to meet the needs of different material distribution.

Application

Stainless steel sanitary star-shaped dispensing valves are widely used in the following industries: Food industry: used for uniform distribution of liquid and granular materials. Beverage industry: accurate distribution of juice, carbonated beverages and other materials. Pharmaceutical industry: ensure the hygiene and accuracy of the distribution of pharmaceutical raw materials. Cosmetic industry: distribution of emulsions and paste materials. Chemical industry: handling the distribution of chemicals and powder materials. Dairy Industry: Distribution of dairy products such as milk, cream, etc. Tobacco Industry: Distribution of tobacco raw materials or processed materials.