| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary straight-through filter is a device used to filter solid impurities in the pipeline. The structure is usually made of stainless steel and meets the hygiene standards. The stainless steel sanitary straight-through filter is usually used in the pipeline system of the food, beverage, pharmaceutical and other industries. It is mainly installed in the process of fluid transportation, especially at the inlet and outlet of the pipeline, branch point or the front end of the equipment. Its function is to ensure that the impurities in the fluid are effectively removed, prevent the pipeline system and equipment from being blocked or damaged, and ensure the purity of the fluid and the stable operation of the system. According to the design and application requirements, there are several common types of stainless steel sanitary straight-through filters: single-tube filter, double-tube filter, self-cleaning filter, simple filter, precision filter.

JONENG

8421219990

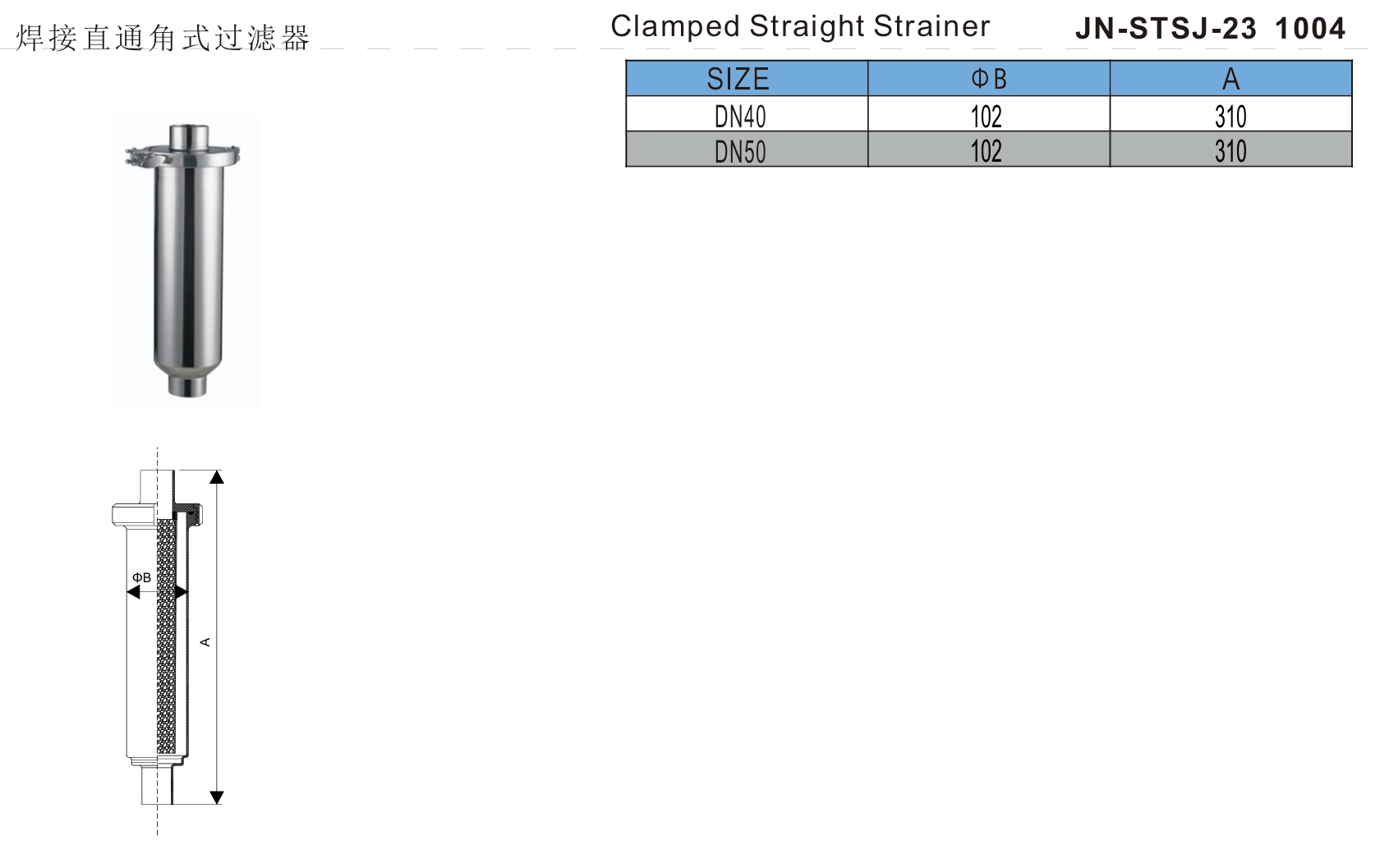

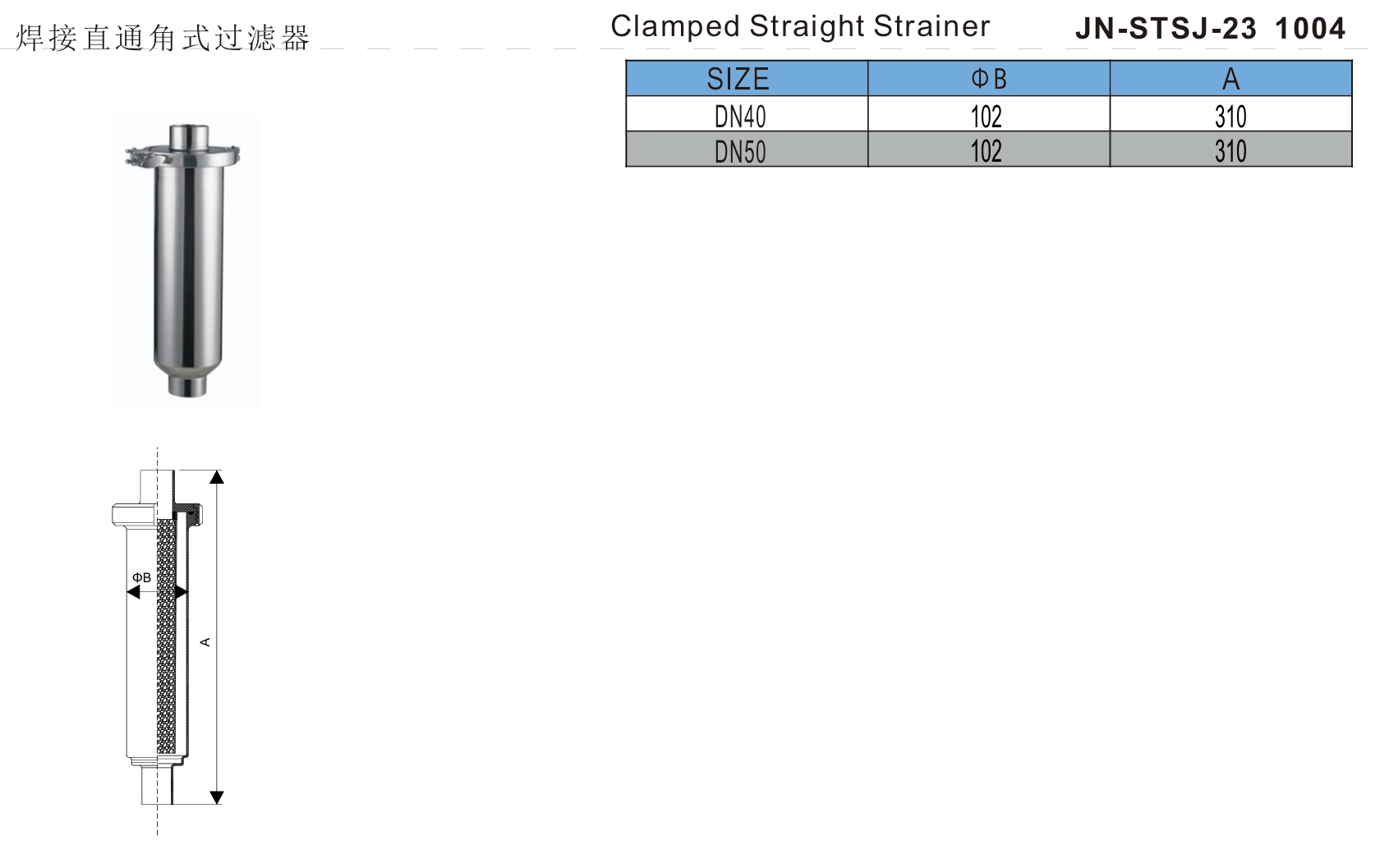

Stainless Steel Sanitary Welded Single Cylinder Straight Filter Element

The design of the stainless steel sanitary straight-through filter is to ensure that the fluid in the pipeline system can flow smoothly without being contaminated by impurities. Through the straight-through structure, it minimizes the resistance to fluid flow, so that the fluid is not disturbed and maintains efficient flow. Its design emphasizes high cleanliness and easy cleaning, and is particularly suitable for industries with extremely high hygiene requirements, such as food, beverage, pharmaceutical, etc. Through effective filtration, impurities are prevented from damaging the equipment or affecting product quality, ensuring the long-term stable operation of the system. Overall, its purpose is to improve production efficiency while ensuring the hygiene and safety of the product.

