| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

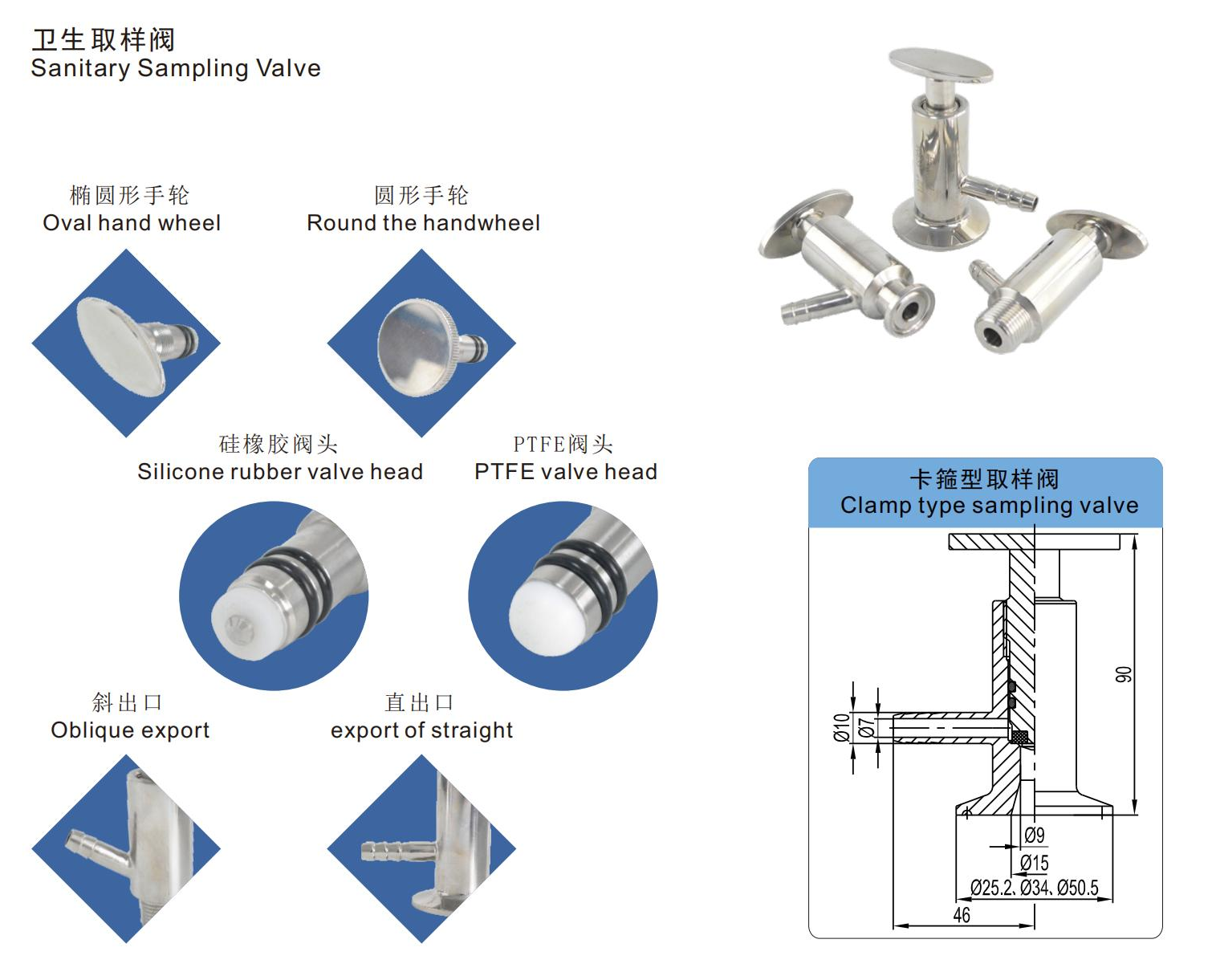

Stainless Steel Sanitary Vacuum Plunger Oil Sampling Valve

The Stainless Steel Sanitary Vacuum Plunger Oil Sampling Valve is a hygienic sampling valve designed to extract oil samples under vacuum conditions. Its plunger mechanism enables controlled, drip-free sampling while maintaining system integrity, preventing contamination, and ensuring accurate analysis in sanitary processing environments.

