Stainless Steel Sanitary Welded Plastic Pneumatic Diaphragm Valve

The Stainless Steel Sanitary Welded Plastic Pneumatic Diaphragm Valve is an automated hygienic valve featuring a welded stainless steel body and a lightweight plastic pneumatic actuator. It provides clean, reliable flow control using a diaphragm seal, making it suitable for sanitary fluid processing systems.

Working Principles

The Stainless Steel Sanitary Welded Plastic Pneumatic Diaphragm Valve operates by using compressed air to drive a plastic pneumatic actuator, which moves a stem connected to a flexible diaphragm. When air pressure is applied, the actuator pushes the diaphragm downward to close the valve or lifts it to open the flow path. The diaphragm separates the process fluid from the actuator and internal mechanical components, ensuring hygienic and contamination-free operation. The welded stainless steel body provides a smooth, clean flow channel with minimal dead space, reducing residue buildup. This pneumatic mechanism delivers fast response, reliable sealing, and consistent performance in sanitary processing environments.

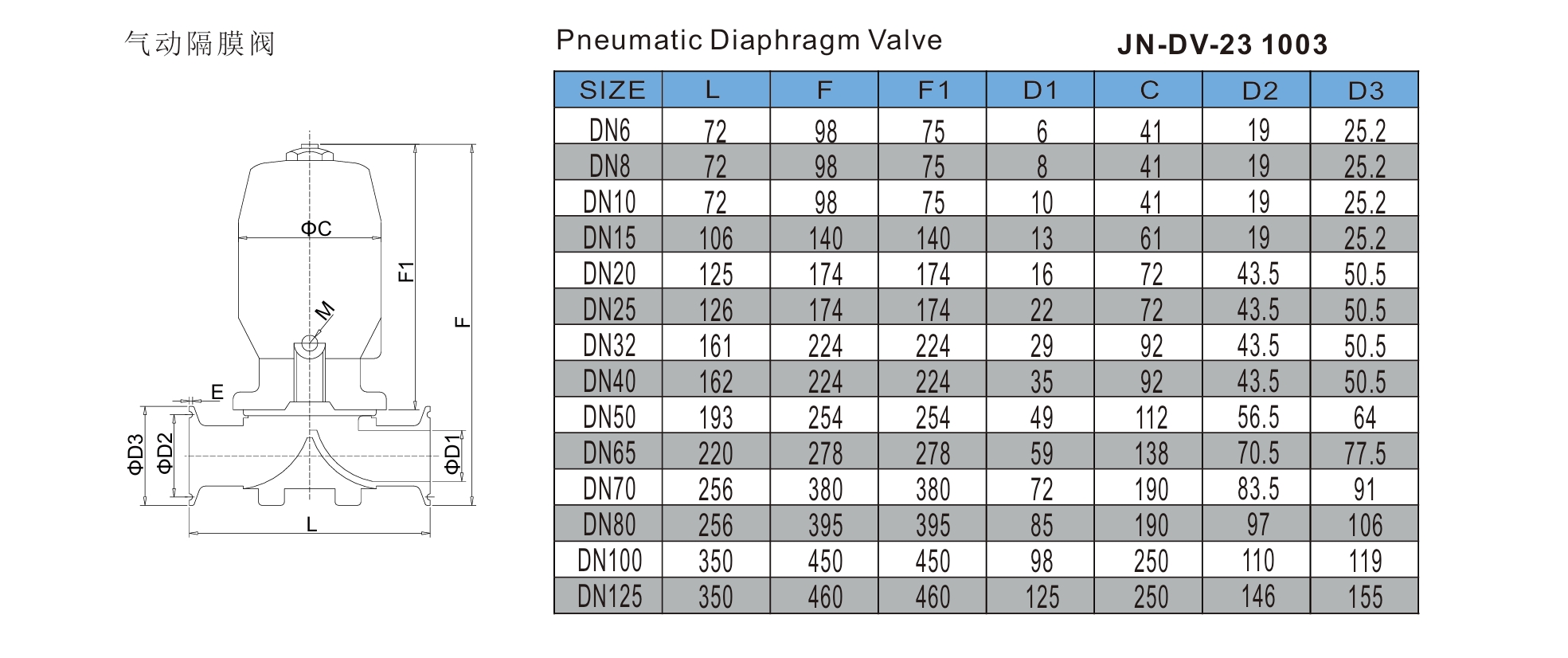

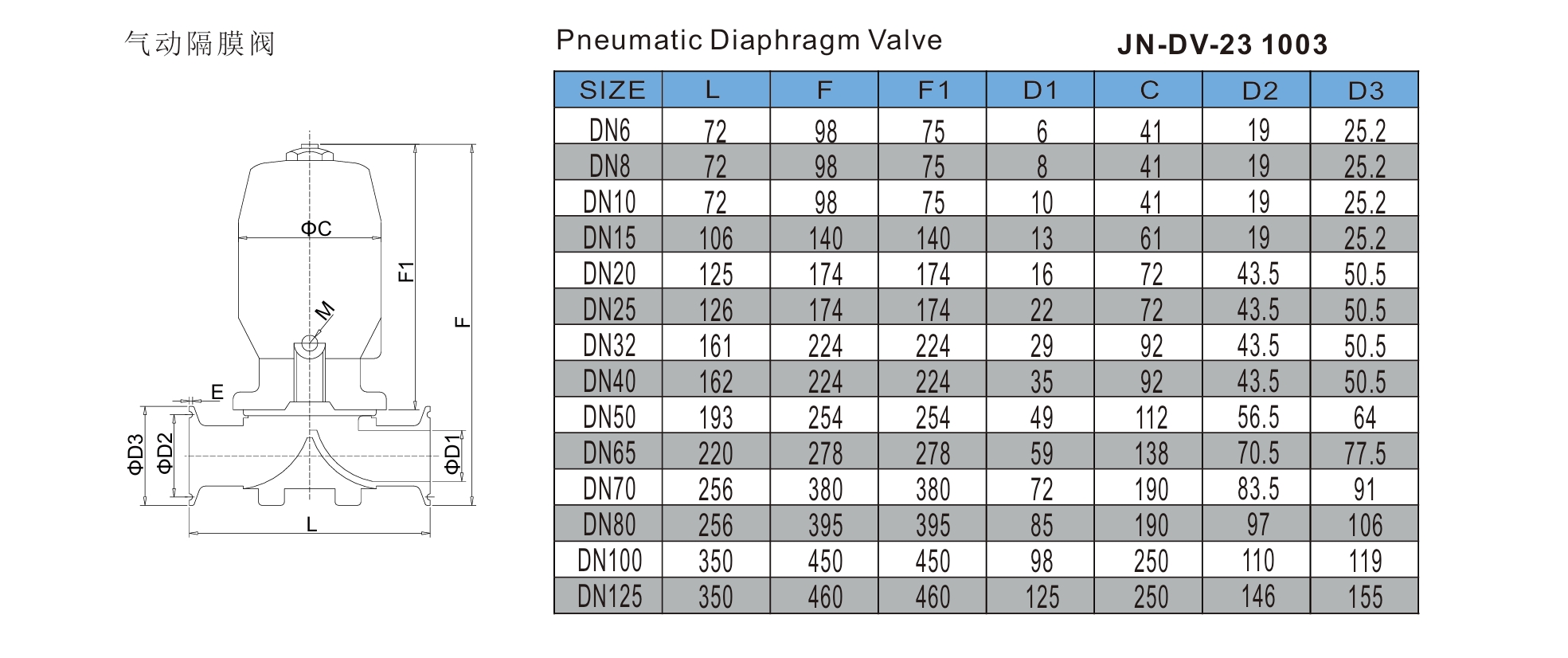

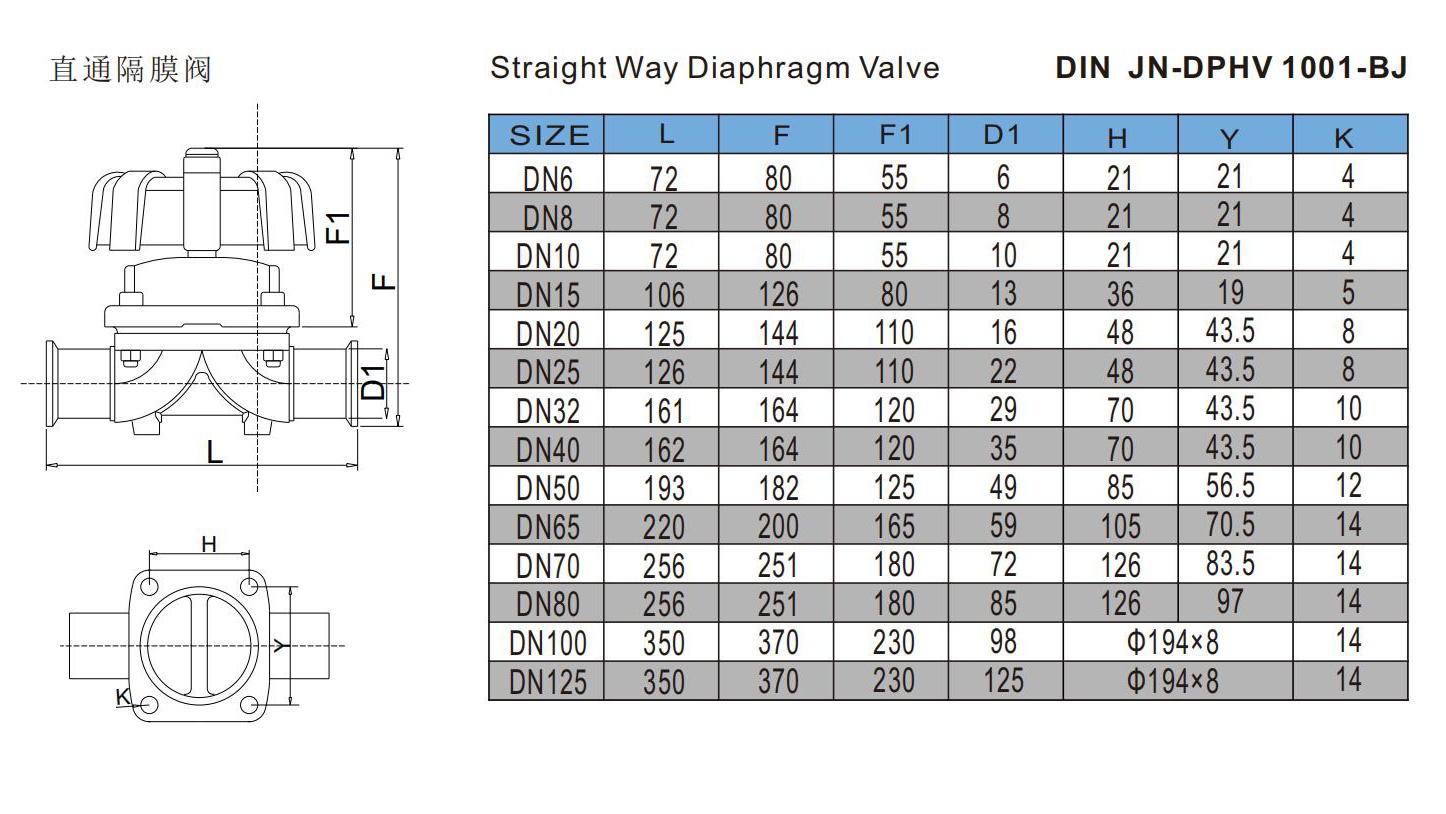

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure

|

10 Bar

|

Temperature range |

-10° ~ +120°C or higher upon request

|

Sizes available

|

1" to 6"

|

End connection

|

Clamp, Weld, Flange, Thread |

Body material

|

AISI 316L

|

Body structure |

2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves

|

Seal material

|

Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane

|

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

The lightweight plastic pneumatic actuator provides fast, reliable automation, reducing overall valve weight and improving installation flexibility in sanitary piping systems.

The welded stainless steel body ensures a smooth, crevice-free flow path with high structural integrity, minimizing contamination risk and supporting hygienic operation.

The diaphragm design isolates the fluid from moving parts, delivering leak-free sealing and protecting the actuator from process media.

Quick pneumatic response enables efficient on/off or throttling control, making the valve suitable for automated sanitary processes.

Corrosion-resistant materials enhance durability and ensure long service life in food, pharmaceutical, and biotech applications.

The compact structure simplifies installation in tight spaces while maintaining excellent flow performance and easy maintenance.

Application

Stainless Steel Sanitary Welded Plastic Pneumatic Diaphragm Valves are widely used in industries that require strict hygiene, smooth flow control, and reliable separation between the fluid and actuator components. They are commonly applied in the food and beverage industry for processing dairy, beer, and juices; in pharmaceuticals for handling purified water and sensitive media; and in biotechnology for sterile fluid transfer. These valves are also used in cosmetics manufacturing and chemical production where corrosion resistance and contamination prevention are essential