Working Principles

The working principle of the stainless steel sanitary straight-through filter is based on the physical filtration process. After the fluid enters the filter, it flows through the filter screen or filter element through a straight-through pipe. Impurities are intercepted by the filter screen, and clean fluid passes smoothly. When the filter screen accumulates enough impurities, the pressure difference increases, reminding the operator to clean or replace the filter element. In some automatic cleaning filters, the system regularly backwashes the filter screen through mechanical or hydraulic devices to automatically remove accumulated impurities and maintain efficient operation of the filter. Using stainless steel sanitary straight-through filters can reduce equipment failures and pipeline damage caused by impurities, thereby reducing maintenance costs and system downtime.

The options for stainless steel sanitary straight-through filters include:

Filter element material: such as stainless steel mesh, polyester, ceramic, etc.

Filtration accuracy: Filter screens with different pore sizes can be selected according to needs.

Cleaning method: manual cleaning or automatic self-cleaning function.

Connection method: such as quick installation, flange or threaded connection.

Filtration form: single-tube or double-tube design.

Dimensions: customized according to pipeline and flow requirements.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary straight-through filter adopts a non-contact filtering structure design, and the contact surface between the filter and the fluid is small, which reduces the chance of contact between pollutants and the filter.

● The stainless steel sanitary straight-through filter can choose different filter mesh precisions according to needs, and configure the filtering precision from coarse to fine to meet different filtering requirements.

● The stainless steel sanitary straight-through filter adopts a double sealing ring design to ensure that the sealing is enhanced under high pressure or high flow rate.

● The stainless steel sanitary straight-through filter is equipped with a cleaning window, and the user can directly observe the cleanliness of the filter element, which is convenient for judging when to clean it.

● The stainless steel sanitary straight-through filter adopts a fluid dynamics optimization design to minimize the pressure loss when the fluid passes through the filter and reduce fluid resistance.

● The stainless steel sanitary straight-through filter is equipped with an automatic sewage discharge device to clean the filter element through reverse flow to reduce manual intervention.

Application

Stainless steel sanitary straight-through filters are mainly used in the following industries: Food and beverage industry: used to filter liquids to ensure hygiene and safety. Pharmaceutical industry: used for high-purity filtration in drug production. Bioengineering: used for filtration of cell culture and biological products. Cosmetics industry: used for fine filtration of raw materials and finished products. Electronics industry: used for ultrapure water preparation to ensure pollution-free. Chemical industry: used for filtration and treatment of corrosive liquids. Water treatment industry: used for filtration and purification of drinking water and wastewater.

Working Principles

The working principle of the stainless steel sanitary straight-through filter is based on the physical filtration process. After the fluid enters the filter, it flows through the filter screen or filter element through a straight-through pipe. Impurities are intercepted by the filter screen, and clean fluid passes smoothly. When the filter screen accumulates enough impurities, the pressure difference increases, reminding the operator to clean or replace the filter element. In some automatic cleaning filters, the system regularly backwashes the filter screen through mechanical or hydraulic devices to automatically remove accumulated impurities and maintain efficient operation of the filter. Using stainless steel sanitary straight-through filters can reduce equipment failures and pipeline damage caused by impurities, thereby reducing maintenance costs and system downtime.

The options for stainless steel sanitary straight-through filters include:

Filter element material: such as stainless steel mesh, polyester, ceramic, etc.

Filtration accuracy: Filter screens with different pore sizes can be selected according to needs.

Cleaning method: manual cleaning or automatic self-cleaning function.

Connection method: such as quick installation, flange or threaded connection.

Filtration form: single-tube or double-tube design.

Dimensions: customized according to pipeline and flow requirements.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary straight-through filter adopts a non-contact filtering structure design, and the contact surface between the filter and the fluid is small, which reduces the chance of contact between pollutants and the filter.

● The stainless steel sanitary straight-through filter can choose different filter mesh precisions according to needs, and configure the filtering precision from coarse to fine to meet different filtering requirements.

● The stainless steel sanitary straight-through filter adopts a double sealing ring design to ensure that the sealing is enhanced under high pressure or high flow rate.

● The stainless steel sanitary straight-through filter is equipped with a cleaning window, and the user can directly observe the cleanliness of the filter element, which is convenient for judging when to clean it.

● The stainless steel sanitary straight-through filter adopts a fluid dynamics optimization design to minimize the pressure loss when the fluid passes through the filter and reduce fluid resistance.

● The stainless steel sanitary straight-through filter is equipped with an automatic sewage discharge device to clean the filter element through reverse flow to reduce manual intervention.

Application

Stainless steel sanitary straight-through filters are mainly used in the following industries: Food and beverage industry: used to filter liquids to ensure hygiene and safety. Pharmaceutical industry: used for high-purity filtration in drug production. Bioengineering: used for filtration of cell culture and biological products. Cosmetics industry: used for fine filtration of raw materials and finished products. Electronics industry: used for ultrapure water preparation to ensure pollution-free. Chemical industry: used for filtration and treatment of corrosive liquids. Water treatment industry: used for filtration and purification of drinking water and wastewater.