Working Principles

The Stainless Steel Sanitary Vacuum Plunger Oil Sampling Valve operates by using a spring-loaded or manually actuated plunger to control sample extraction under vacuum or low-pressure conditions. When the plunger is pressed or lifted, an internal seal opens the sampling port, allowing oil to flow into the sampling chamber driven by pressure difference. Once the required sample volume is collected, releasing the plunger immediately closes the valve, isolating the process medium. This design prevents air ingress, backflow, and cross-contamination. The smooth internal surfaces and sanitary seals ensure that no residue remains after sampling, supporting accurate analysis and easy cleaning

Stainless Steel Sampling Valve Specification Chart

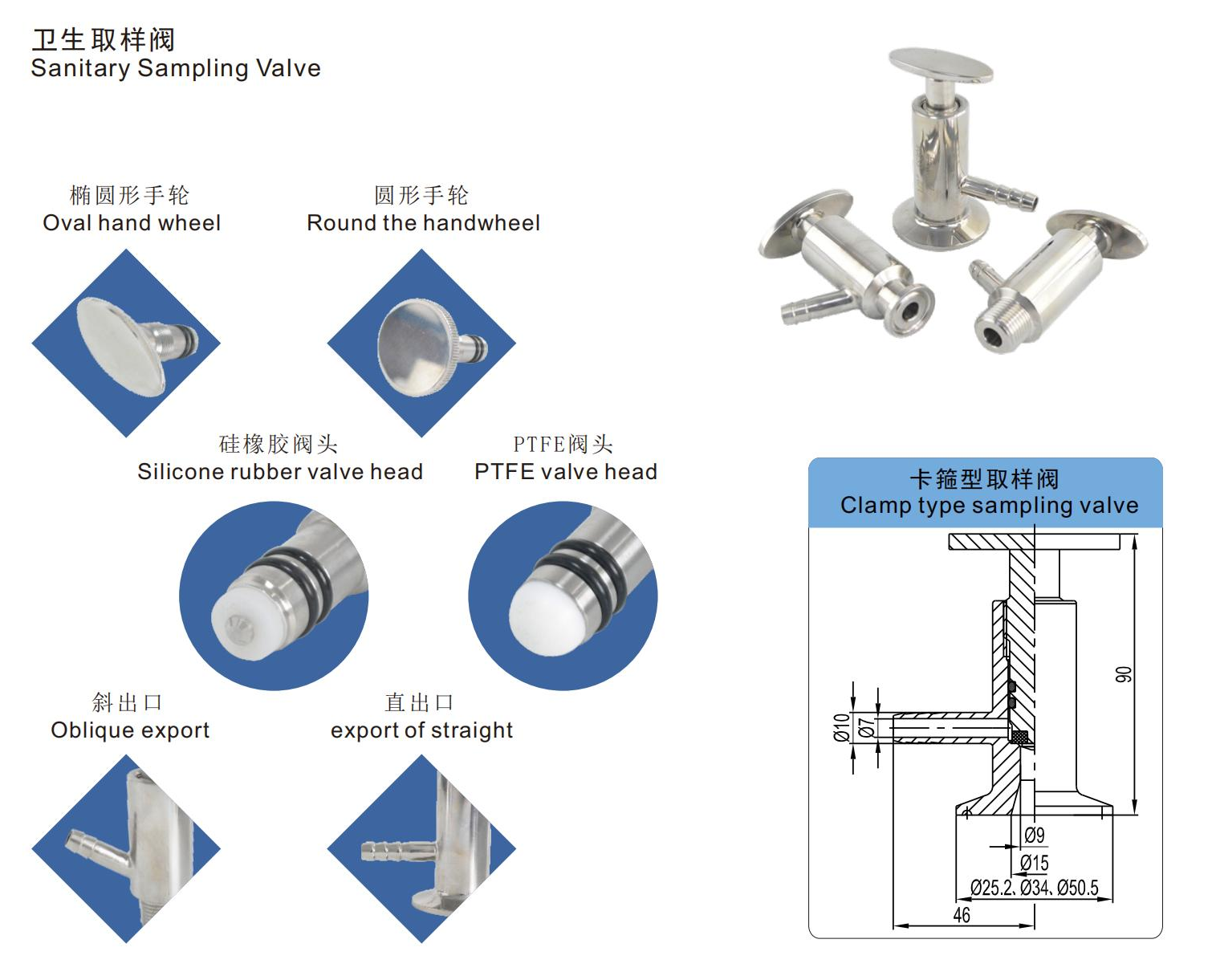

Size | 1/2",1-1/2" |

Connections | thread,clamp,weld |

Max.pressure | 10bar 145psi |

Min.pressure | Vacuum |

Temperature | -10℃ 50 F-120℃/248℃ |

Standard | 3A,ISO,DIN |

Body material | AISI1304, AISI316L |

Seal material | PTFE |

USAGR | Handle quick-opening type, handle wheel fine-turning type, pneumatic and hand-gas integrated four open mode |

Features

PFA-lined internal surfaces provide excellent chemical resistance and prevent oil contamination, ensuring stable performance when handling aggressive or high-purity lubricants under sanitary processing conditions.

Sanitary stainless steel body features smooth finishes and crevice-free construction, supporting hygienic operation, easy cleaning, and full compliance with European sanitary standards.

Precise sampling mechanism allows controlled, repeatable oil extraction without interrupting the main process flow or causing pressure fluctuations in the pipeline.

Leak-tight sealing design ensures safe operation during sampling, minimizing product loss while protecting operators and surrounding equipment from spills or exposure.

Application

The stainless steel sanitary European PFA lined oil sampling valve is widely used in industries requiring clean and accurate oil analysis. Typical applications include pharmaceutical manufacturing for sampling process oils, food and beverage plants for edible oil quality control, chemical processing facilities handling corrosive lubricants, and biotechnology laboratories where contamination-free sampling is essential for safety and compliance.

