| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

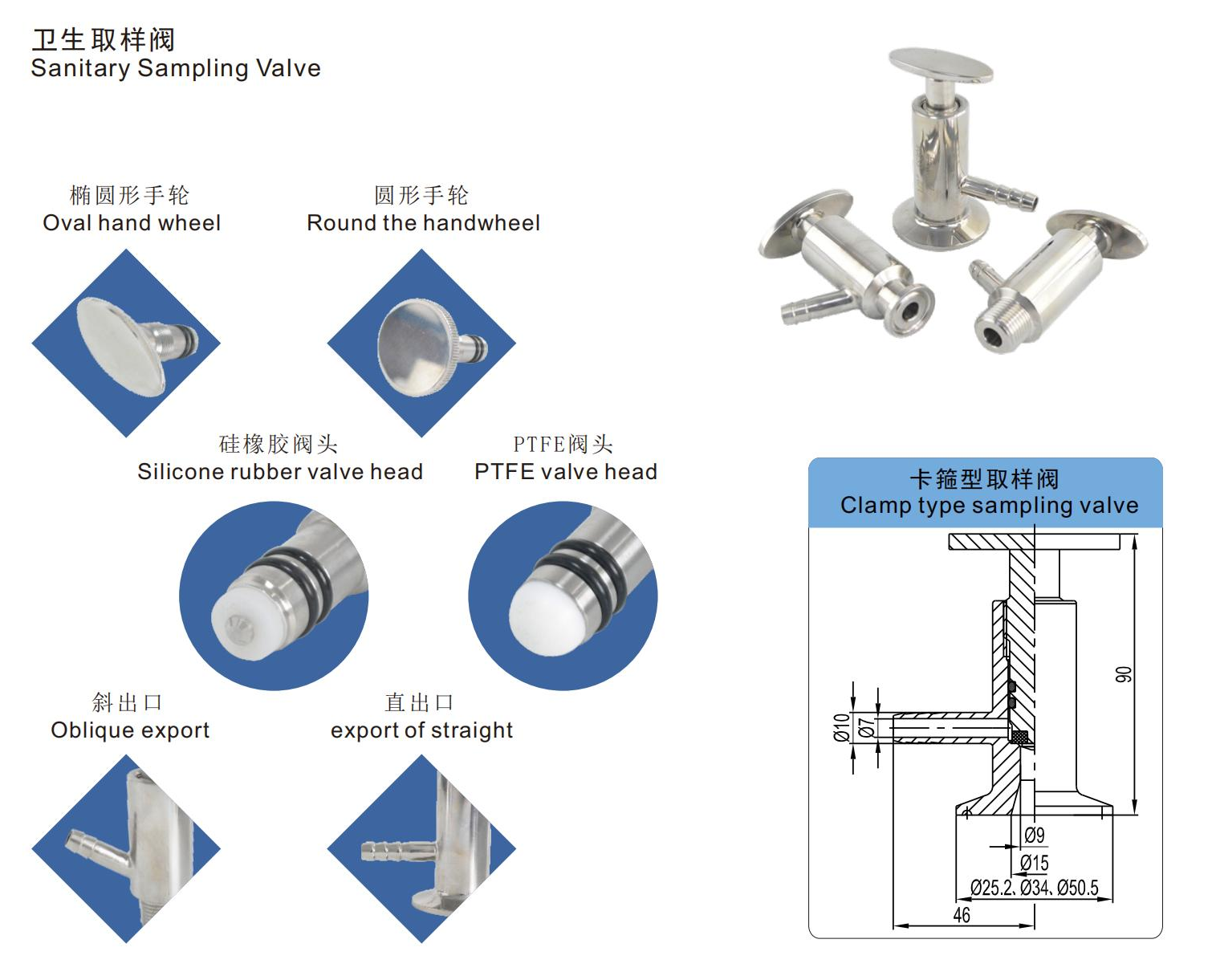

Stainless Steel Sanitary Vacuum Plunger Pfa Lined Sampling Valve

The Stainless Steel Sanitary Vacuum Plunger PFA Lined Sampling Valve is a hygienic valve designed for safe, contamination-free sampling of aggressive or high-purity liquids. Its PFA lining protects against chemical corrosion, while the vacuum plunger mechanism ensures precise, controlled extraction in sanitary processing systems