Working Principles

The Stainless Steel Sanitary Vacuum Plunger Oil Sampling Valve operates by using a spring-loaded or manually actuated plunger to control sample extraction under vacuum or low-pressure conditions. When the plunger is pressed or lifted, an internal seal opens the sampling port, allowing oil to flow into the sampling chamber driven by pressure difference. Once the required sample volume is collected, releasing the plunger immediately closes the valve, isolating the process medium. This design prevents air ingress, backflow, and cross-contamination. The smooth internal surfaces and sanitary seals ensure that no residue remains after sampling, supporting accurate analysis and easy cleaning

Feature and Specification

Stainless Steel Sampling Valve Specification Chart

Size | 1/2",1-1/2" |

Connections | thread,clamp,weld |

Max.pressure | 10bar 145psi |

Min.pressure | Vacuum |

Temperature | -10℃ 50 F-120℃/248℃ |

Standard | 3A,ISO,DIN |

Body material | AISI1304, AISI316L |

Seal material | PTFE |

USAGR | Handle quick-opening type, handle wheel fine-turning type, pneumatic and hand-gas integrated four open mode |

Features

PFA-lined internal surfaces provide excellent chemical resistance and prevent oil contamination, ensuring stable performance when handling aggressive or high-purity lubricants under sanitary processing conditions.

Sanitary stainless steel body features smooth finishes and crevice-free construction, supporting hygienic operation, easy cleaning, and full compliance with European sanitary standards.

Precise sampling mechanism allows controlled, repeatable oil extraction without interrupting the main process flow or causing pressure fluctuations in the pipeline.

Leak-tight sealing design ensures safe operation during sampling, minimizing product loss while protecting operators and surrounding equipment from spills or exposure.

Application

The stainless steel sanitary European PFA lined oil sampling valve is widely used in industries requiring clean and accurate oil analysis. Typical applications include pharmaceutical manufacturing for sampling process oils, food and beverage plants for edible oil quality control, chemical processing facilities handling corrosive lubricants, and biotechnology laboratories where contamination-free sampling is essential for safety and compliance.