Working Principles

The Stainless Steel Sanitary Vacuum Plunger PFA Lined Sampling Valve operates by using a vacuum-assisted plunger to draw precise liquid samples from pipelines or tanks. When the plunger is actuated, a controlled vacuum is created in the sampling chamber, allowing the process fluid to flow gently through the PFA-lined passage, which prevents chemical reaction or contamination. Once the desired sample volume is collected, releasing the plunger closes the valve, isolating the sample and preventing backflow or air ingress. The PFA lining ensures chemical resistance and smooth flow, while the stainless steel body provides structural strength and hygienic compatibility, making it ideal for pharmaceutical, chemical, and food-grade applications

Stainless Steel Sampling Valve Specification Chart

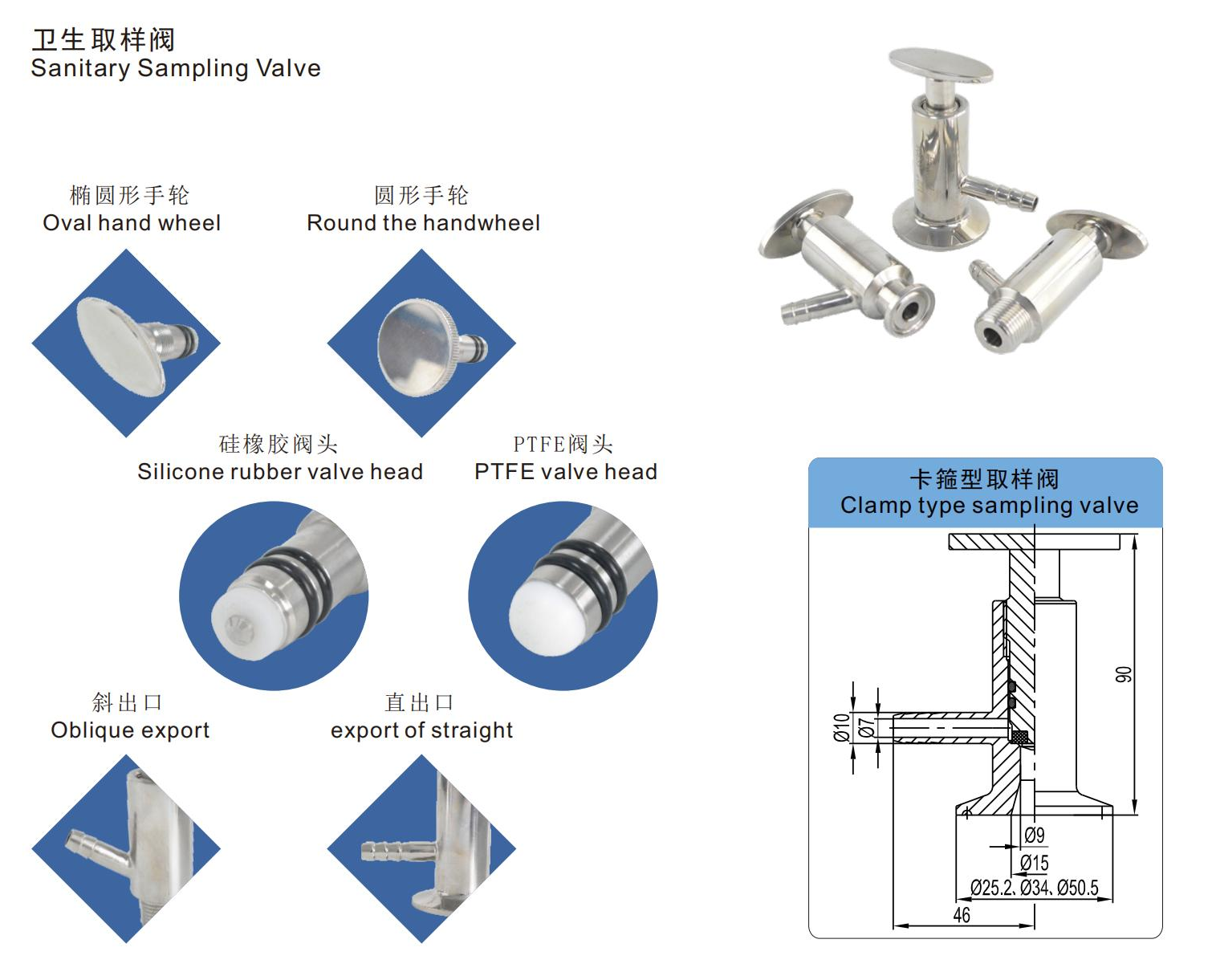

Size | 1/2",1-1/2" |

Connections | thread,clamp,weld |

Max.pressure | 10bar 145psi |

Min.pressure | Vacuum |

Temperature | -10℃ 50 F-120℃/248℃ |

Standard | 3A,ISO,DIN |

Body material | AISI1304, AISI316L |

Seal material | PTFE |

USAGR | Handle quick-opening type, handle wheel fine-turning type, pneumatic and hand-gas integrated four open mode |

Features

Manufactured from sanitary stainless steel with a smooth polished surface, ensuring excellent corrosion resistance, easy cleaning, and full compliance with hygienic standards for oil and dairy processing systems.

Vacuum plunger structure enables gentle and accurate sample extraction without disturbing process pressure, ensuring representative sampling while maintaining product quality and process stability.

Reliable sealing design effectively prevents air ingress and external contamination, protecting sample purity and supporting aseptic operation in sensitive oil and dairy applications.

Compact and ergonomic construction allows easy installation, operation, and maintenance, making it suitable for frequent sampling in pipelines or tanks with limited space.

Application

Stainless steel sanitary vacuum plunger oil dairy sampling valves are commonly used in dairy and edible oil processing plants for hygienic and accurate sampling of milk, yogurt, or cooking oils. They are also applied in food, beverage, and pharmaceutical production lines where aseptic sampling is critical to ensure product quality, prevent contamination, and maintain compliance with sanitary standards during quality control and laboratory testing.

Working Principles

The Stainless Steel Sanitary Vacuum Plunger PFA Lined Sampling Valve operates by using a vacuum-assisted plunger to draw precise liquid samples from pipelines or tanks. When the plunger is actuated, a controlled vacuum is created in the sampling chamber, allowing the process fluid to flow gently through the PFA-lined passage, which prevents chemical reaction or contamination. Once the desired sample volume is collected, releasing the plunger closes the valve, isolating the sample and preventing backflow or air ingress. The PFA lining ensures chemical resistance and smooth flow, while the stainless steel body provides structural strength and hygienic compatibility, making it ideal for pharmaceutical, chemical, and food-grade applications

Feature and Specification

Stainless Steel Sampling Valve Specification Chart

Size | 1/2",1-1/2" |

Connections | thread,clamp,weld |

Max.pressure | 10bar 145psi |

Min.pressure | Vacuum |

Temperature | -10℃ 50 F-120℃/248℃ |

Standard | 3A,ISO,DIN |

Body material | AISI1304, AISI316L |

Seal material | PTFE |

USAGR | Handle quick-opening type, handle wheel fine-turning type, pneumatic and hand-gas integrated four open mode |

Features

Manufactured from sanitary stainless steel with a smooth polished surface, ensuring excellent corrosion resistance, easy cleaning, and full compliance with hygienic standards for oil and dairy processing systems.

Vacuum plunger structure enables gentle and accurate sample extraction without disturbing process pressure, ensuring representative sampling while maintaining product quality and process stability.

Reliable sealing design effectively prevents air ingress and external contamination, protecting sample purity and supporting aseptic operation in sensitive oil and dairy applications.

Compact and ergonomic construction allows easy installation, operation, and maintenance, making it suitable for frequent sampling in pipelines or tanks with limited space.

Application

Stainless steel sanitary vacuum plunger oil dairy sampling valves are commonly used in dairy and edible oil processing plants for hygienic and accurate sampling of milk, yogurt, or cooking oils. They are also applied in food, beverage, and pharmaceutical production lines where aseptic sampling is critical to ensure product quality, prevent contamination, and maintain compliance with sanitary standards during quality control and laboratory testing.